Method for making plug-pull high voltage terminal

A production method and terminal head technology, applied in the direction of cable terminals, etc., can solve the problems of many hidden dangers, cracking of cold shrinkable tubes, economic losses of enterprises, etc., to prevent uneven distribution of electromagnetic fields, prevent insulation breakdown, and prevent economical effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

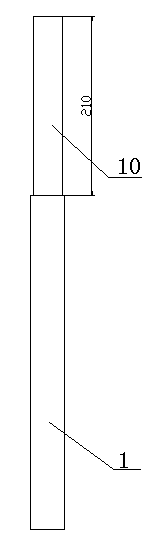

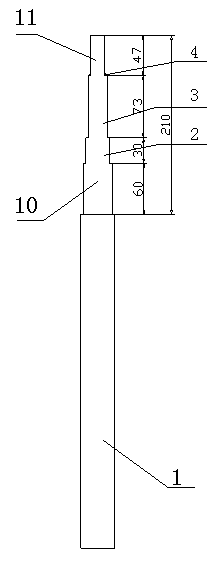

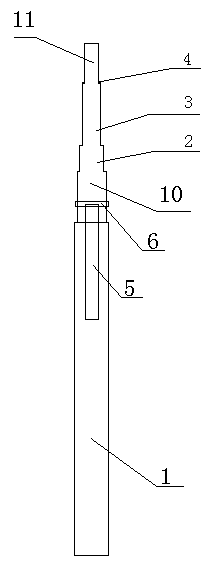

[0016] The present invention takes the plug-in terminal CBN-35 series as an example, which is mainly reflected in the proper solution to the problem of electric field concentration at the cut-off of the outer shield during the terminal manufacturing process, and effectively prevents the uneven distribution of the electromagnetic field of the semiconductor outer shield from insulation breakdown Phenomenon. The meaning of the so-called plug-in terminal can be defined as "plug", and its terminal "socket" has been installed in the cabinet before entering the site. The plug-in terminal is made of silicone rubber, and there is a stress cone inside, which properly solves the weak link of the stripped section of the semiconductor and copper shielding layer in the cable, and effectively prevents the occurrence of insulation breakdown. There is a metal shell outside the plug-in terminal to connect and ground the electrical equipment, so that the equipment can be fully insulated, fully s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com