Oxygen-making and nitrogen-making air compressor

A technology for air compressors and main engines, which is applied in mechanical equipment, machines/engines, liquid variable capacity machines, etc. It can solve the problems of increased suction resistance, poor air permeability, and high maintenance costs, and achieves increased service life and suction resistance. Low, low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

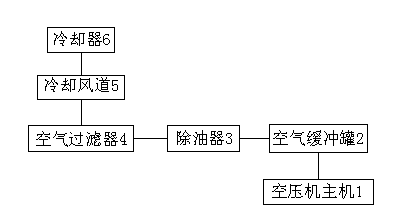

[0011] refer to figure 1 , the specific embodiment adopts the following technical scheme: it comprises air compressor host 1, air buffer tank 2, degreaser 3, air filter 4, cooling air channel 5 and cooler 6, air compressor host 1, air buffer The tank 2, the degreaser 3, and the air filter 4 are connected in sequence, and the air filter 4 is connected to the cooler 6 through the cooling air duct 5.

[0012] The air filter 4 is filtered by an air filter element with a nano-surface layer, and the dust will be intercepted on the surface without blocking the inside of the filter element.

[0013] The degreaser 3 adopts a two-stage oil-fine separation core, which further enhances the effect of oil-fine separation.

[0014] The beneficial effects of this specific embodiment are: the filter element has low suction resistance and low energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com