High-performance resin special for automobile exterior trimming and preparation method thereof

A high-performance, automotive technology, applied in the field of modified materials, can solve the problems of severe weather resistance, difficult weather resistance, aesthetics and cost balance, achieve excellent rigidity and toughness, reduce poor process and post-processing technology, and material costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

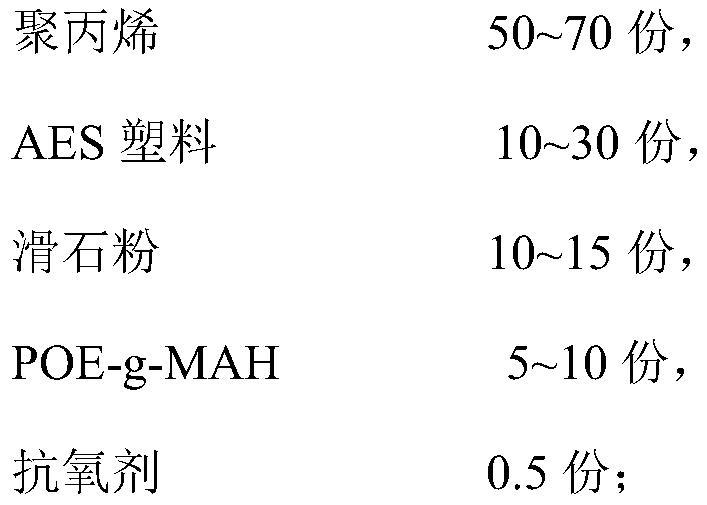

Method used

Image

Examples

Embodiment 1

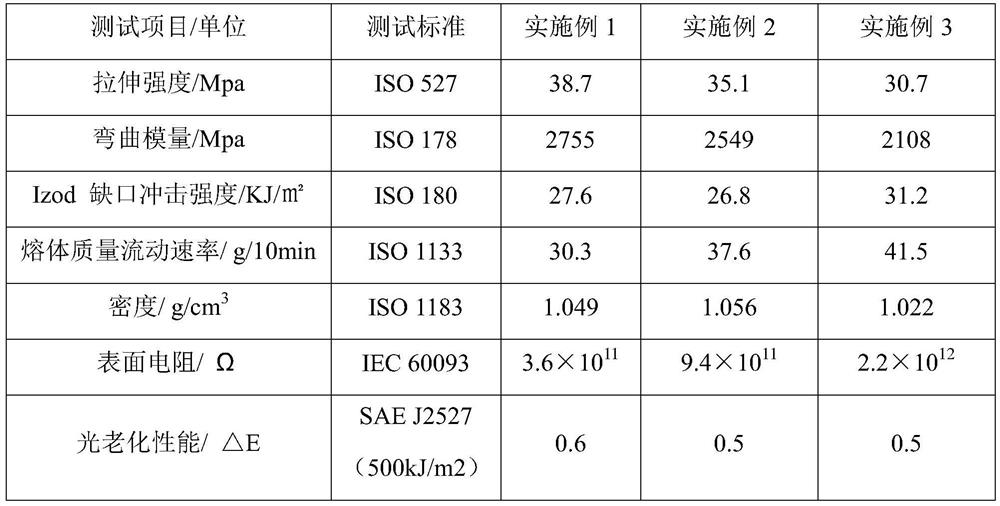

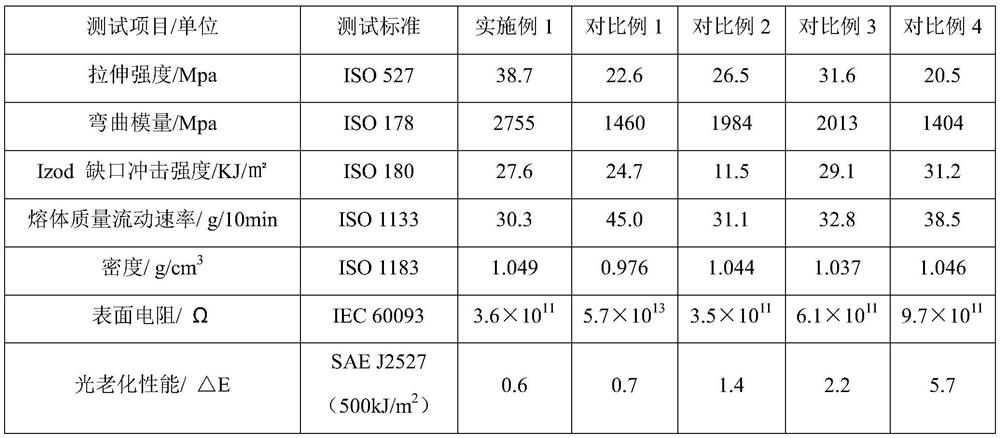

[0024] Add 50 parts of copolymerized polypropylene with a crystallinity of 65-70%, 30 parts of AES plastic, 10 parts of talcum powder, 10 parts of POE-g-MAH, and 0.5 parts of antioxidant into a high-mixer and mix for 15 minutes; The materials are put into the twin-screw extruder, kneaded, extruded, cooled and pelletized to obtain a high-performance automotive exterior resin; the extrusion temperature of each extrusion section in the twin-screw extruder is 190°C and 190°C respectively , 200°C, 210°C, 220°C, 230°C, 230°C, 240°C, 240°C, 240°C. The performance test results are shown in Table 1.

Embodiment 2

[0026] Add 60 parts of copolymerized polypropylene with a crystallinity of 65-70%, 20 parts of AES plastic, 15 parts of talcum powder, 8 parts of POE-g-MAH, and 0.5 parts of antioxidant into a high-mixer and mix for 10 minutes; then mix evenly The materials are put into the twin-screw extruder, kneaded, extruded, cooled and pelletized to obtain a high-performance automotive exterior resin; the extrusion temperature of each extrusion section in the twin-screw extruder is 185°C and 185°C respectively , 195°C, 205°C, 215°C, 225°C, 225°C, 235°C, 235°C, 235°C. The performance test results are shown in Table 1.

Embodiment 3

[0028] Add 70 parts of copolymerized polypropylene with a crystallinity of 65-70%, 10 parts of AES plastics, 15 parts of talc powder, 5 parts of POE-g-MAH, and 0.5 parts of antioxidant into a high-mixer and mix for 5 minutes; then mix evenly The materials are put into the twin-screw extruder, kneaded, extruded, cooled and pelletized to obtain a high-performance automotive exterior resin; the extrusion temperature of each extrusion section in the twin-screw extruder is 180°C and 180°C respectively , 190°C, 200°C, 210°C, 220°C, 220°C, 230°C, 230°C, 230°C. The performance test results are shown in Table 1.

[0029] Table 1

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com