Process for producing sodium hydroxymethyl sulfonate by using byproduct formaldehyde and sodium sulfate

A technology of sodium hydroxymethanesulfonate and by-product sodium sulfate, which is applied in the fields of sulfonate preparation and organic chemistry, and can solve the problems of high calorie and manpower, limited demand for sodium sulfide, and difficulty in marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

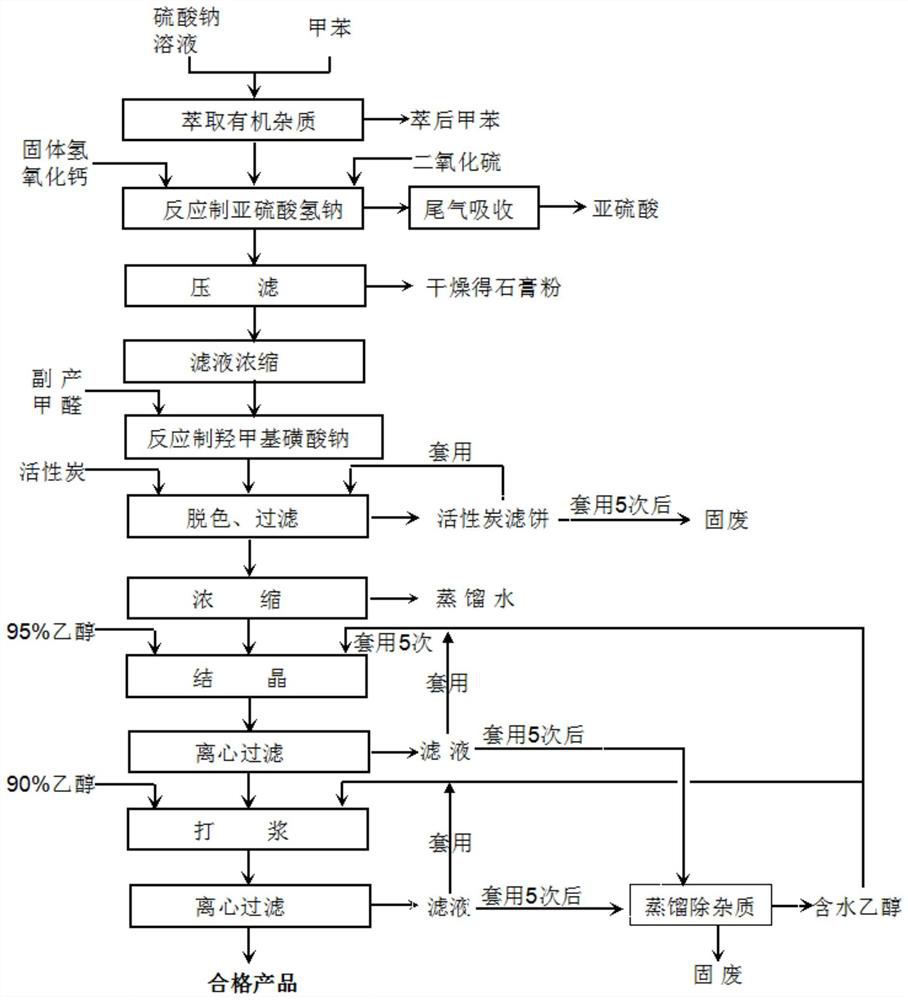

[0035] like figure 1Shown, a kind of technology that utilizes by-product formaldehyde and sodium sulfate to produce sodium hydroxymethanesulfonate, comprises the steps:

[0036] Step 1, 4000kg concentration is that the by-product sodium sulfate solution of 20% is added in the reactor, then adds organic matter in the toluene extraction solution, and the addition of toluene is 500L; The purpose of toluene addition is: remove the by-product sodium sulfate solution Organic impurities to ensure that the color of the product is qualified;

[0037] Step 2, add 487kg technical grade (90%) calcium hydroxide (solid) in the reaction kettle, turn on the forced circulation pump and heat the reaction kettle to 50-55 ℃, pass into sulfur dioxide gas after 30min and carry out spray absorption;

