Parallel connection type permanent magnetic hybrid magnetic levitation device for magnetic levitation train

A maglev train and parallel technology, applied in electric vehicles, vehicle parts, transportation and packaging, etc., can solve the problem of difficult electromagnetic control, and achieve the effects of reducing control difficulty, preventing suction dead, and improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

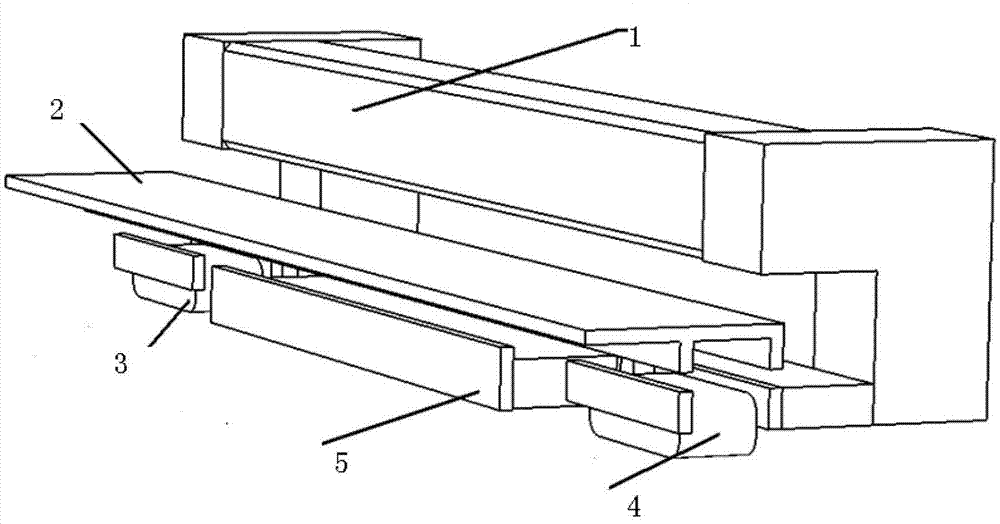

[0027] use Figure 1 In a bogie, two permanent magnetic levitation modules and four electromagnetic levitation modules are grouped and arranged in parallel along the direction of the F-shaped track and facing the F-shaped track; the suspension frame is 3 meters long and has a self-weight of 65,000 N. The rated load is 25,000 N, the length of the permanent magnetic levitation module is 1.56 meters, and the length of the electromagnetic levitation module is 0.5 meters.

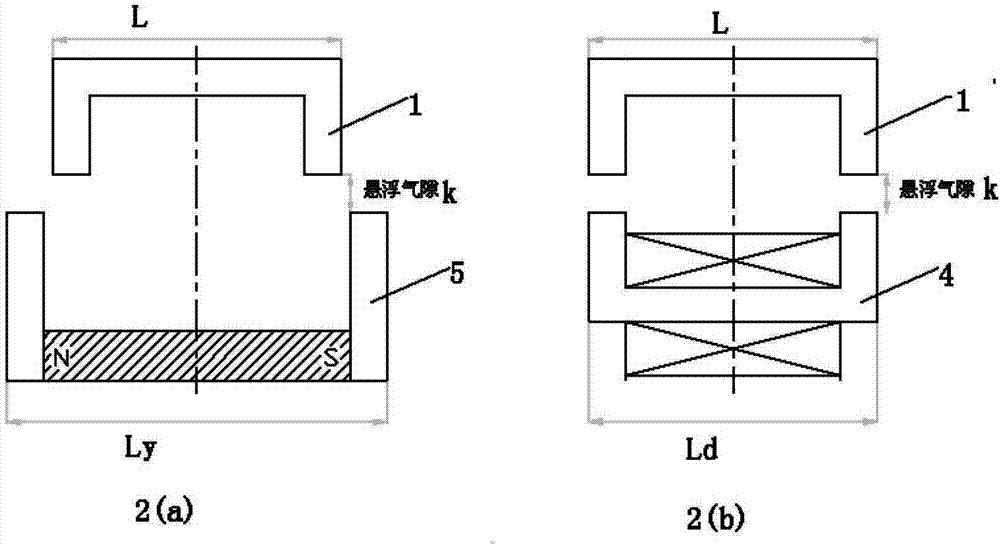

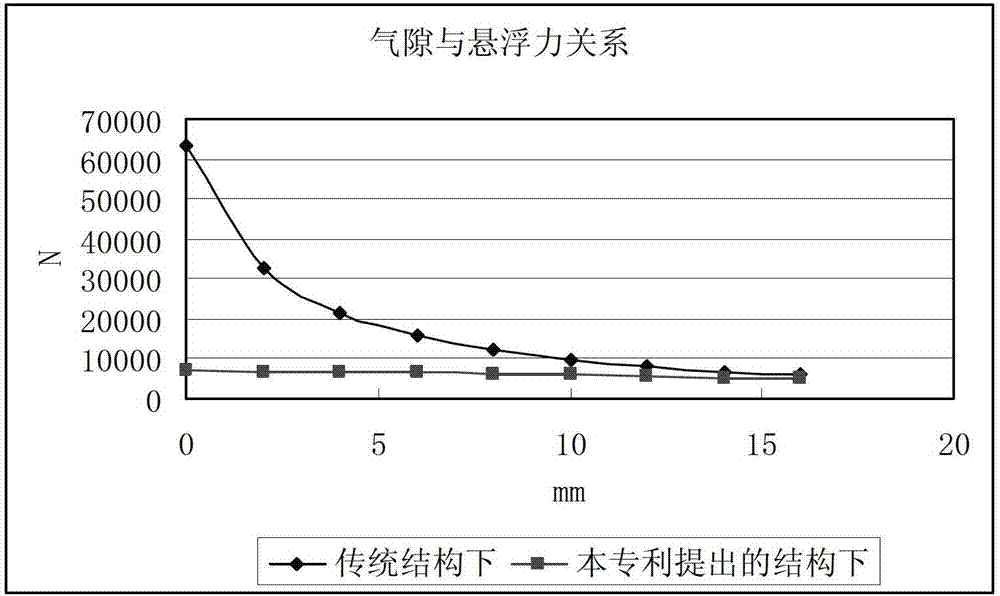

[0028] The width of the permanent magnetic levitation module is not equal to the width of the F-shaped track, and the main levitation force is provided by the permanent magnetic levitation module. See the attached size parameters for the specific implementation selection Figure 4 , where: M=71mm; D=100mm; G takes 0, 10, 20mm. Wherein the width of the electromagnetic levitation module is equal to the width of the F-shaped track. Auxiliary and adjustable levitation forces are provided by the electromagnetic le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com