Gantry-type double-arm palletizing robot and corrugated paper palletizing device with gantry-type palletizing robot

A palletizing robot, gantry-type technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of low efficiency, high scrap rate, waste of human resources, etc., to achieve efficiency, avoid scrap, improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

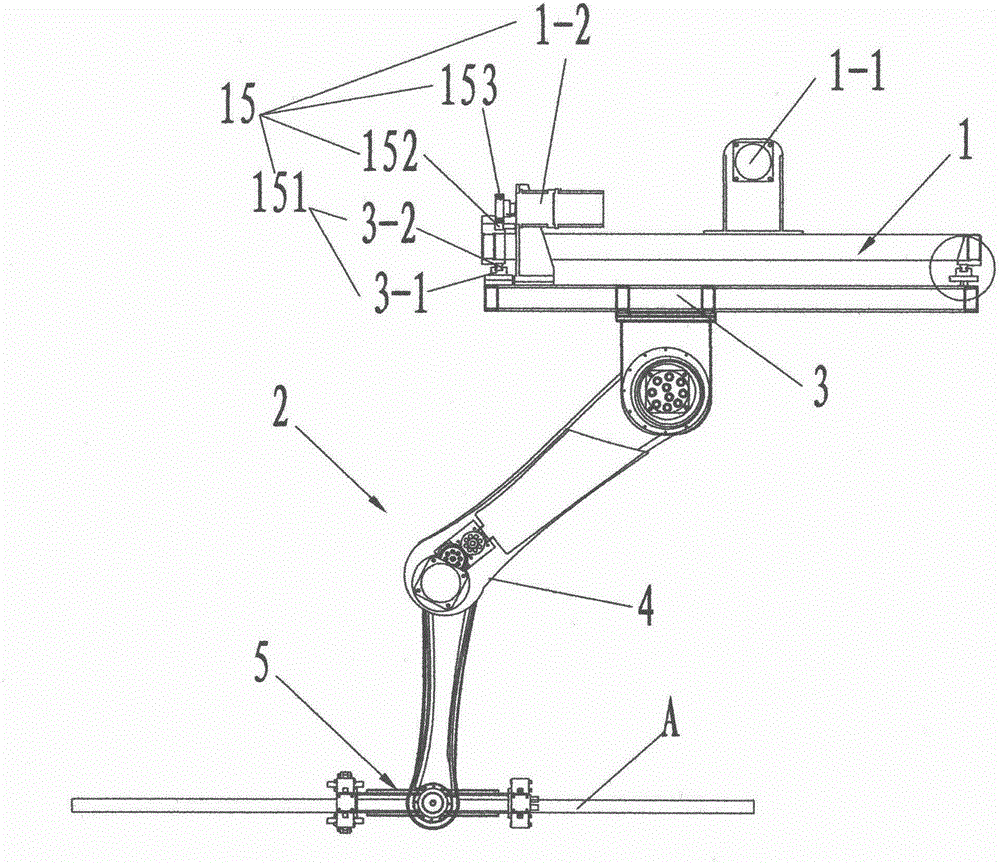

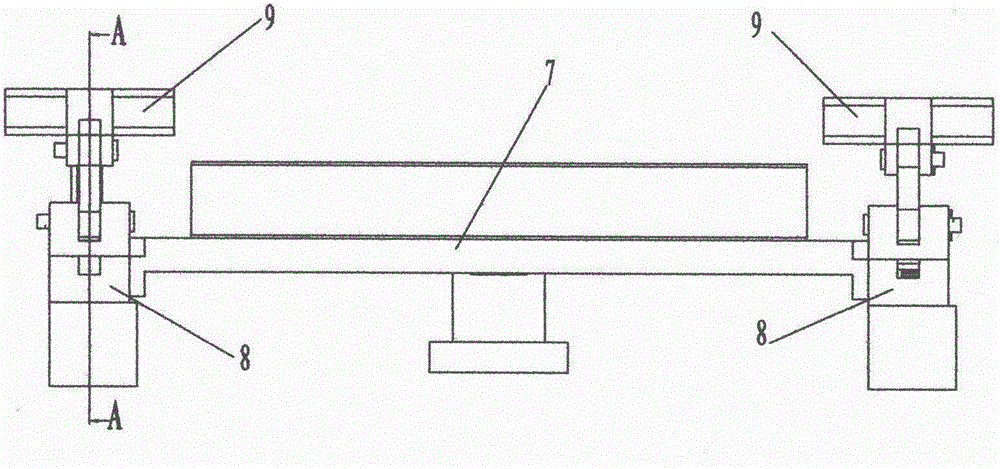

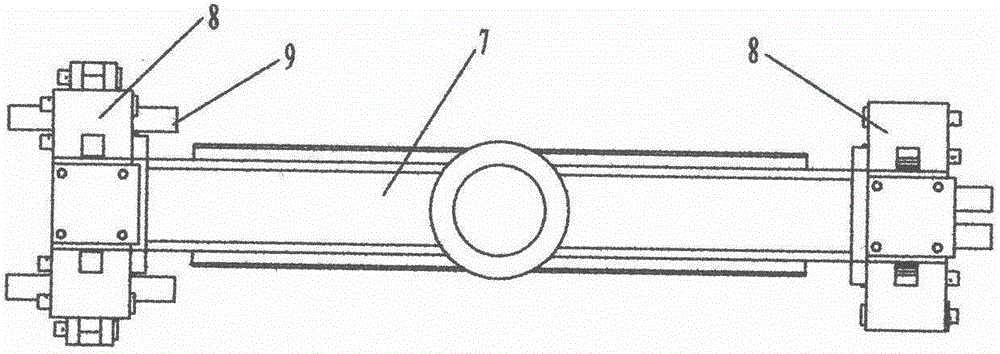

[0034] Such as Figure 1 to Figure 6 The gantry-type double-arm palletizing robot shown includes a mobile frame 1, and a movable gripper 2 is arranged on both sides of the mobile frame 1. The joint rotation of the gripper 2 is driven by a servo motor, and can be straightened and bent. , raising, lowering and other arm joint movements. The movement of different positions within the X / Y / Z three-axis coordinates can be realized through the cooperation of the gripper 2 and the moving frame 1 . The gripper 2 is composed of a fixed seat 3 , a double-section arm 4 and a gripper 5 . A moving device 15 is arranged between the fixed seat 3 and the mobile frame 1, and the moving device 15 includes an adjustment guide rail 151, a gear track 152, an adjustment gear 153, and a servo motor 1-2. The adjustment guide rail 151 is a pair of installation The trapezoidal concave groove 3-1 of the fixed seat 3 and the trapezoidal protrusion 3-2 matched with the trapezoidal concave groove of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com