Composite supporting roll for hot-continuous rolling wide-strip-steel four-roll mill

A composite support, four-high rolling mill technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of roll peeling and uneven wear of rolls, reduce roll consumption, eliminate stress concentration between rolls, improve The effect of shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

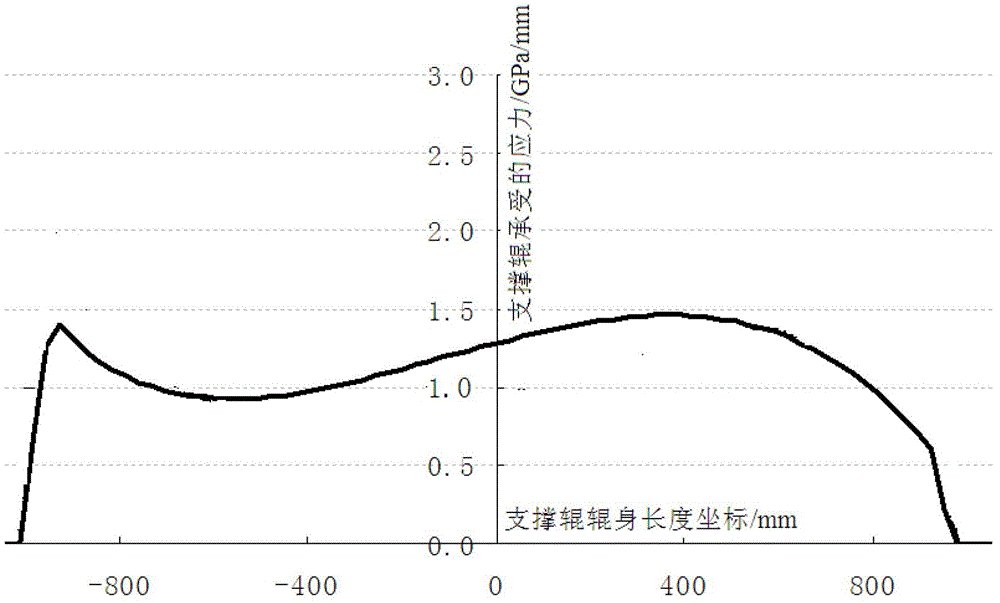

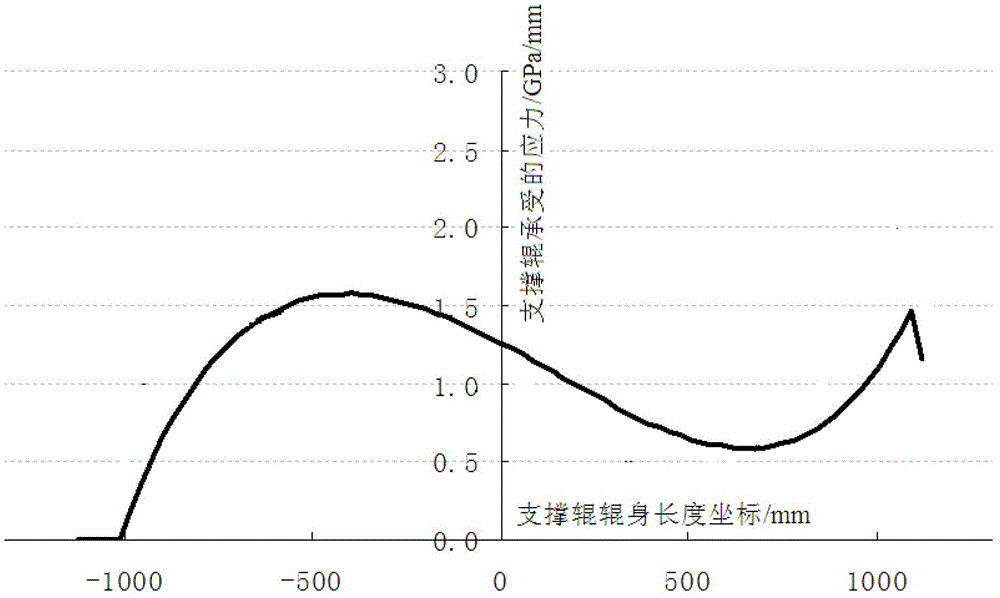

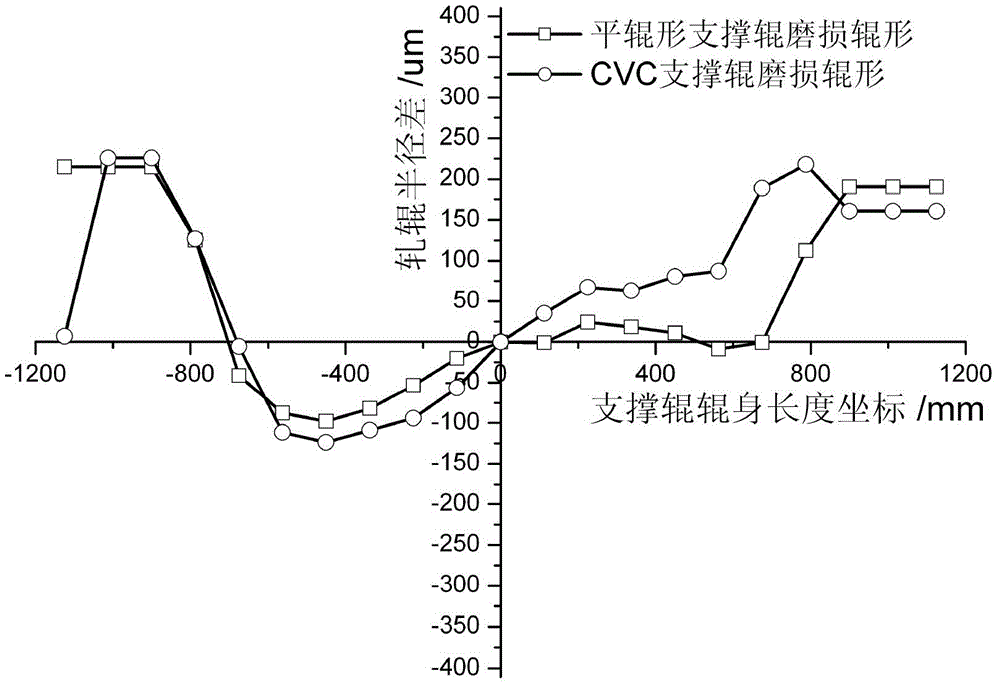

[0030] The curve description equation of the roll shape of the composite back-up roll for the hot continuous rolling wide strip four-roll mill provided by the present invention is as follows:

[0031] R(x)=b 6 x 6 +b 5 x 5 +b 4 x 4 +b 3 x 3 +b 2 x 2 +b 1 x+b 0

[0032] in,

[0033] 0≤x≤2250;

[0034] -4.5×10 -19 ≤b 6 ≤-2.7×10 -19 ,

[0035] 1.8×10 -15 ≤b 5 ≤3.0×10 -15 ,

[0036] -8.2×10 -12 ≤b 4 ≤-5.0×10 -12 ,

[0037] 7.7×10 -9 ≤b 3 ≤1.3×10 -8 ,

[0038] -1.1×10 -5 ≤b 2 ≤-7.3×10 -6 ,

[0039] -4.5×10 -19 ≤b 1 ≤-2.7×10 -19 ,

[0040] -3.5×10 -10 ≤b 0 ≤-4.6×10 -10 ;

[0041] R(x)—work roll body radius difference, mm,

[0042] x—the axial coordinates of the roll body, the origin of the coordinates is on the roll operating side, mm,

[0043] b 6 , b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com