Bearing lubricating structure of reduction box

A bearing lubrication and reduction box technology, applied in gear lubrication/cooling, elevators in buildings, transportation and packaging, etc., can solve problems such as high cost, noise, and reduced bearing life, reduce maintenance workload, structural design Simple, vibration-damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

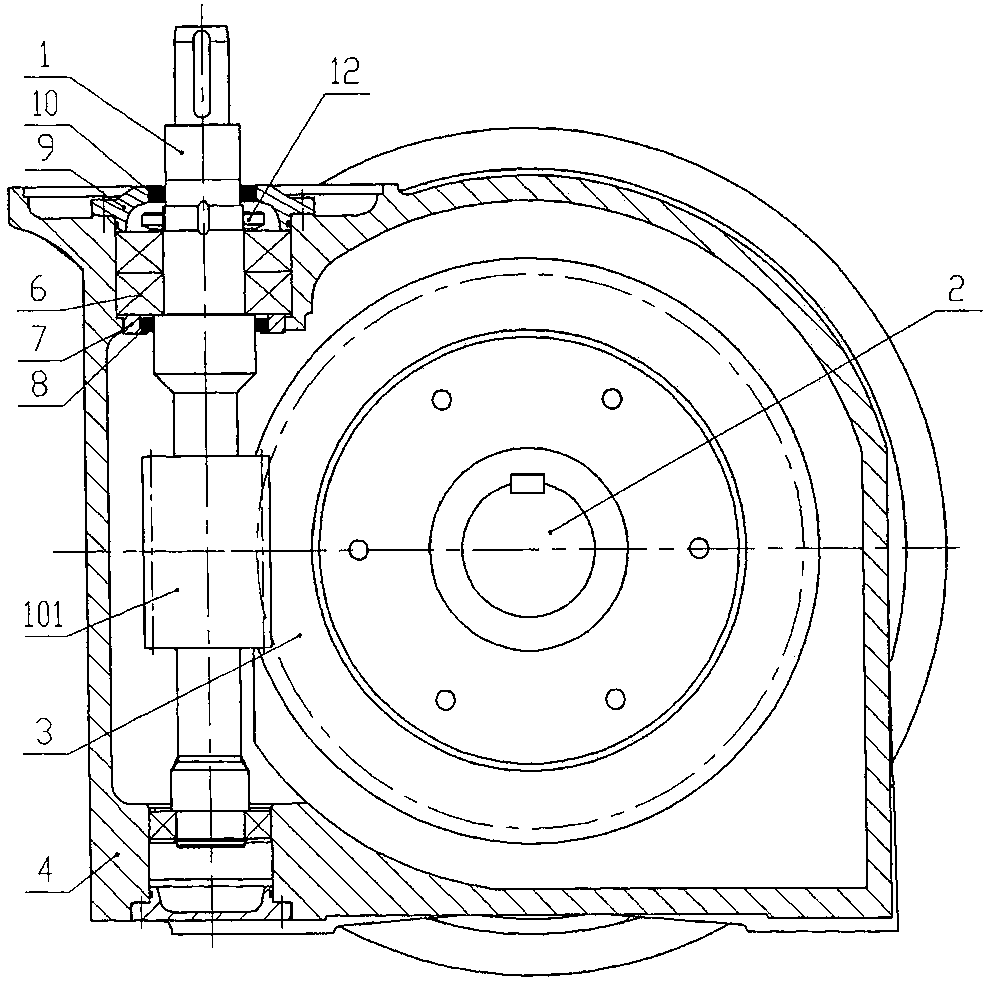

Embodiment 1

[0025] see figure 2 , in an embodiment of the present invention, the described reduction box is the worm gear box of the elevator traction machine, the described driving shaft is the worm shaft, and the worm shaft is installed vertically, specifically: the described reduction box includes a worm screw Shaft 1, main shaft 2, worm wheel 3, box body 4, both ends of the worm shaft 1 are rotatably placed on the box body 4 through rolling bearings, and one end of the worm shaft 1 extends to the outside of the box body 4 and the motor (not shown in the figure) connected. The main shaft 2 is a driven shaft, which is pivoted on the box body 4, and a worm wheel 3 is sleeved in the middle of the main shaft 2. There is a bushing 5 at the step above the threaded section 101 of the worm shaft 1, and the inner side of the lower end face of the bearing 6 installed above the threaded section 101 of the worm shaft 1 is pressed against the bushing 5, and the outer side of the lower end face ...

