Overall heating automatic welding process of spud leg main coil of offshore drilling platform and special tool of overall heating automatic welding process

An offshore drilling platform and integral heating technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high load bearing, low welding efficiency and high technical requirements, and achieve practical production methods, production efficiency and welding. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

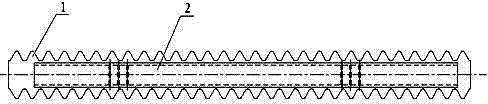

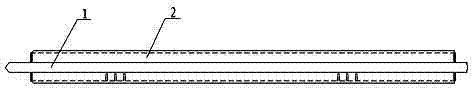

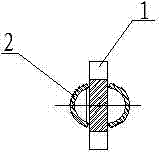

Image

Examples

Embodiment 1

[0025] Embodiment 1: Welding the main spiral tube of the pile leg with a rack thickness of 127mm and a chord wall thickness of 38mm.

[0026] Put the racks and chords to be welded into the electric furnace for a preheating, the preheating temperature is 150-200°C, and the whole is heated through. Then use special tooling to position the rack and the chords on both sides, and use flux-cored wire gas shielded welding for root welding. Two people are used to weld symmetrically and in the same direction. The welding temperature is 150-230°C and the welding speed is 430-456mm / min. Properly grind the bottom weld seam, conduct thermal magnetic particle inspection after grinding, and enter the next process after passing the inspection. The racks and chords are placed in the electric furnace for secondary preheating, the preheating temperature is 150-200°C, and the whole is thoroughly heated. Then carry out secondary welding, use automatic submerged arc welding to fill and cover the r...

Embodiment 2

[0027] Embodiment 2: Welding the main spinning tube of the pile leg with a rack thickness of 152.4mm and a chord wall thickness of 38mm.

[0028] Put the racks and chords to be welded into the electric furnace for a preheating, the preheating temperature is 170-230°C, and the whole is heated through. Then use special tooling to position the rack and the chords on both sides, and use flux-cored wire gas shielded welding for root welding. Two people are used for symmetrical welding in the same direction. The welding temperature is 150-230°C and the welding speed is 420-440mm / min. Properly grind the bottom weld seam, conduct thermal magnetic particle inspection after grinding, and enter the next process after passing the inspection. The racks and chords are placed in the electric furnace for secondary preheating, the preheating temperature is 170-230°C, and the whole is thoroughly heated. Then carry out secondary welding, use automatic submerged arc welding to fill and cover the...

Embodiment 3

[0029] Embodiment 3: Welding the main spiral pipe of the pile leg with the thickness of the rack being 177.8mm and the wall thickness of the chord pipe being 68-93mm.

[0030] Put the racks and chords to be welded into the electric furnace for a preheating, the preheating temperature is 180-250°C, and the whole is heated through. Then use special tooling to position the rack and the chords on both sides, and use flux-cored wire gas shielded welding for root welding. Two people are used to weld symmetrically and in the same direction. The welding temperature is 150-230°C and the welding speed is 400-430mm / min. Properly grind the bottom weld seam, conduct thermal magnetic particle inspection after grinding, and enter the next process after passing the inspection. The racks and chords are placed in the electric furnace for secondary preheating, the preheating temperature is 180-250°C, and the whole is thoroughly heated. Then carry out secondary welding, use automatic submerged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com