Pipe-segment quick-unloading device for slope tunnel borer

A technology for a tunnel boring machine and an unloading device, which is applied to tunnels, tunnel linings, shaft equipment and other directions, can solve problems such as the inability to meet the driving speed of the inclined shaft tunnel boring machine and the long time required for hoisting by a segment crane, and achieve structural Simple, prevent axial bending deformation, quick unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

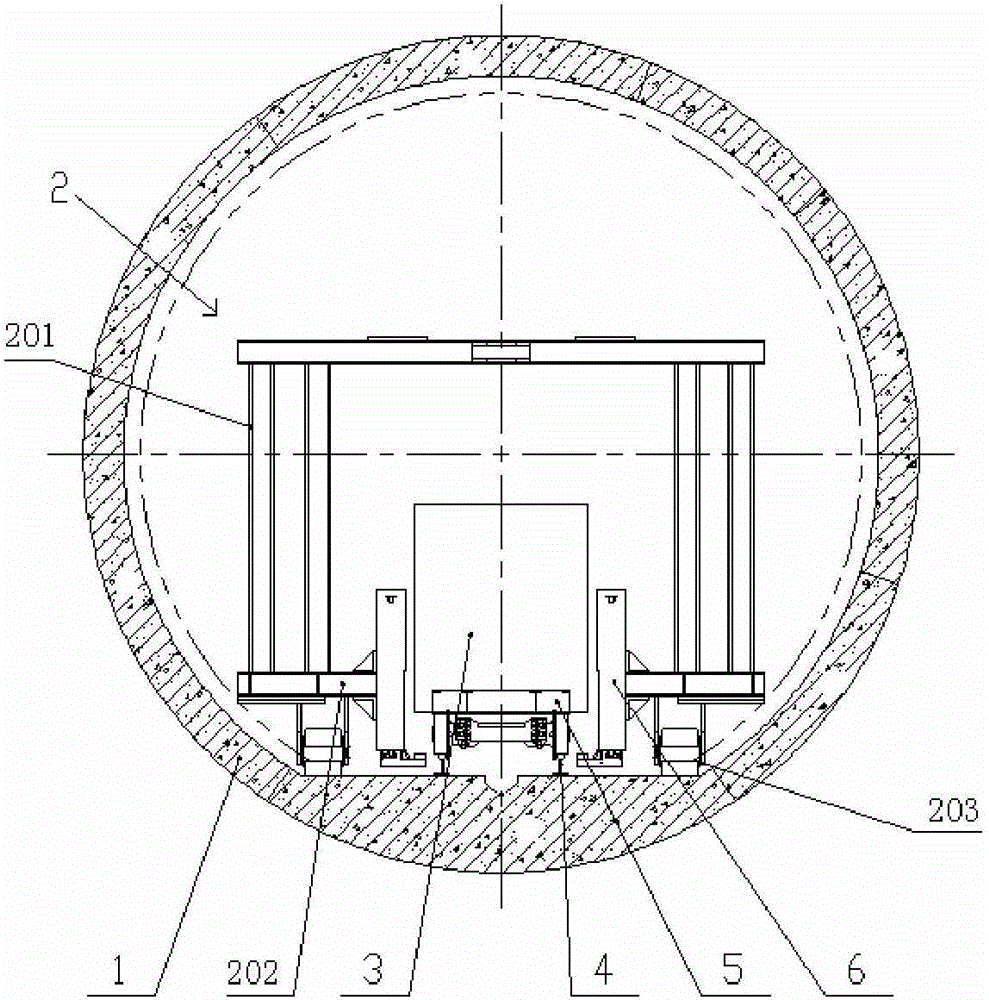

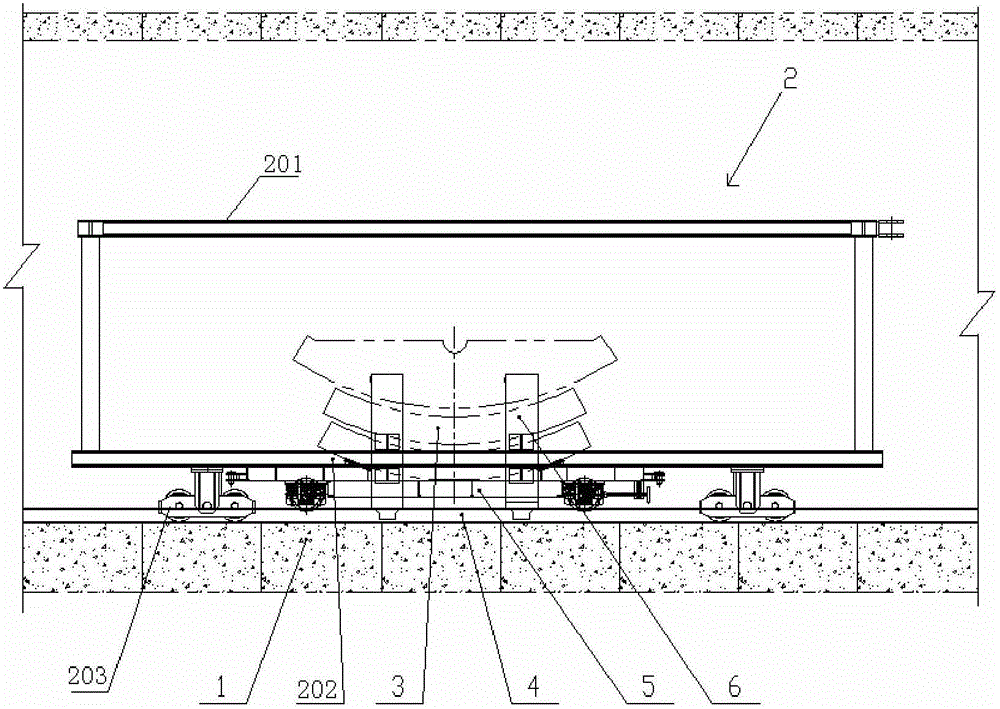

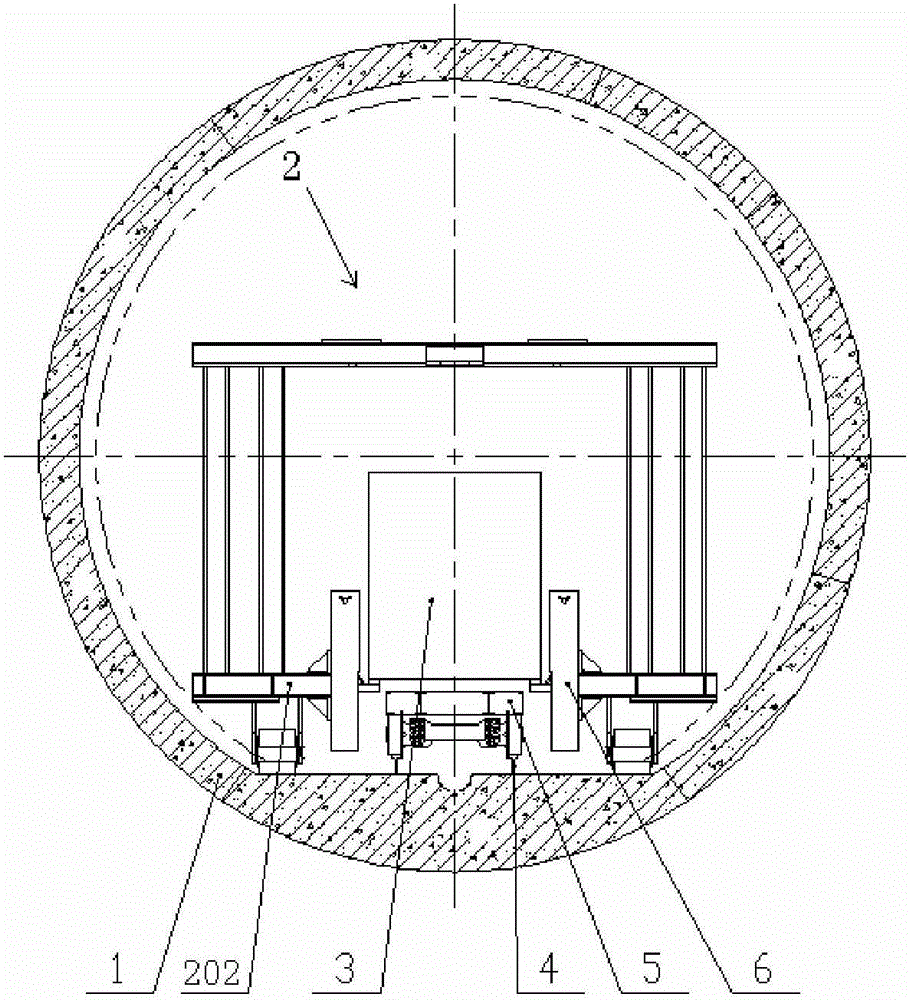

[0016] Such as figure 1 with figure 2 As shown, the segment quick unloading device of the inclined shaft tunnel boring machine includes the back supporting trolley 2 of the tunnel boring machine and the lifting unloader 6 arranged on the back supporting trolley 2; The two connected car bodies 202 arranged in parallel at a certain interval are provided with wheels 203 under the car body 202; the unloader 6 is 4 correspondingly located on the inner side of the interval on the two car bodies, and the unloader 6 is matched with the rear The trolley 2 is welded together (or bolted together).

[0017] The unloader 6 includes a first connecting shaft 601 , a fixed box 602 , a push rod 603 , a lifting arm 604 with a hook 6041 at the lower end, a second connecting shaft 605 and a roller assembly 606 . The upper end of the push rod 603 is hinged with the fixed box 602 through the first connecting shaft 601; the lower end of the push rod 603 is hinged with the lifting arm 604 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com