Redundancy device for aircraft electric brake pressure sensor and method for controlling redundancy device

A pressure sensor and redundant device technology, applied in measuring devices, instruments, force/torque/work measuring instruments, etc., can solve the problem of low reliability of pressure sensors, and achieve the effects of convenient maintenance, improved accuracy, and reduced errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

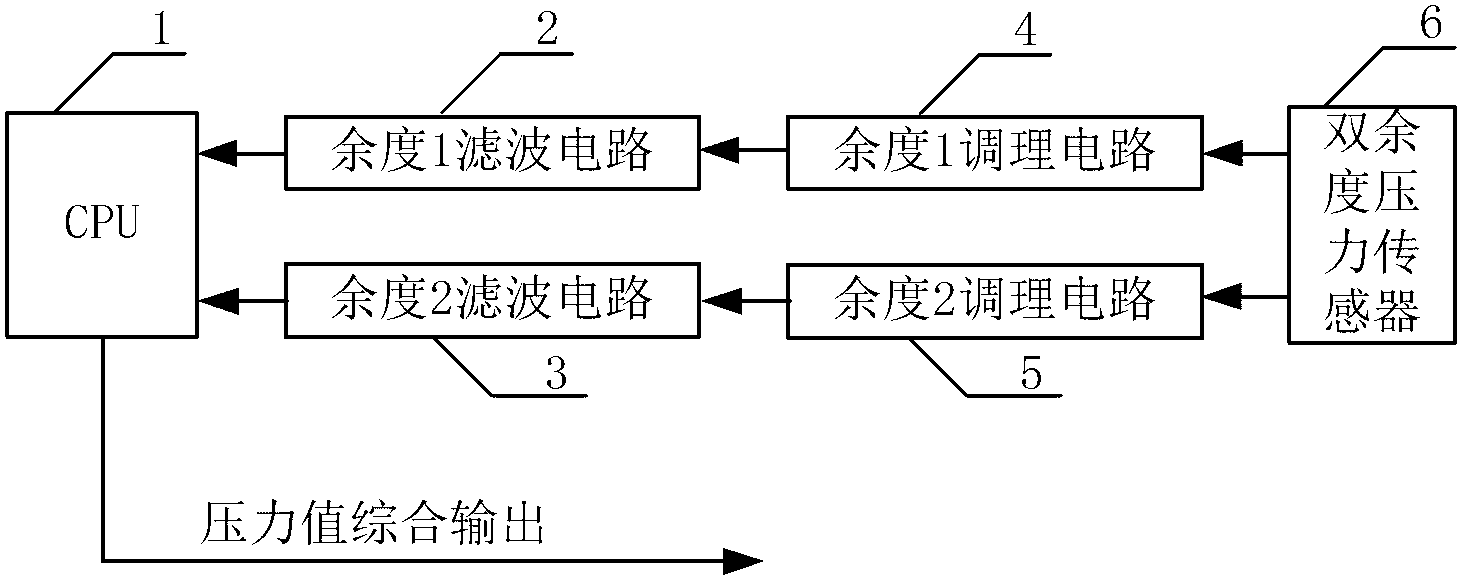

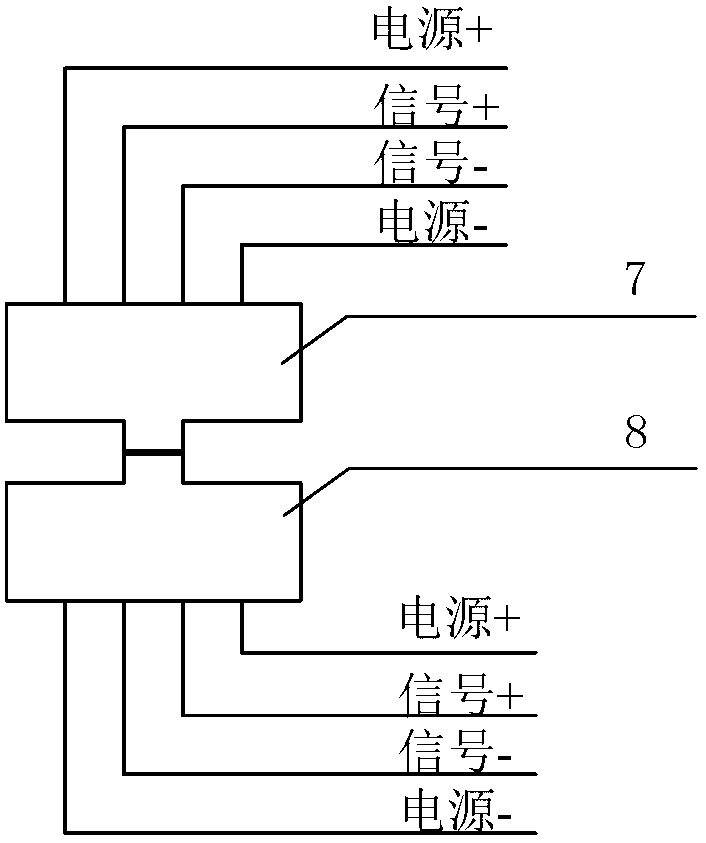

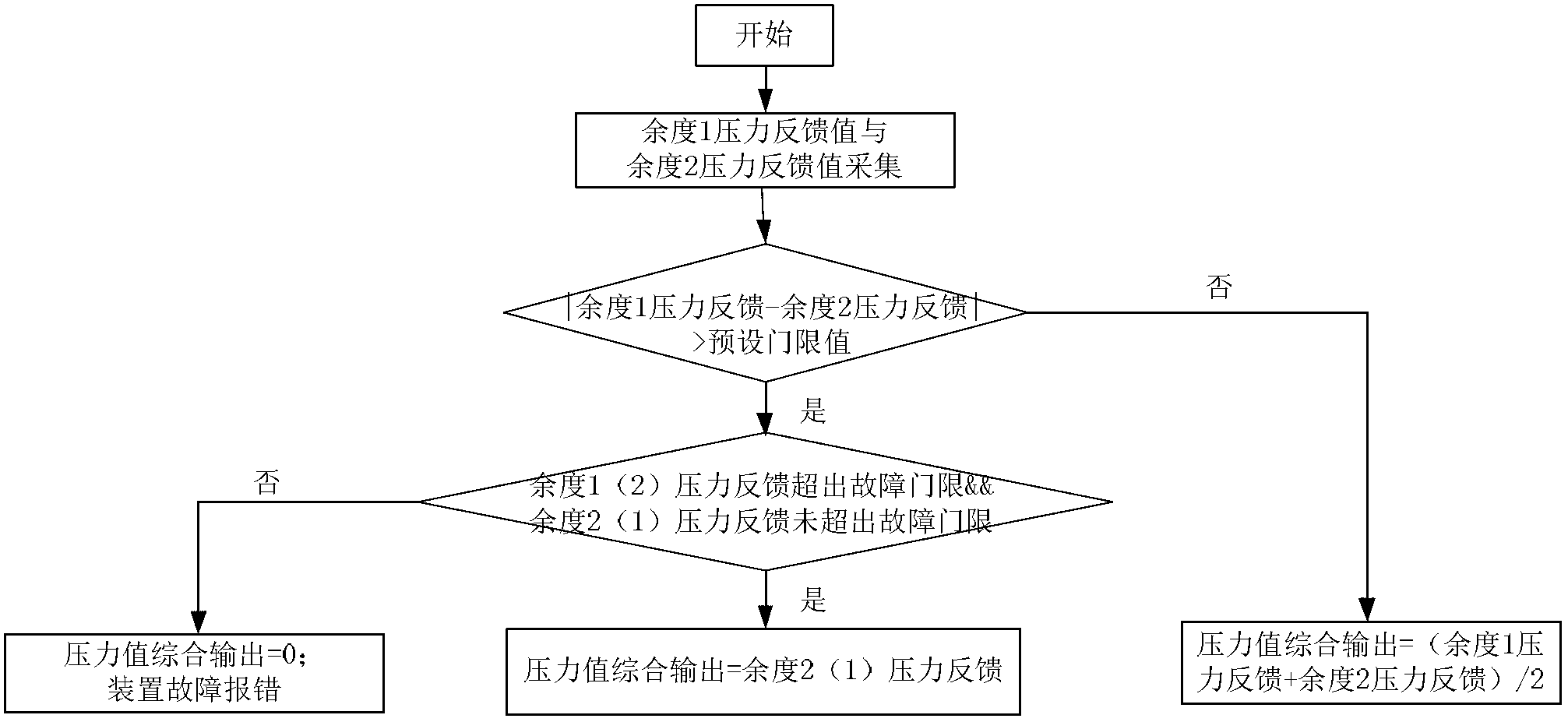

[0016] The redundant device and management method of the aircraft electric brake pressure sensor is based on the theory of the original pressure sensor system, and at the same time, the double redundant high-performance pressure sensor is selected, and the double redundant pressure acquisition and signal processing method is developed. device. The redundant device can work with high efficiency at the same time, and it can also automatically cut off the fault margin when the single redundancy unit fails, and the other normal redundancy pressure sensor provides pressure signal collection and processing. This invention not only ensures the normal operation of the aircraft electric brake pressure sensor system, improves the accuracy of pressure signal acquisition and processing, but also provides a solution in the event of a sudden failure of the system, so that it will not be damaged due to electrical signal transmission. During the process or the accidental failure of power elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com