Sterile material transport device

A transfer device and material technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of inconvenient transportation and assembly, affecting the transfer speed, and many transfer actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

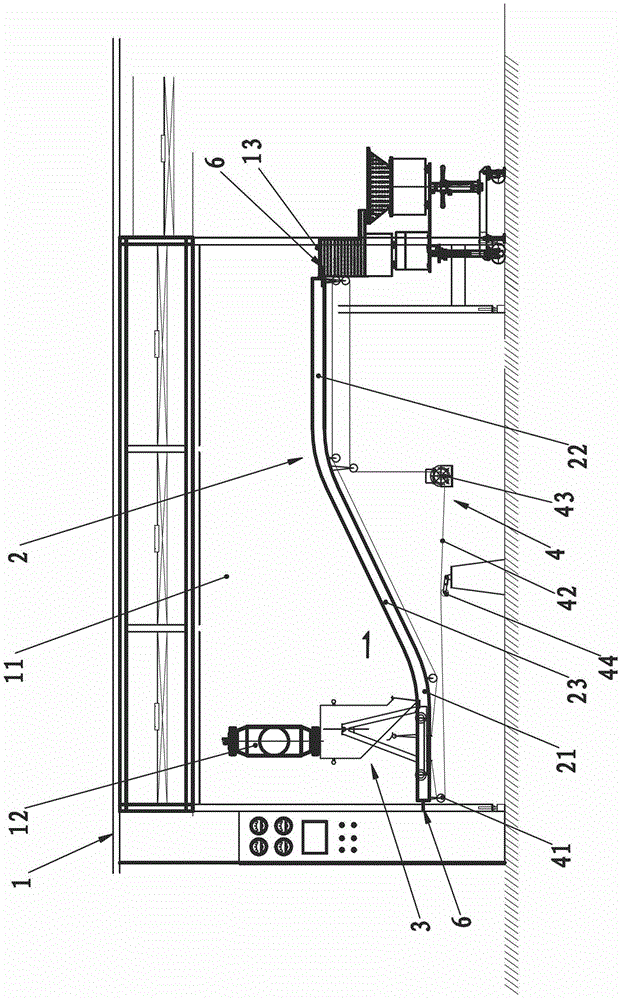

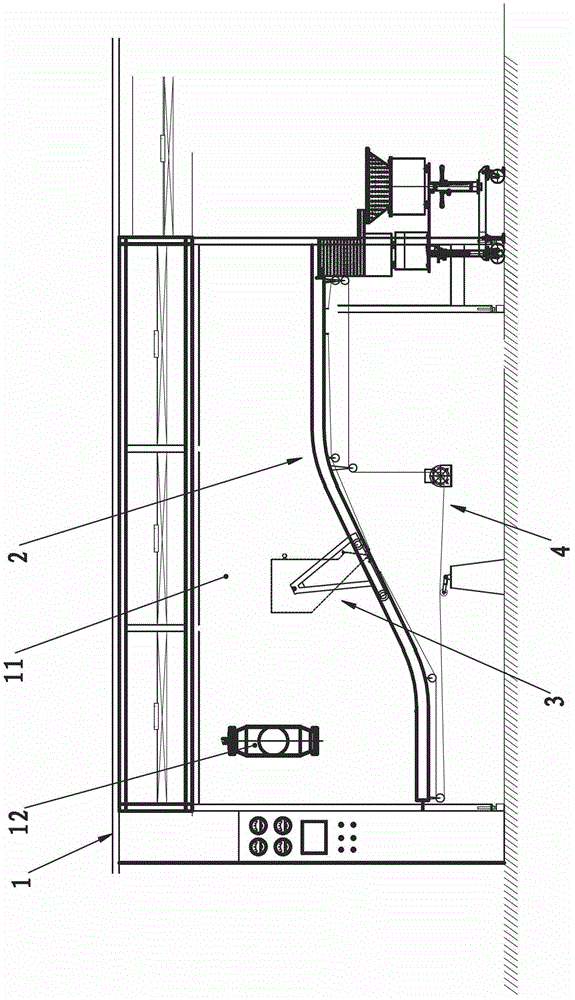

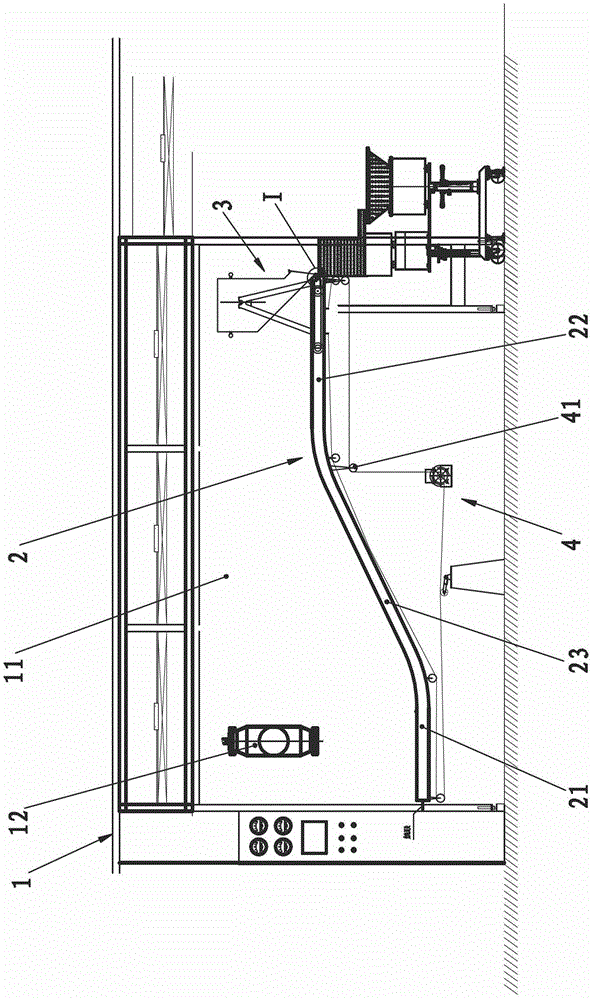

[0020] Such as figure 1 — Image 6 The aseptic material transfer device shown includes a box body 1 with a sterile space 11, a track 2 located in the sterile space 11, a transfer vehicle 3 that can run along the track 2, and a drive that drives the transfer vehicle 3 to run. Mechanism 4, one end of the track 2 in the transverse direction of the box body 1 is the input end 21, and the other end is the output end 22, the box body 1 is located at the corresponding place of the input end 21 and is provided with a material receiving port 12, and the box body 1 is located at its output end 21 is provided with a discharge port 13 connected with external equipment, the input end 21 and output end 22 of the track 2 are arranged in parallel, and the position of the output end 22 in the sterile space 11 is higher than the input end 21, the input end of the track 2 The end 21 and the output end 22 are connected by an inclined transfer end 23; the transfer vehicle 3 includes a transport f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com