Method for thermally adjusting width of crystallizer and crystalline wedge-shaped blank of crystallizer

A crystallizer and thermal width adjustment technology, which is applied in the field of metallurgical continuous casting, can solve the problems such as difficult to guarantee the safety of width adjustment and slow width adjustment process, so as to stabilize the quality of slab, increase the productivity of casting machine, and increase the metal yield and the effect on production availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

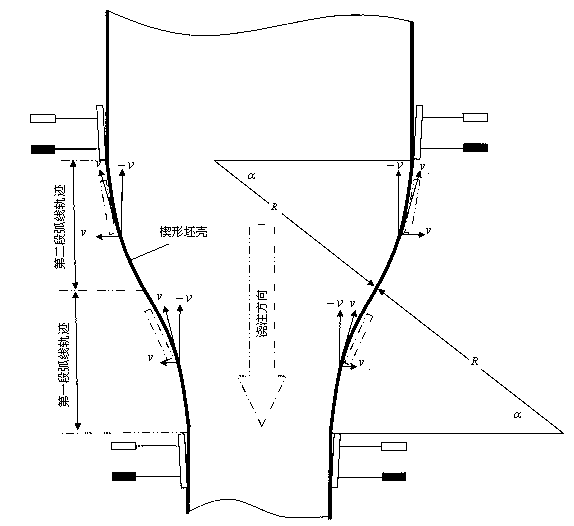

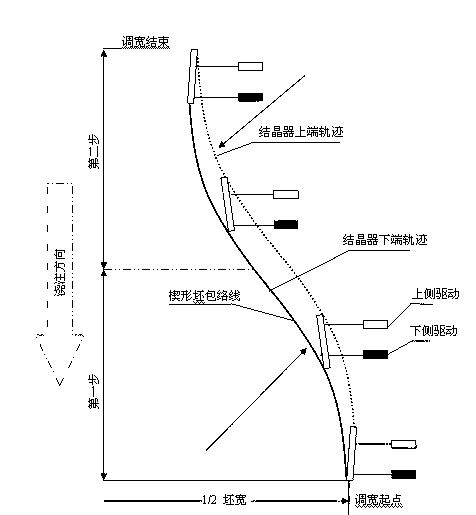

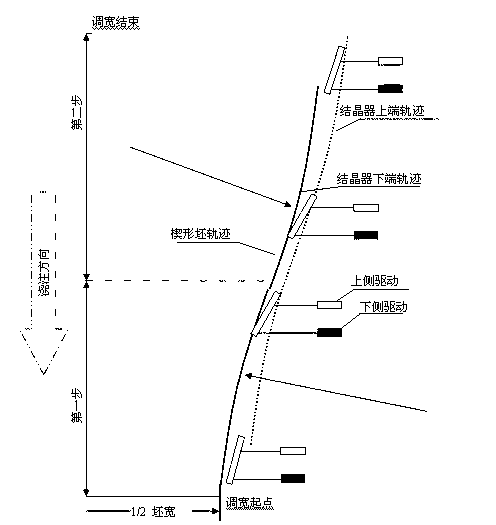

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

[0036] A crystallizer thermal width adjustment method, the specific steps of crystallizer thermal width adjustment are as follows:

[0037] 1) Position the narrow side of the crystallizer at the initial position;

[0038] 2) The top of the narrow side of the crystallizer moves in a uniformly accelerated curve relative to the casting slab, and then moves in a uniformly decelerated curve after reaching the middle preset position, and turns to step 3 during the movement of the top of the narrow side);

[0039] 3) After the bottom end of the narrow side of the crystallizer moves at the top for a period of time, it moves according to the track at the top of the narrow side described in step 2);

[0040] 4) Both the top and bottom of the narrow side of the crystallizer reach the target setting position, and the width adjustment process is completed.

[0041] The principle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com