Penning anion source ceramic neutron tube

A technology of negative ion source and neutron tube, applied in the direction of DC voltage accelerator, etc., can solve the problems of short life and low output of neutron tube, and achieve the effect of improving life.

Inactive Publication Date: 2012-10-03

NORTHEAST NORMAL UNIVERSITY

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These factors are the main reasons for the low output and short life of neutron tubes in my country.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

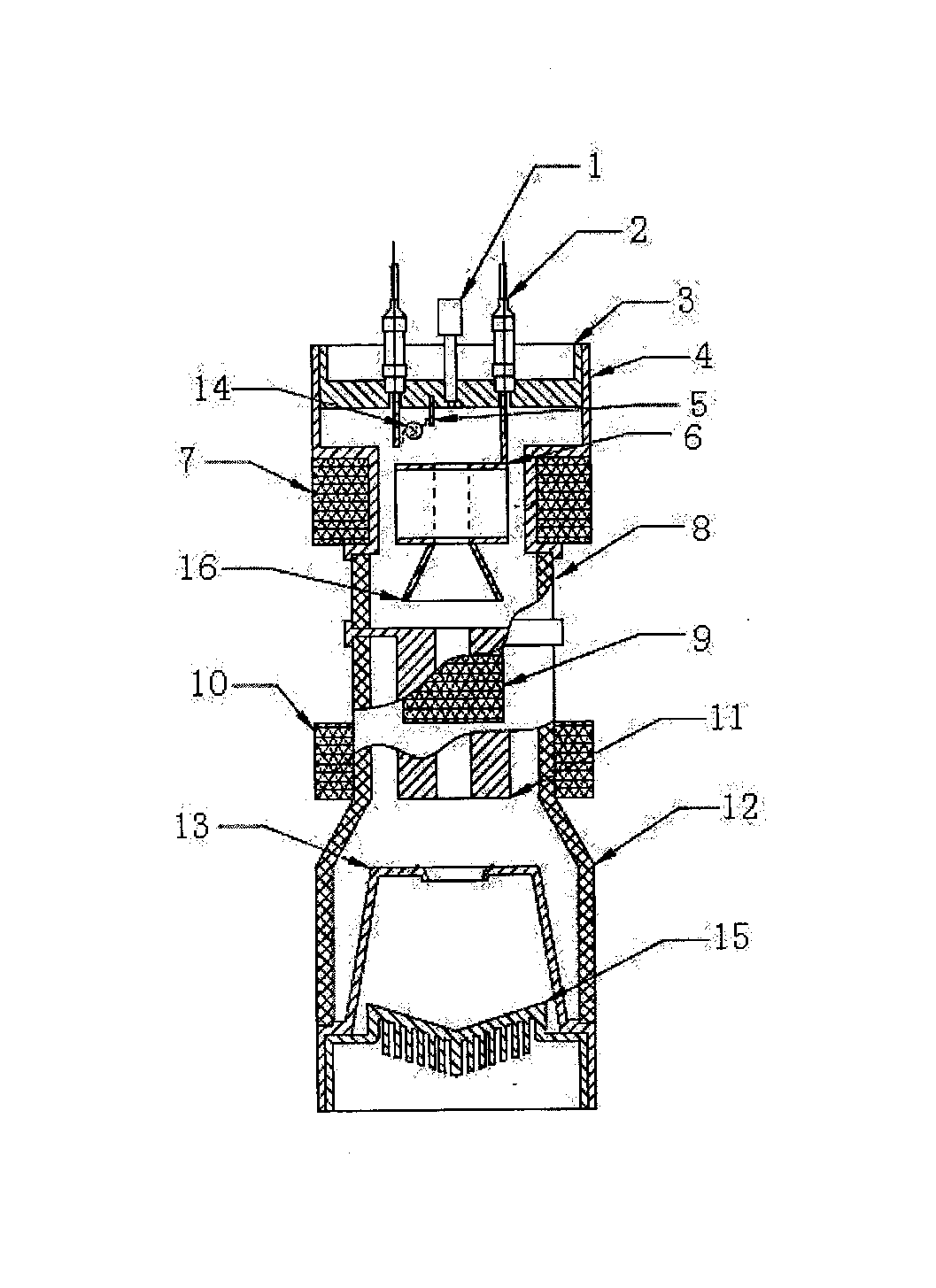

The invention belongs to an improved turn-off neutron source and in particular relates to a Penning anion source ceramic neutron tube. The Penning anion source ceramic neutron tube adopts a PIG type anion source to generate anions of deuterium (D) and tritium (T). The anion source adopts a lateral lead-out or eccentric lead-out mode; positive high voltage is added on a target; and under the condition of removing electrons from lead-out beams, the lead-out beams are monatomic anions and the utilization ratio of the beams generating neutrons can reach 100 percent. The neutron yield of the neutron tube with the structure is increased by about 2 orders of magnitude compared with that of the former neutron tube under the conditions of the same high voltage and beams. A tube of phi 50 is taken as an example, the life of the improved Penning anion source ceramic neutron tube is prolonged by more than 10 times, the yield is increased by about 100 times, the stability is not more than 3 percent and the rate of the finished products is more than 90 percent.

Description

technical field [0001] The invention belongs to an improved neutron source that can be shut off, and in particular relates to a ceramic neutron tube of a Penning negative ion source. [0002] Background technique [0002] At present, the neutron tubes produced in China all use the Penning (PIG) ion source that extracts positive ions, and a negative high voltage of -60KV ~ -120KV is added to the target end to reduce the deuterium (D) ions and tritium (T) ions generated by the ion source. accelerated, and a nuclear reaction occurs on the target to produce neutrons. When the ion beam is accelerated, field emission points of electrons are easily formed on the surface of the Faraday cylinder surrounding the target. Some of these electrons hit the ceramic wall, resulting in a decrease in the insulation performance of the ceramic shell. Some hit the ground electrode of the acceleration gap, forming a dark current, which has an adverse effect on the high-voltage power supply. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05H3/06

Inventor 乔双

Owner NORTHEAST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com