Deep hole machine tool suitable for tapered deep hole boring

A deep hole and tapered technology, which is applied in the field of processing tapered hole devices, can solve the problems of small hole diameter and inability to adapt to the hole, and achieve the effects of improving processing accuracy, preventing processing quality problems, and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

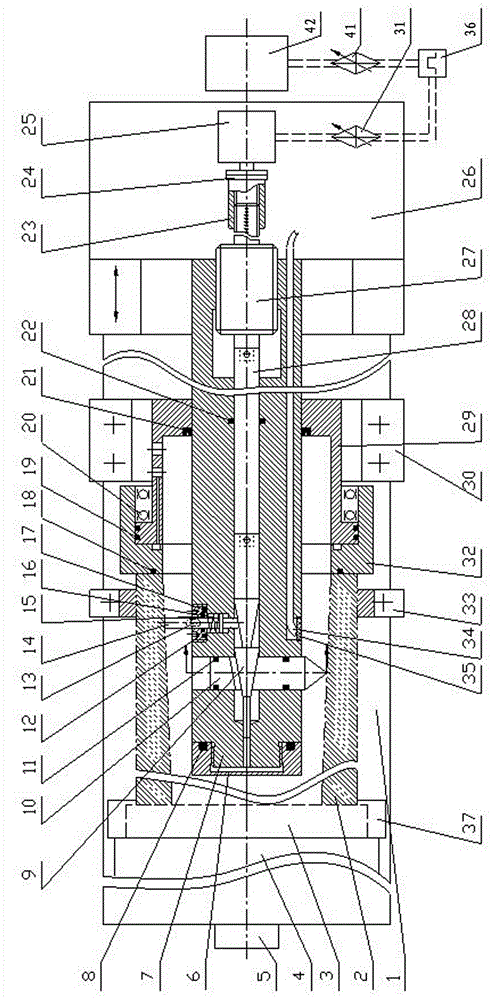

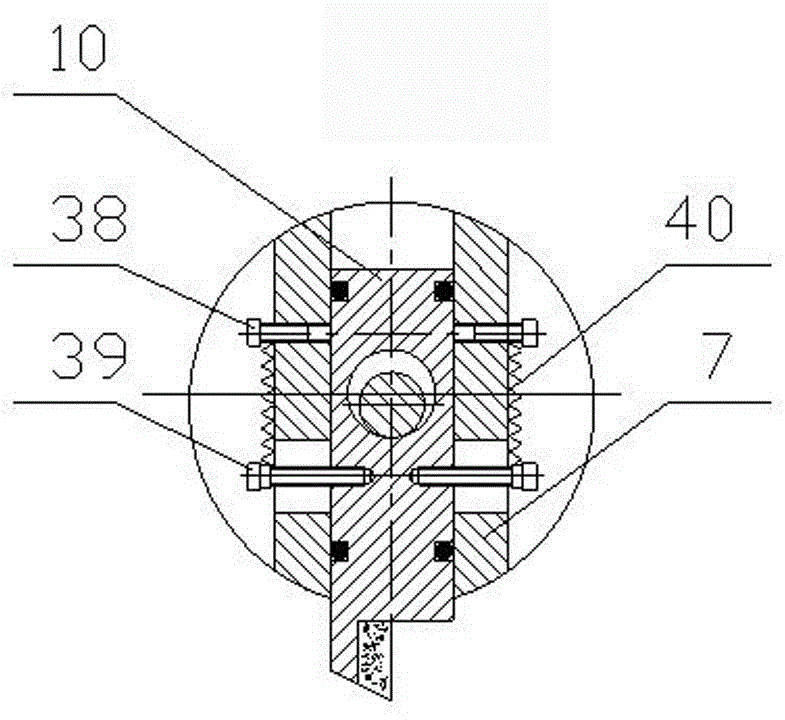

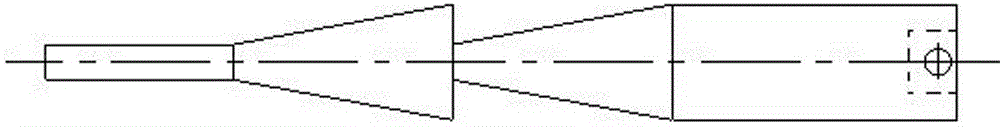

[0030] The traditional deep-hole machine tool itself has the function of boring. The invention reforms the deep-hole machine tool to complete conical deep-hole boring. The remanufactured parts include boring bar 7, boring cutter 10, double cone core rod 9, cylindrical core rod 28, screw spline core rod 27 and other parts. The three-jaw chuck 3 on the spindle box 4 of the deep-hole machine tool clamps the workpiece 2 with the tapered deep hole, and the center frame 33 presses the other end of the workpiece.

[0031] The oil feeder bracket 30 is fixed on a certain position of the guide rail of the bed 1 according to the length of the workpiece. The oil feeder bracket 30 is fixedly connected with the oil feeder seat 29, and one end of the rotary member 32 is mounted on the oil feeder seat 29 through a bearing. The other end is in contact with the end surface of the workpiece.

[0032] One end of the boring bar 7 is fixedly connected with the sliding plate 26, and the boring bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com