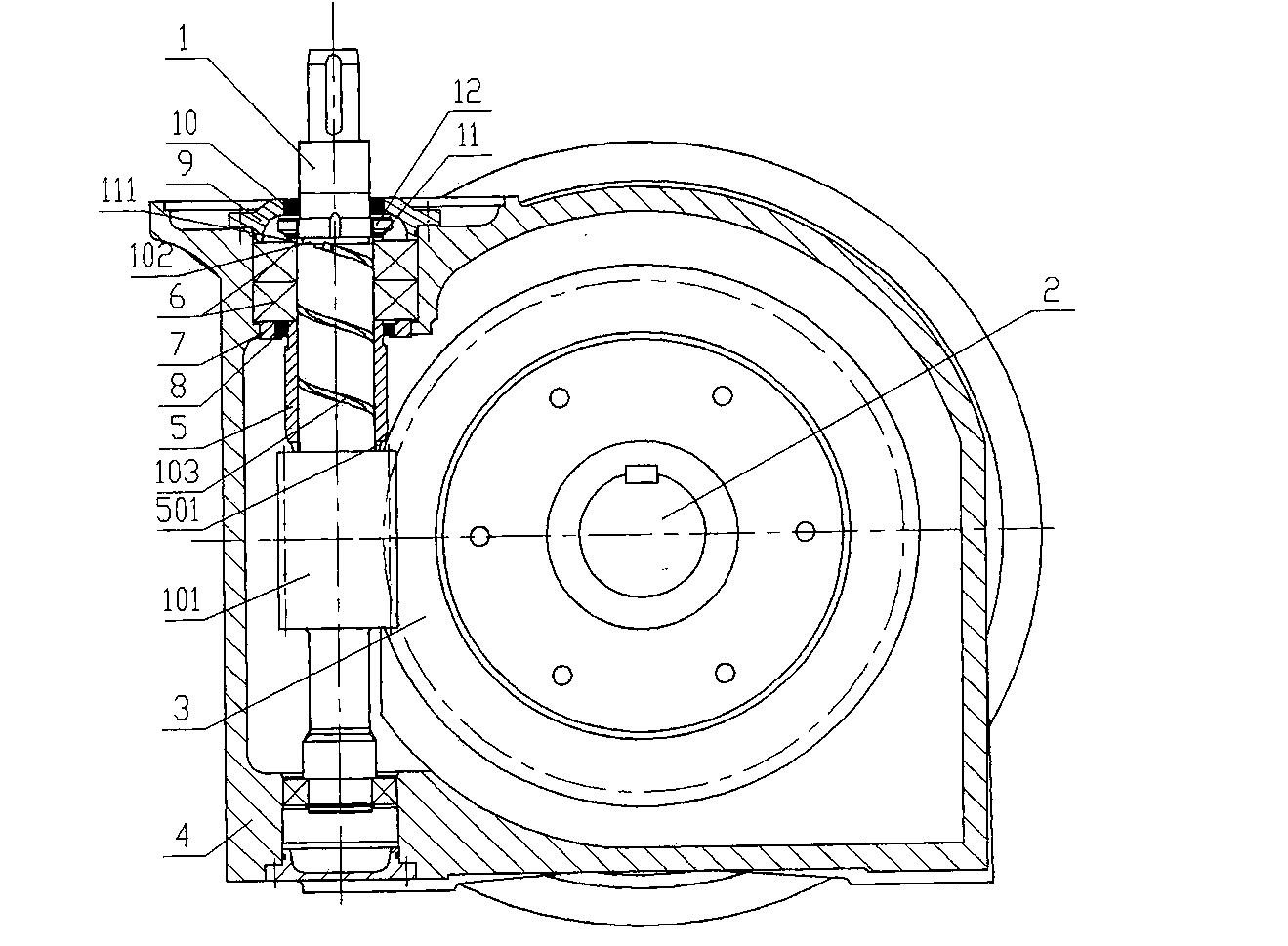

Embodiment 2

[0027] see image 3 , in another embodiment of the present invention, the described reduction box is the worm gear box of the elevator traction machine, the described driving shaft is the worm shaft, the worm shaft is installed vertically, and the reduction box includes the worm shaft 1, the main shaft 2. Worm wheel 3, box 4, both ends of the worm shaft 1 are rotatably placed on the box 4 through rolling bearings, and one end of the worm shaft 1 extends out of the box 4 and is connected to the motor (not shown in the figure). The main shaft 2 is a driven shaft, which is pivoted on the box body 4, and a worm wheel 3 is sleeved in the middle of the main shaft 2. There is a bushing 5 at the step above the threaded section 101 of the worm shaft 1. The inner side of the lower end face of the bearing 6 installed on the upper part of the worm shaft 1 is pressed against the bushing 5, and the outer side of the lower end face of the bearing 6 is pressed against the oil seal seat. 7,...

