A bridge head structure used to control bridge head jumping

A technology of pavement structure and abutment, which is applied to bridges, bridge parts, bridge construction, etc. It can solve problems such as bridge structure being easily damaged, driving discomfort, damage, etc., achieve good effect of preventing settlement, overcome complex force, The effect of overcoming the weak link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

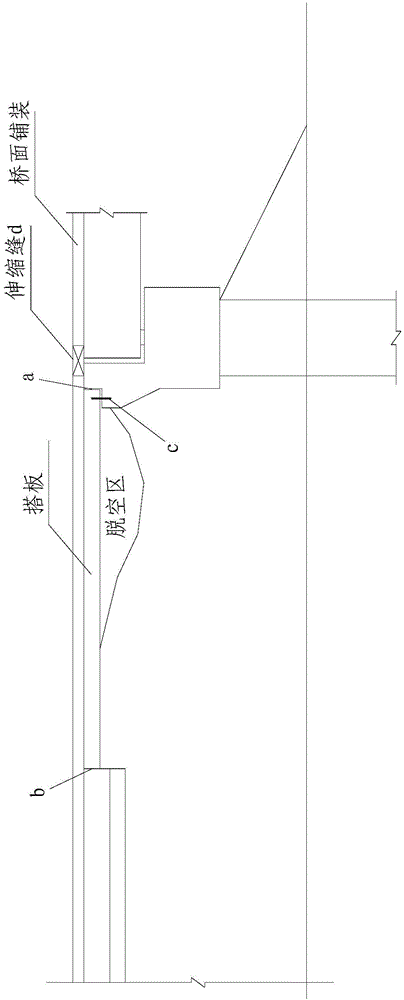

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

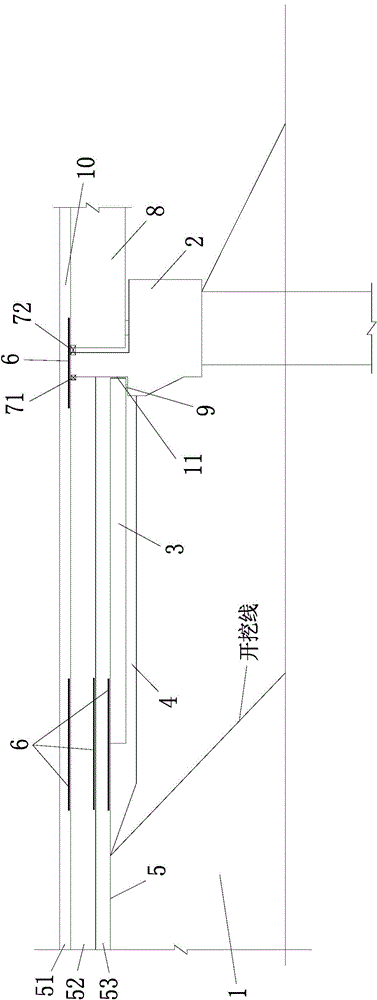

[0038] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] Such as figure 2 As shown, a bridge head structure for controlling bridge head jumping, including abutment 2, beam slab 8, subgrade 1, pavement structure layer 5, bridge head board 3 and bridge deck pavement layer 10, pavement structure layer 5 from the bottom The upper part includes subbase 53, base 52 and surface course 51; the bridge head 3 is arranged between the subgrade 1 and the subbase 53, and one end thereof is erected on the abutment 2 corbel; the bridge head 3 is provided with a cushion 4 Condensation joints 71 are provided between the base layer 52 and the back of the abutment 2, expansion joints 72 that can stop water are provided between the back of the abutment 2 and the beam slab 8, and the surface layer 51 is integrally connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com