Starting device for vertical axis wind turbine (VAWT)

A technology of wind generators and starting devices, which is applied in the direction of wind generator components, wind motors, wind motor combinations, etc., which can solve the problems of unsatisfactory low-speed start-up performance of generators, low wind energy utilization efficiency, and poor self-starting performance, etc., to achieve Optimize self-starting performance, improve wind energy utilization efficiency, and facilitate maintenance and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

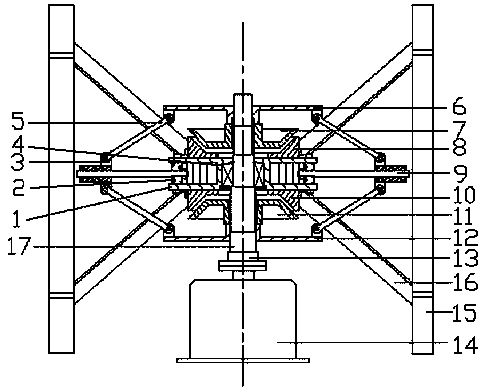

[0029] see figure 1 , a starting device for a vertical-axis wind-driven generator, comprising a wind rotor main shaft 17 and a wind rotor, the wind rotor main shaft 17 is coaxially fixedly connected to the generator main shaft 14 through a coupling 13, and the wind wheel drives the wind rotor main shaft 17 to rotate, so that the generator Start, the wind rotor includes at least two generator blades 15, and evenly distributed around the wind rotor main shaft 17, the generator blades 15 are fixedly connected with the outer end of the blade support plate 16, when the generator blade 15 rotates, the blade support plate 16 The inner end transmits torque to the wind rotor main shaft 17, and then drives the wind rotor main shaft 17 to rotate. It is characterized in that: the inner end of the blade support plate 16 is fixed on the empty bearing seat 1, and the empty sleeve bearing seat 1 is installed through at least one bearing 4 On the wind wheel main shaft 17, the empty sleeve bea...

Embodiment 2

[0038] The technical solution of this embodiment is basically the same as that of Embodiment 1, especially in that:

[0039] In this embodiment, the connection between the outer friction discs 7, 11 and the wind wheel main shaft 17 is a spline. The splines have good guidance, can realize the dynamic connection between the mutually matched external friction discs 7, 11 and the wind wheel main shaft 17, and have the advantages of small stress concentration and strong load bearing capacity.

Embodiment 3

[0041] The technical solution of this embodiment is basically the same as that of Embodiment 1, especially in that:

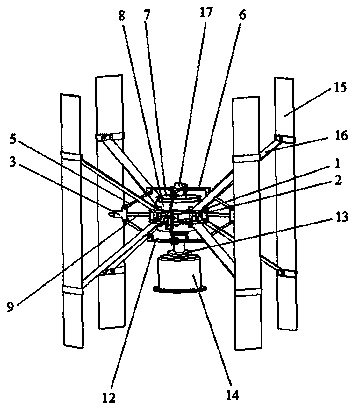

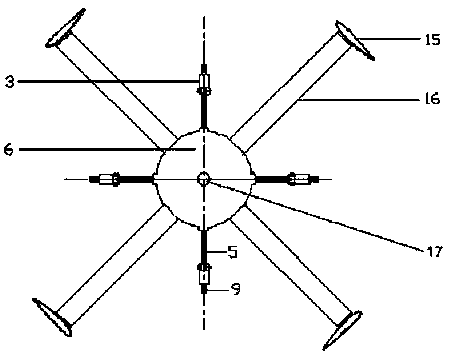

[0042] In this example, see figure 2 and image 3 , In the present embodiment, there are 4 generator blades 15, and the slider mechanism of the pressing mechanism also includes 4 groups. Four generator blades 15 and four sets of slider mechanisms are used to form a vertical-axis wind turbine starting device, so that the device can capture wind energy as much as possible and at the same time optimize the structure of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com