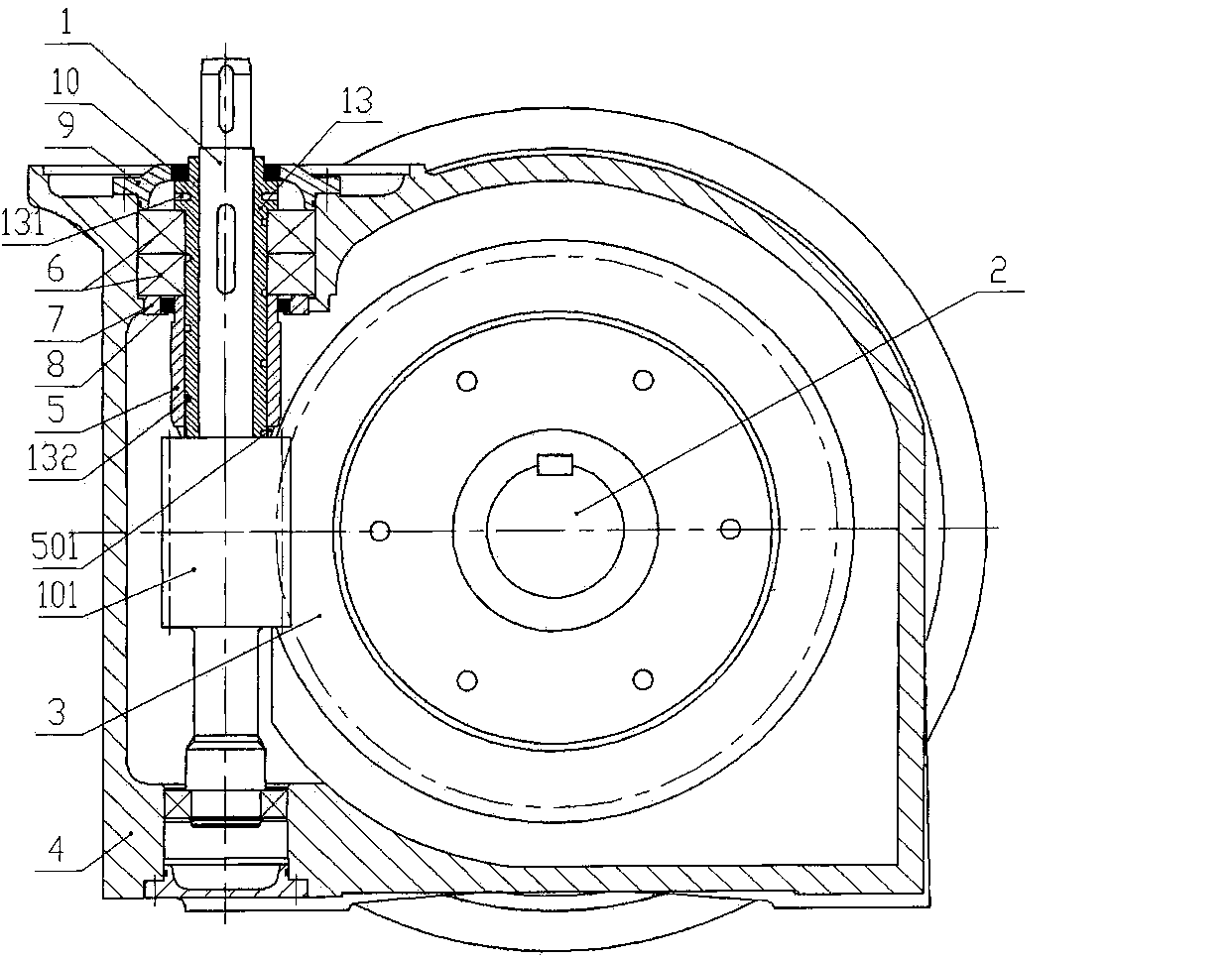

Embodiment 3

[0029] see Figure 4 , in another embodiment of the present invention, the described reduction box is the worm gear box of the elevator traction machine, the described driving shaft is the worm shaft, the worm shaft is installed vertically, and the reduction box includes the worm shaft 1, the main shaft 2. Worm wheel 3, box 4, both ends of the worm shaft 1 are rotated on the box 4 through rolling bearings, and one end of the worm shaft 1 extends out of the box 4 and is connected to the motor (not shown in the figure). The main shaft 2 is a driven shaft, which is pivoted on the box body 4, and a worm wheel 3 is sleeved in the middle of the main shaft 2. There is a journal 104 with a smaller diameter between the worm shaft section with the bearing 6 and the threaded section 101, so a second shaft sleeve 14 is sleeved on the journal 104, and the second shaft sleeve 14 is a threaded sleeve. One end is pressed against the stepped surface of the threaded section 101, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com