Construction method of a tunnel waterproof system

A construction method and technology for tunnels, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of fast aging, high repair rate, and low reliability of waterproof systems, achieve excellent deformation resistance, and improve yield. , good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

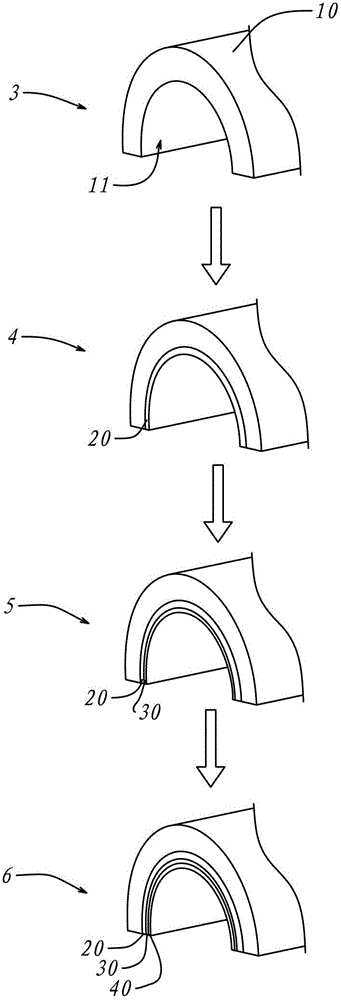

[0031] Such as figure 1 , a construction method of a tunnel waterproof system, the construction method includes four main steps as shown in the figure, they are:

[0032] Surface treatment step 1: process the inner wall part of the tunnel that needs to be waterproofed. In this embodiment, the inner wall that needs to be waterproofed is the inner wall of the surrounding rock 10, so the loose layer, dust and unstable particles on the surface are removed to make It tends to be flattened, and ensure that its surface has a moderately rough rough surface 11, which is convenient to be closely matched with other materials; the surrounding rock 10 targeted by this embodiment has basically no obvious visible leakage, and its geological characteristics It shows a relatively high-quality and stable structure, so no special treatment is required for obvious leakage.

[0033] Rigid sealing step 4: After the surface treatment step 1 is completed, the prepared self-repairing waterproofing ag...

Embodiment 2

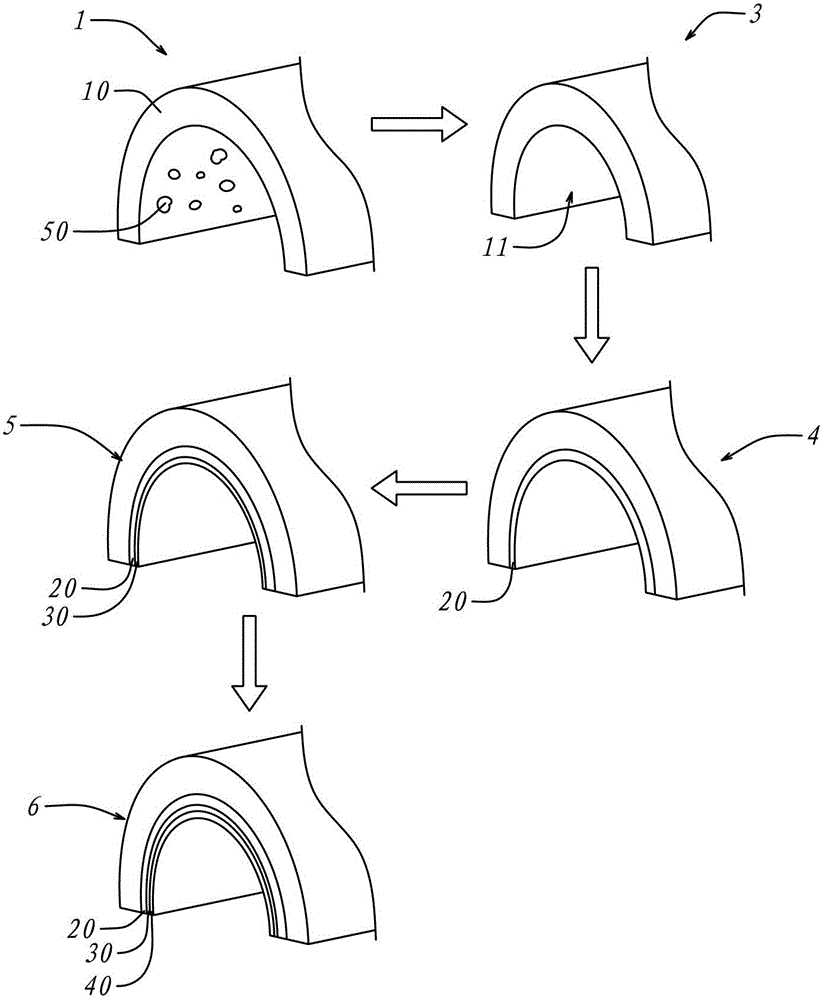

[0041] Such as figure 2 , this embodiment still includes surface treatment step 3, rigid treatment step 4, flexible treatment step 5, and outer lining step 6 in sequence relative to embodiment one; the treatments aimed at in these same steps are basically the same; wherein there are some The difference is:

