Outer barrel of centrifugal drying machine with sealing flange

A drying machine with sealing technology, which is applied in the direction of dryers, drying chambers/containers, electrical components, etc., can solve the problems of affecting the sealing effect and the high purchase price of the shape of the sealing tape, so as to reduce the purchase cost, quickly replace and realize The effect of seamless sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

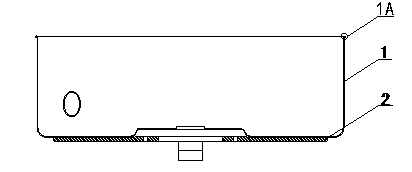

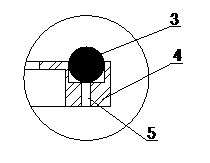

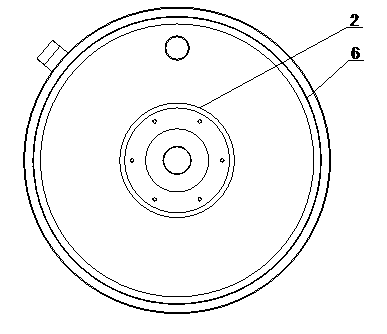

[0014] Such as Figure 1-3 As shown, the outer cylinder of the drying machine with a sealing flange according to the embodiment of the present invention includes an outer cylinder body 1 and an outer tub bottom 2, and the outer cylinder body 1 and the outer tub bottom 2 are cooperatively connected by a welding ring 6, A flange ring 4 is added to the upper end of the outer cylinder body 1, and a sealing groove is arranged on the ring surface of the flange ring 4, and an O-shaped rubber sealing ring 3 is correspondingly installed in the groove; at the same time, a hole diameter of The 1mm easy-to-disassemble hole 5 has a sealing groove width of 4mm and a depth of 2.5mm.

[0015] The above embodiment is one of the more preferred specific implementations of the present invention, and common changes and substitutions made by those skilled in the art within the scope of the technical solution shall be included in the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com