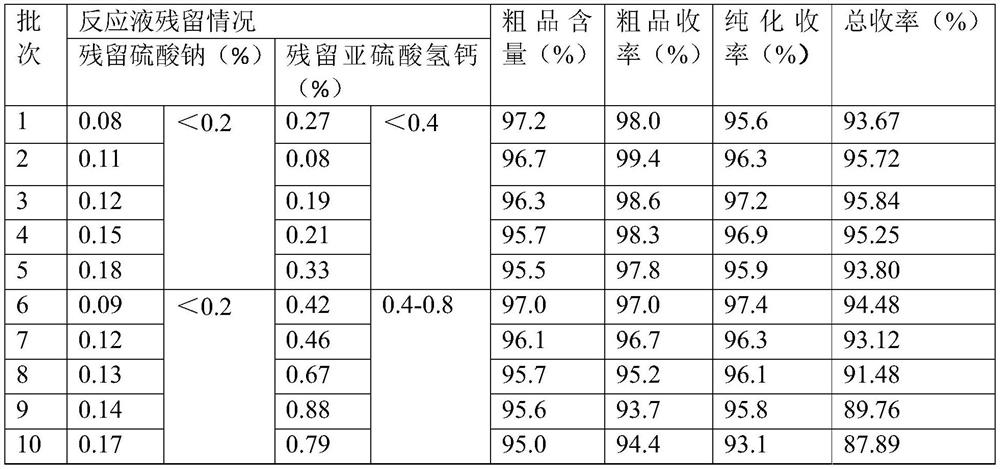

[0038] Step 3. Through on-line sulfate and calcium ion detection, when the sulfate ion concentration is lower than 0.2%, the method of recalling sodium sulfate and (or) introducing sulfur dioxide ensu...

Embodiment 2

[0044] Embodiment 2 Solvent, activated carbon cycle apply mechanically

[0045] Step 1, adding 4000kg of by-product sodium sulfate solution with a concentration of 30% into the reactor, then adding 500L of toluene to extract the organic matter in the solution;

[0046] Step 2, add 731kg technical grade (90%) calcium hydroxide (solid) in the reaction kettle, turn on the forced circulation pump and heat the reaction kettle to 50-55 ℃, pass into sulfur dioxide gas after 30min and carry out jet absorption;

[0047] Step 3: Real-time detection of the sodium sulfate concentration by the online detection system, by adjusting the sodium sulfate and feeding the sulfur dioxide to ensure that the sodium sulfate concentration is less than 0.2% and the calcium ion concentration is less than 0.4%, and then the reaction solution is transferred to the plate and frame filter press The solid-liquid separation is carried out in the machine, the filtrate is sucked into the concentration kettle by...

Embodiment 3

[0053] The mechanical application of embodiment 3 sulfurous acid

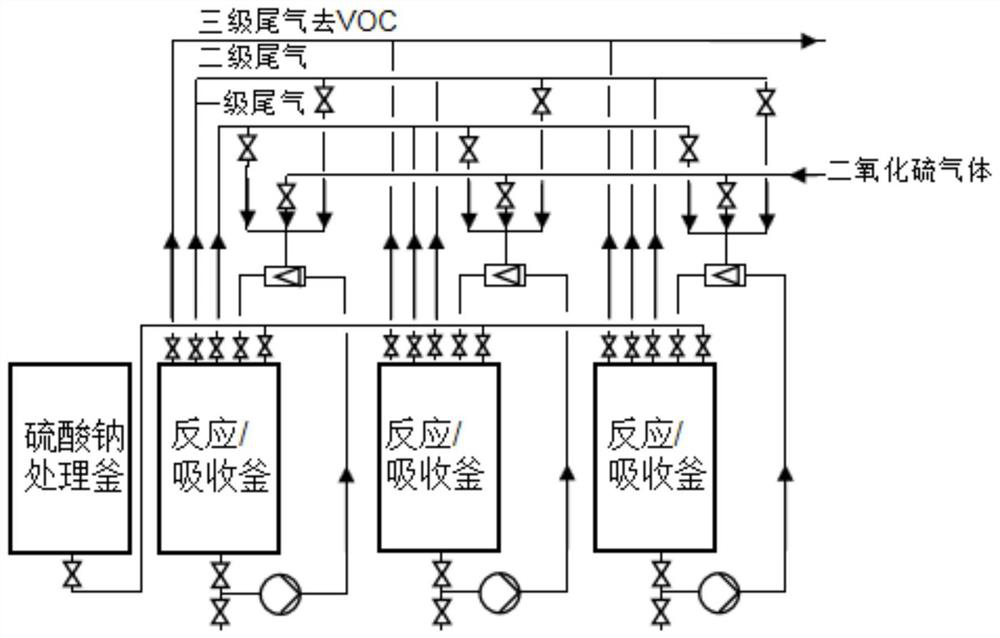

[0054] combine figure 2 As shown, step 1, 4000kg concentration is that the by-product sodium sulfate solution of 20% is added in the reactor, then adds organic matter in the toluene extraction solution, the addition of toluene is 500L, then transfers into (secondary or three) by pump grade) in the sulfur dioxide tail gas absorption kettle;

[0055] Step 2, add 487kg industrial grade (90%) calcium hydroxide (solid) to the (second or third) sulfur dioxide tail gas absorption kettle, turn on the forced circulation pump and heat it to 50-55 ° C, spray and absorb the overflowing sulfur dioxide gas of the upper stage ;

[0056] Step 3: When the reaction in the upper-level reactor is complete, the reaction solution is processed and the materials (sodium sulfate solution, solid calcium hydroxide) are added again, and the tail gas is absorbed as a three-level absorption tank. Sulfur dioxide gas is introduced into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com