A grouting casing for integral reinforcement of steel members

A technology of steel components and casings, applied in building construction, building maintenance, construction, etc., can solve the problems of structural safety and normal use function, and achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

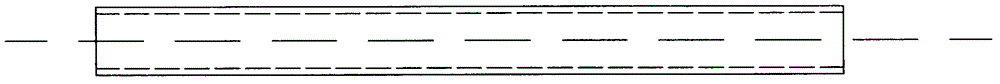

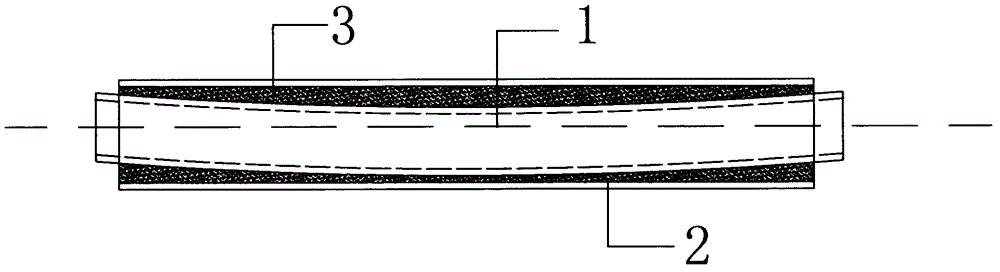

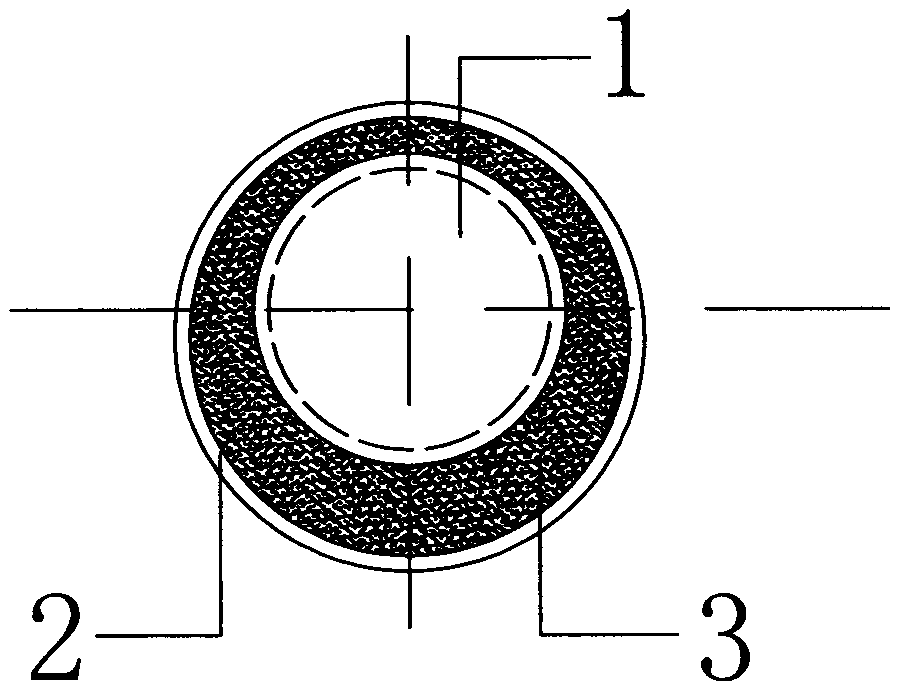

[0011] figure 1 A schematic diagram of a steel member in normal use, with the steel member straight and free from bending or twisting. figure 2 For the steel member 1 that is integrally bent, the steel member 1 is bent so that the entire steel member 1 forms an arc. The straight sleeve 2 is set within the bending range of the steel member 1. During installation, the straight sleeve 2 can be cut into two parts in the axial direction in advance, and the two parts of the straight sleeve are respectively buckled outside the steel member 1 and assembled On-site connection, the connection method can be existing connection methods such as welding or bolts, and of course other methods can also be used to cover the casing 2 outside the steel member 1. The construction accuracy of the suit is not high, and it only needs to be inserted with a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com