Diesel engine cylinder oil immersion antirust method capable of reducing oil immersion waste

A diesel engine and cylinder block technology, applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of uneconomical, increased space and operators, waste and other problems, and achieve the effect of satisfying mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be made below in conjunction with the accompanying drawings and the oil-immersed rust prevention method for diesel engine cylinder blocks that can reduce oil-immersion waste according to the present invention.

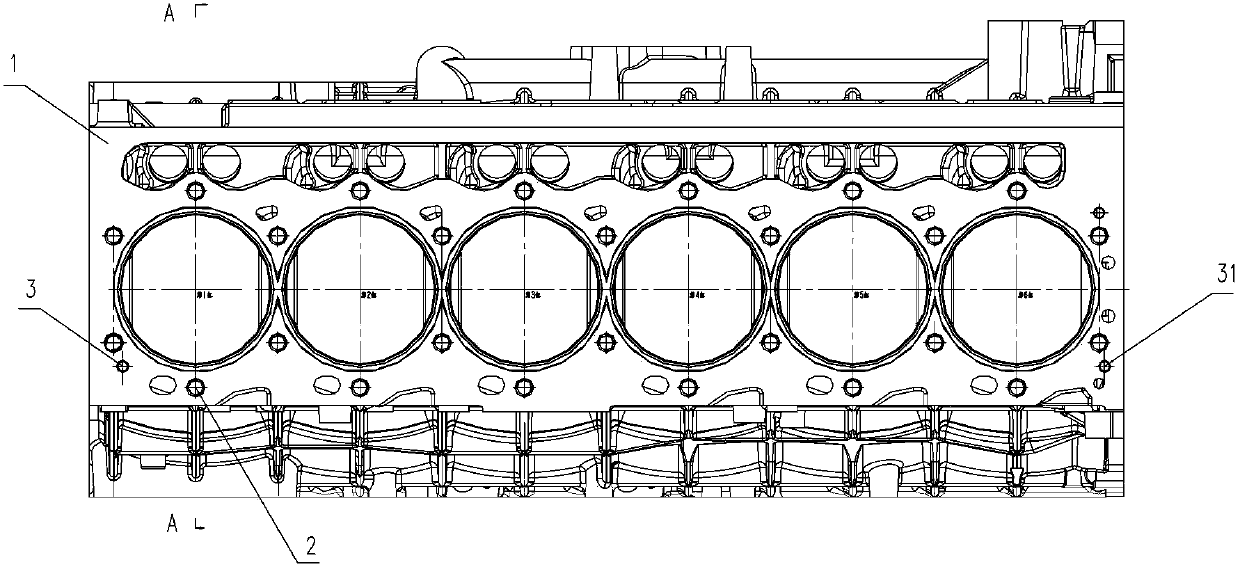

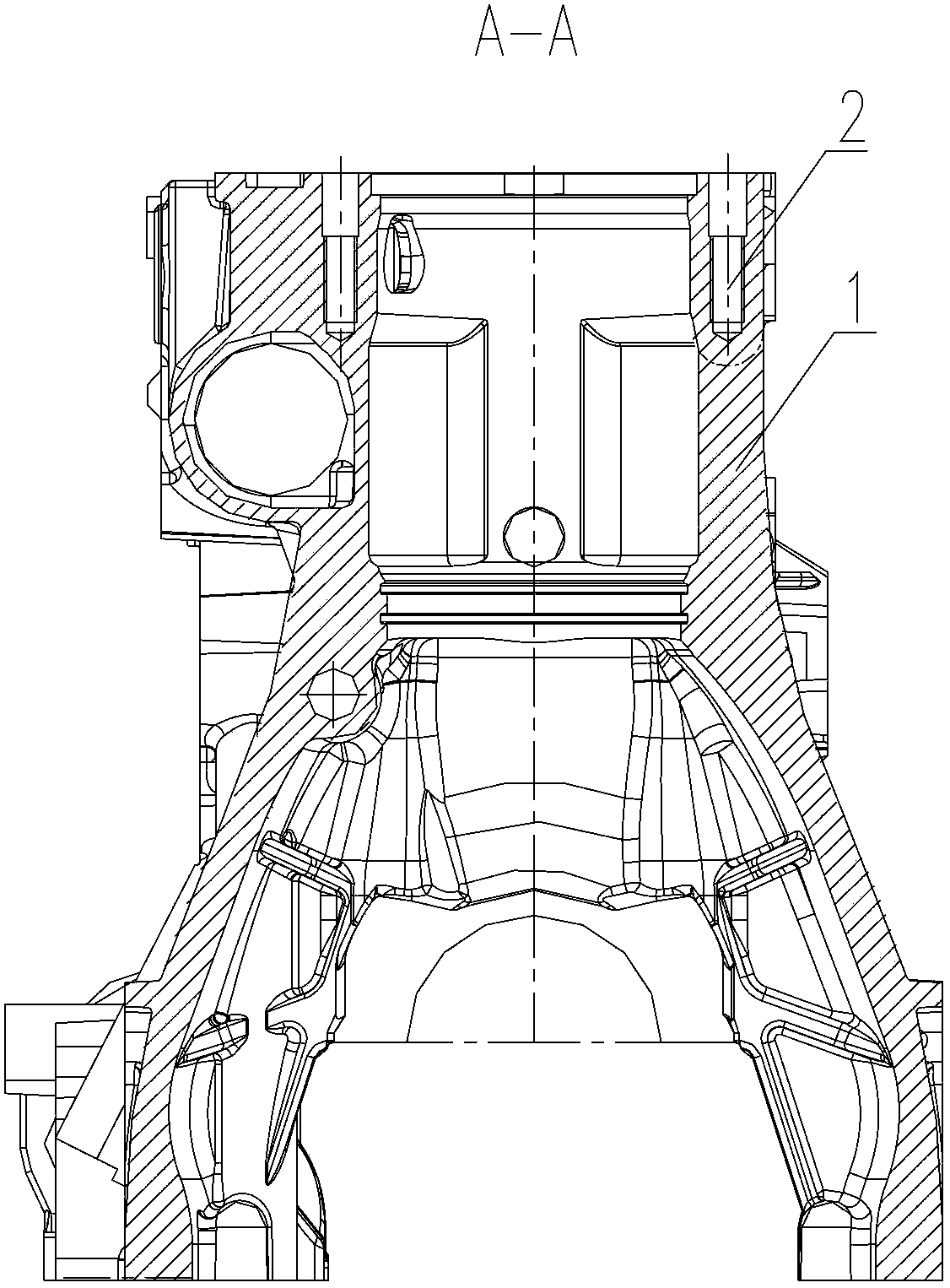

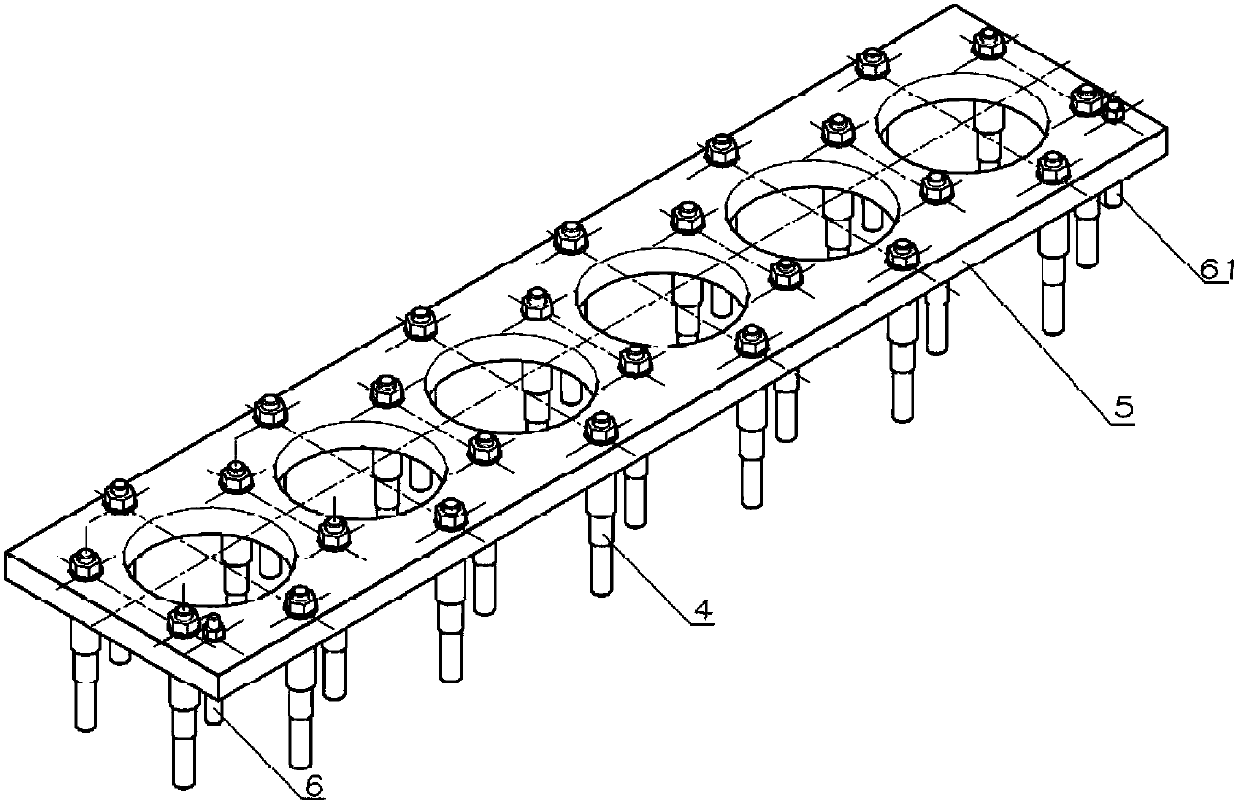

[0019] see figure 1 , figure 2 , image 3 As shown, it includes a diesel engine cylinder block 1, a cylinder head bolt blind hole 2, a first positioning hole 3, a second positioning hole 31, a cylinder pin 4, a plastic mold 5, a first positioning pin 6, and a second positioning pin 61.

[0020] The oil immersion antirust method of the diesel engine cylinder block that can reduce the oil immersion waste of the present invention comprises the following steps:

[0021] 1. Pour the anti-rust oil just enough to submerge the cylinder block 1 of the diesel engine into the fuel tank;

[0022] 2. Insert cylindrical pins 4 that fit in clearance with cylinder head bolt blind holes 2 into the cylinder head bolt blind holes 2 on the top surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com