Solid-web H-shaped honeycomb steel beam for polygonal hole

A polygonal hole and H-beam technology, which is applied to joists, girders, truss beams, etc., can solve the problem of unreasonable stress on the hole angle of polygonal hole honeycomb beams, increased production process and production cost, and the loss of circular hole honeycomb beams. and other problems, to achieve the effect of increasing structural beauty, reasonable stress and improving stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

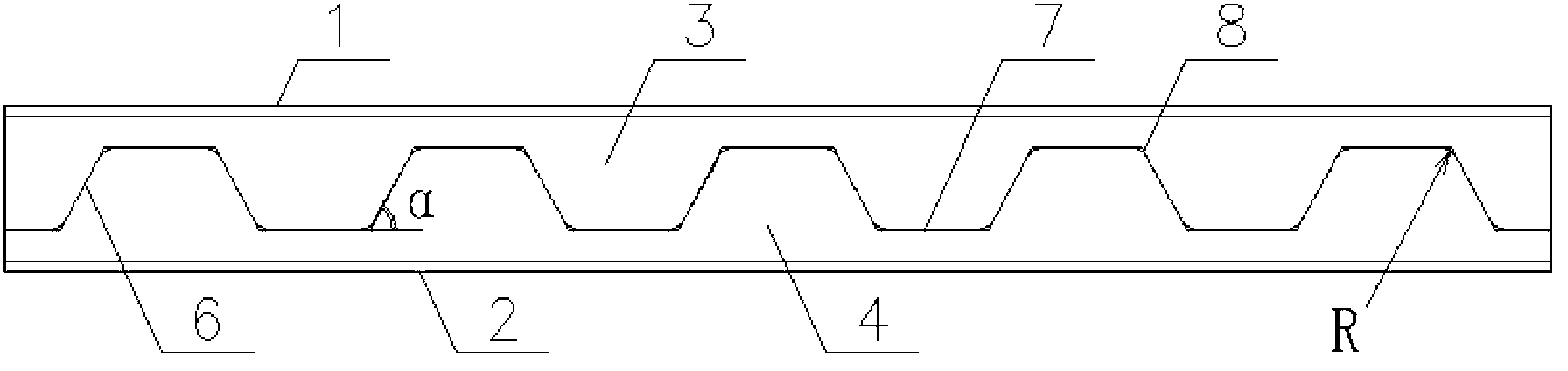

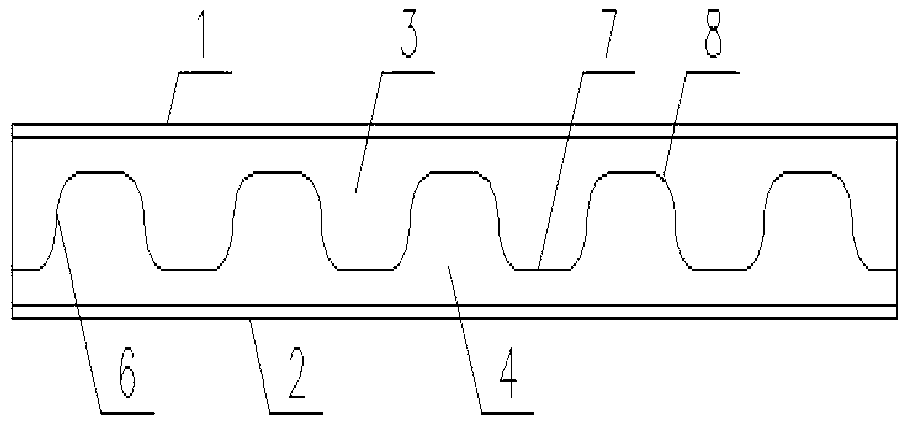

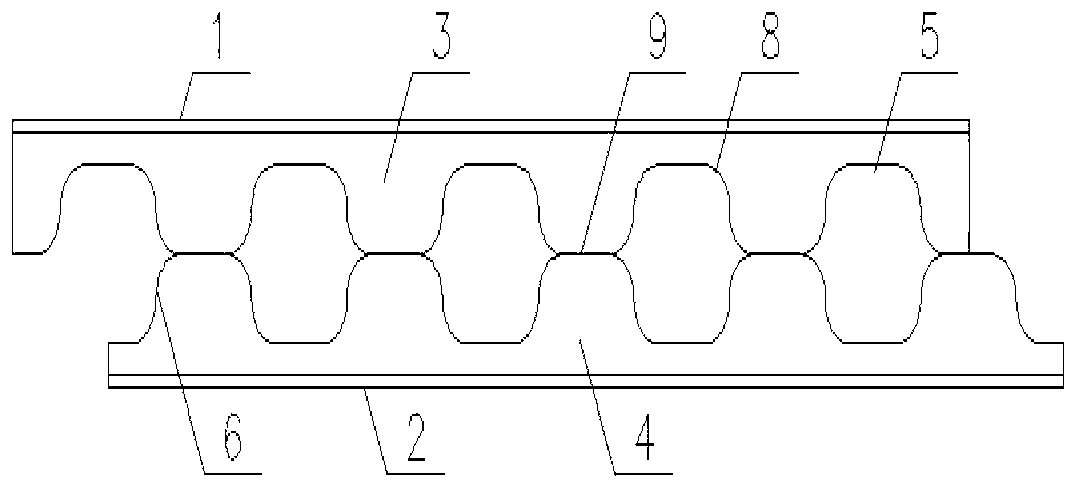

[0040] Embodiment 1, a kind of polygonal hole solid web H-shaped honeycomb steel beam, such as figure 1 , figure 2 , image 3 As shown, it is a honeycomb steel beam with rounded rectangular holes, including upper flange 1, lower flange 2, upper web 3, lower web 4, upper flange 1 and upper web 3 connected, lower flange 2 and lower web 4 connection, the upper web 3 and the lower web 4 are provided with a straight line segment 7 parallel to the axis of the steel beam, an oblique line segment 6 at 45°<α<90° with the axis of the steel beam, a straight line segment 7 and an oblique line segment 6 tangential arc lines 8, the straight line segment 7, the oblique line segment 6, and the arc line 8 are made by cutting the web along the straight line segment 7, the oblique line segment 6, and the arc line 8 respectively. The straight line segment 7 of the upper web 3 and the straight line segment 7 of the lower web 4 are dislocated and matched to form a web butt weld 9 by welding, and...

Embodiment 2

[0041] Embodiment 2, a kind of polygonal hole solid web H-shaped honeycomb steel beam, such as Figure 4 , Figure 5 As shown, it is a honeycomb steel beam with hexagonal holes with rounded corners. Others refer to Embodiment 1, and will not be repeated here.

Embodiment 3

[0042]Embodiment 3, a kind of polygonal hole solid web H-shaped honeycomb steel beam, such as Figure 6 to Figure 11 As shown, the steel beam is composed of two different types of H-shaped steel beams cut and welded. The width and thickness of the upper flange 1 and the lower flange 2 of the H-shaped honeycomb steel beam are different, or the upper web 3 and the lower web 4 different heights. By cutting two solid-web H-shaped steel beams with different cross-sections according to the same curve, one of them is used to make the upper flange 1 and upper web 3 after cutting, and the other is used to make the lower flange 2 and Lower web 4. For other references to Embodiment 1, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com