Manual multifunctional wire tightening device and a wire tightening method

A multi-functional, wire-tightening technology, applied to overhead lines/cable equipment, etc., can solve the problems of high risk factor, high cost, inconvenient operation, etc., and achieve the effect of safe and reliable construction, flexible construction and transportation, and reduced rotational force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

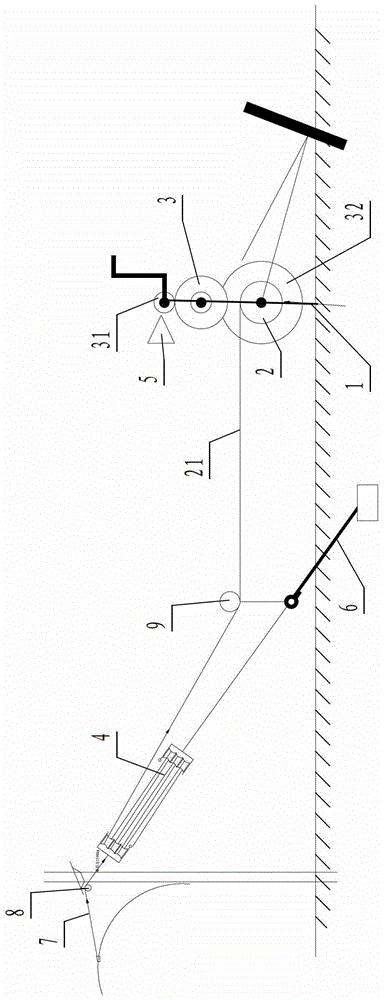

[0030] a kind of like figure 1 The shown manual multi-function tightening device includes a frame 1, a rope reel 2, a gear transmission 3 and a pulley block 4. The rope reel is rotatably supported on the frame, and the rope reel and the gear transmission group Transmission connection, the gear shift is a speed-up gear set, the final gear 32 in the gear shift set is coaxial with the rope reel to drive the rope reel to rotate, and the first stage gear 31 in the gear shift set is manually controlled by the handle. Drive, the anti-reverse device 5 that is used to prevent the reverse rotation of the gear is also provided on the multi-function tensioning device, the traction rope 21 on the rope reel will be wound on the pulley block when working, and one end of the pulley block is fixed on the backguy during work. On the pile anchor 6, the other end of the pulley block is then connected with the stay rope 7, and the other end of the stay rope walks around the fixed pulley 8 for tran...

Embodiment 2

[0033] A wire tightening method, (1) select a flat ground near the wire tightening tower, lay down a fixed pile, install a multifunctional wire tightening device, and make the rope reel of the wire tightening device perpendicular to the pulling rope;

[0034] (2) After connecting both sides of the frame of the multifunctional wire tightening device with a shackle and a wire rope, fix the wire rope to the fixed pile.

[0035] (3) Pull out the traction rope on the rope reel and wind it around the pulley block according to the required traction force:

[0036] (4) In front of the rope reel, install the fixed pulley for bypassing the traction rope by using the anchor of the guy pile of the line tension rod;

[0037] (5) Suspend the fixed pulley for transition on the tower on the side of the wire to be pulled;

[0038] (6) Hang one end of the "pulley block" wrapped around the traction rope on the guy pile anchor of the line tower;

[0039] (7) Clamp the "wire clamp" to the wire t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com