Organic light-emitting diode display panel and manufacturing method thereof

A technology for light-emitting diodes and display panels, which is used in electroluminescence light sources, semiconductor/solid-state device manufacturing, light sources, etc., can solve the problems of the influence of the display panel yield on the positioning accuracy, the complex production process, and the high production cost, and save masking. The effect of diaphragm alignment process, simplifying production process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

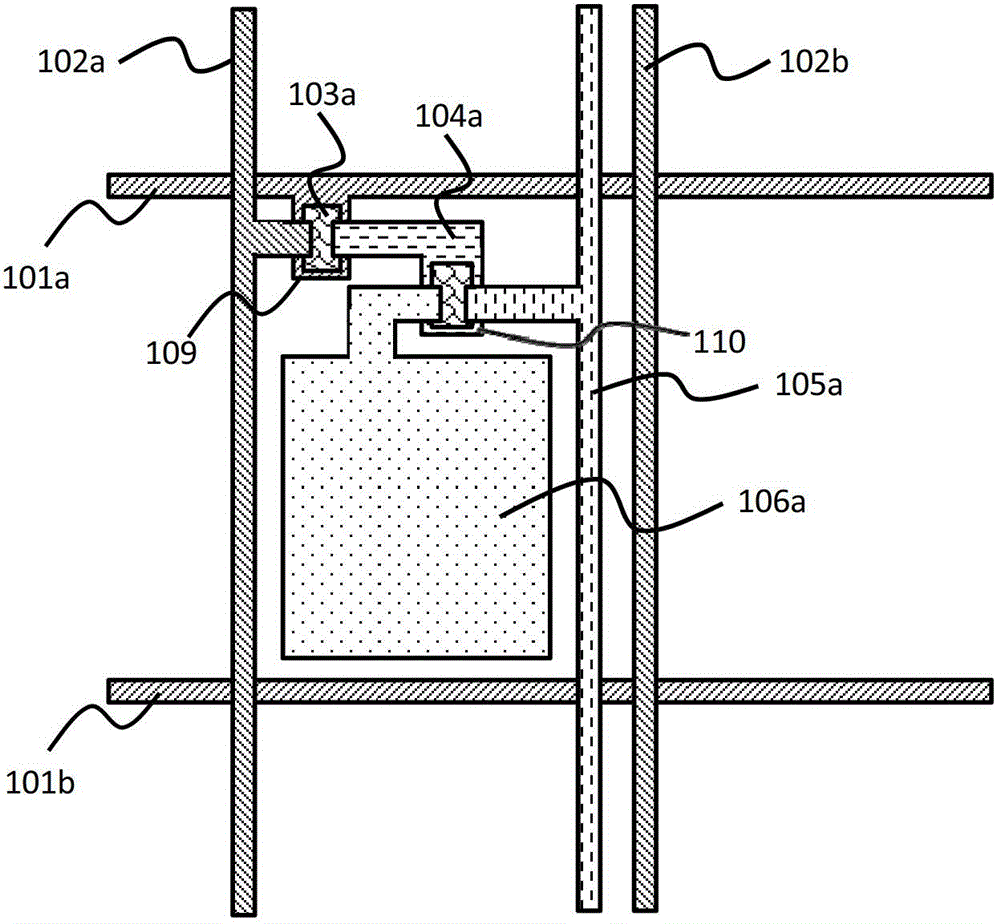

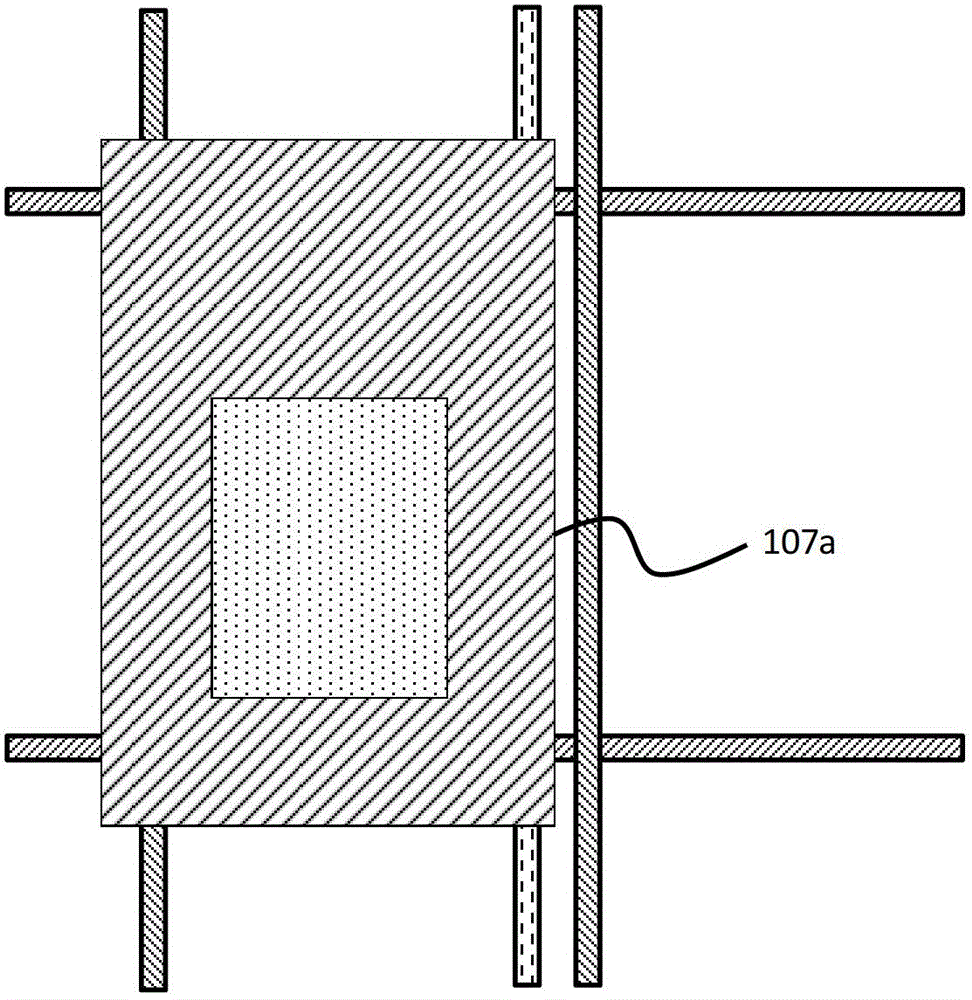

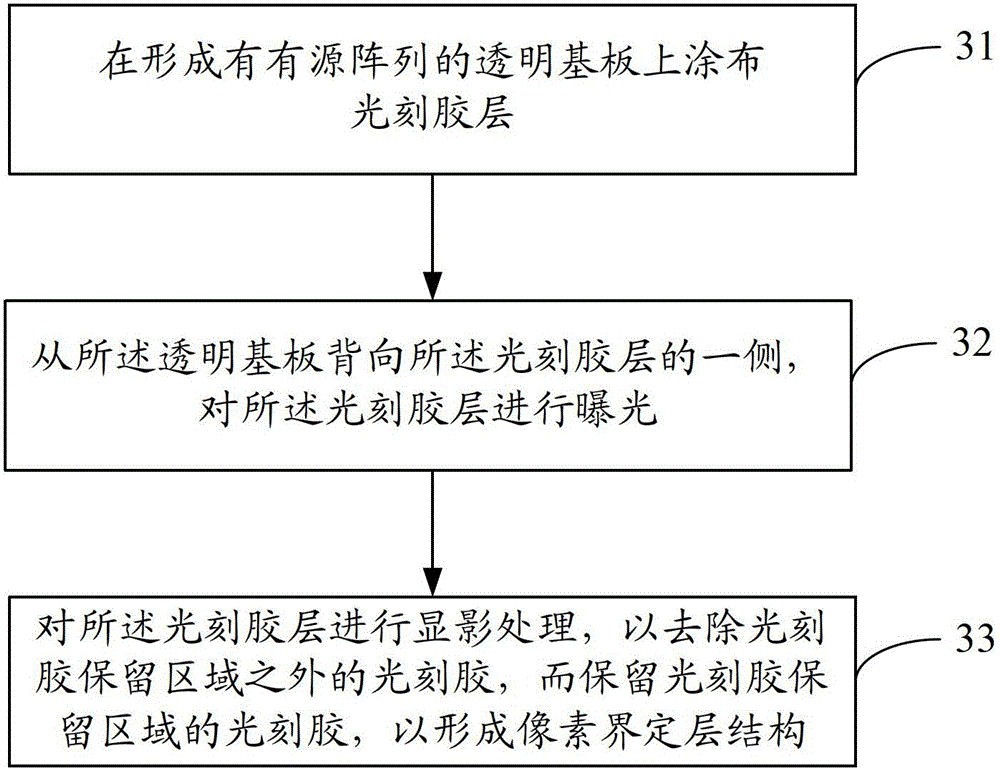

[0044] The method for manufacturing the pixel-defining layer of an OLED display panel provided by the embodiment of the present invention does not require a special mask, and does not require an alignment process during the photolithography process, thereby reducing production costs, simplifying the production process, and Improve product yield. In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0045] The pixel defining layer of the OLED display panel in the embodiment of the present invention is prepared after the active array and the anode of the pixel are prepared, and before the formation of the organic light emitting layer.

[0046] The traditional pixel definition layer usually uses a specially designed mask to pattern the pixel definition layer. The embodiment of the present invention does not req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com