Low-silver lead-free solder paste soldering flux with high ductility

A silver lead-free solder paste, ductility technology, applied in the direction of welding/cutting media/materials, welding media, manufacturing tools, etc., can solve problems such as solder instability, improve stability, improve cracking, anti-corrosion and The effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention are described in detail below.

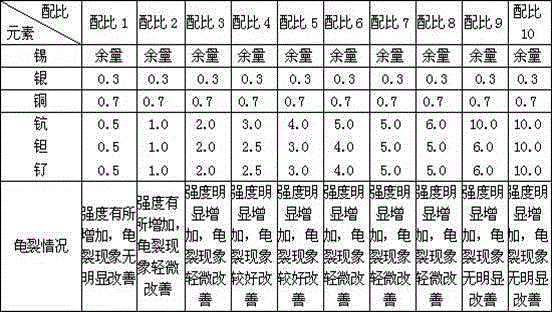

[0010] This high-ductility, low-silver, lead-free solder paste contains tin, 0.3 percent silver and 0.7 percent copper as the main component of the solder, which also includes scandium, tantalum and ruthenium. The inventor has been engaged in solder research for many years, and found in many years of production practice that during the soldering process of circuit boards, the low-silver lead-free solder paste solder is not very hot, and the strength is seriously insufficient, and the solder will open. and cracking phenomenon, although the cracking is very small, it has a very large impact on product quality. The inventors have made statistics and found that the quality problems caused by open welding and cracking account for about 60% of welding quality problems. Therefore, improving the ductility of solder becomes the key to solving the problem. The inventor started with the addition of rar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com