[0042] In rigid treatment step 4, the above-mentioned self-repairing waterproofing agent is not applied in the form of brushing, but in the form of spraying, and is sprayed on the rough surface 11 with a mechanical nozzle, so that the self-repairing waterproofing agent impacts and penetrates into the rough surface 11. Micropores and / or cracks; it can be seen that this spraying method can significantly improve the forming efficiency of the rigid waterproof membrane 20, and its thickness uniformity is easy to control, and its penetration effect and matching strength are good.

[0043] In this embodiment, there is a local grouting step 1 before the surface treatment step 3,...

Embodiment 3

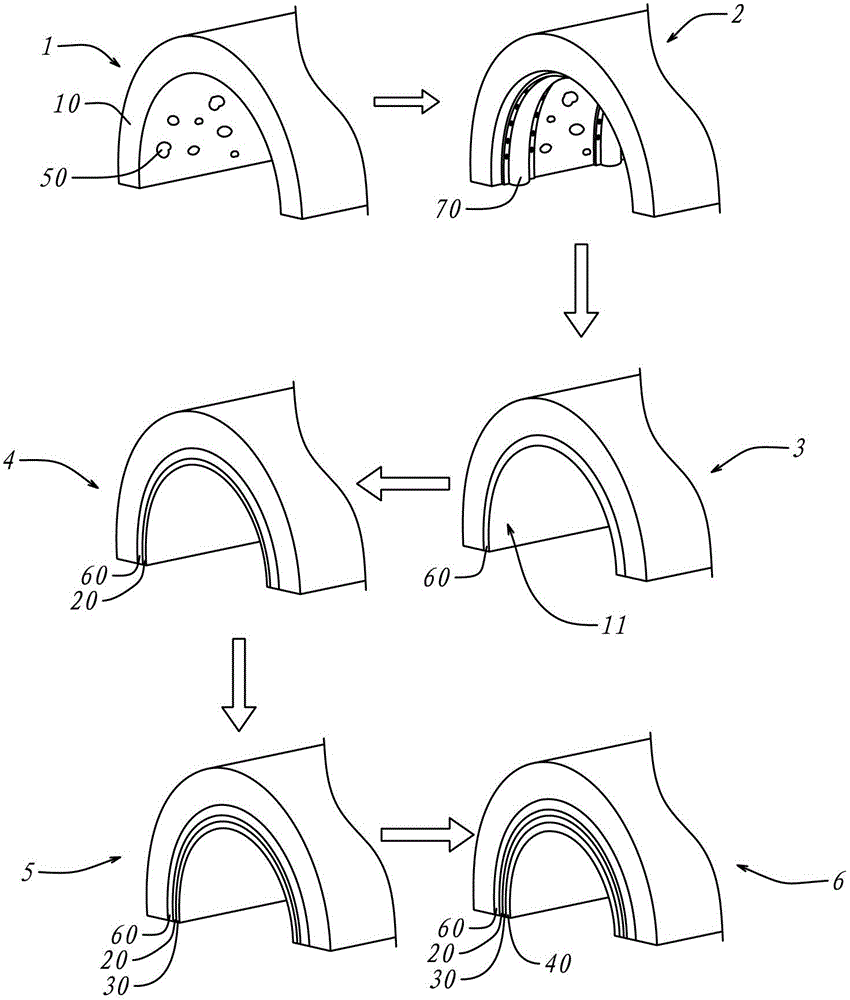

[0047] Such as image 3 , is the construction step diagram of Embodiment 3 of the present invention, and this embodiment is especially suitable for the section where the surrounding rock 10 address conditions are too poor:

[0048] Compared with the second embodiment, the early treatment of the surrounding rock 10 in this embodiment still has a local grouting step 1, and its plugging agent 50 still treats some inner walls with relatively small and obvious seepage, but because these sections are motion 10 The quality of the sealant is too poor, and a relatively stable inner wall cannot be obtained by the plugging agent 50 alone to place the composite waterproof layer. Therefore, after the local grouting step 1, there is also a dredging step 2 and a lining step.

[0049] After the local grouting step 1, part of the leakage fissures are blocked. At the same time, this step will reserve the position of those who cannot be blocked. At this position, the dredging step 2 will fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com