Method for producing transparent ceramic fluorescence substrate used for LED

A technology of transparent ceramic and fluorescent substrate, applied in the field of LED light source, can solve the problems of affecting the quality of light output, restricting mass production and yield, affecting the uniformity of light output, etc., to achieve easy control of thickness, good uniformity of light output, and improved consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

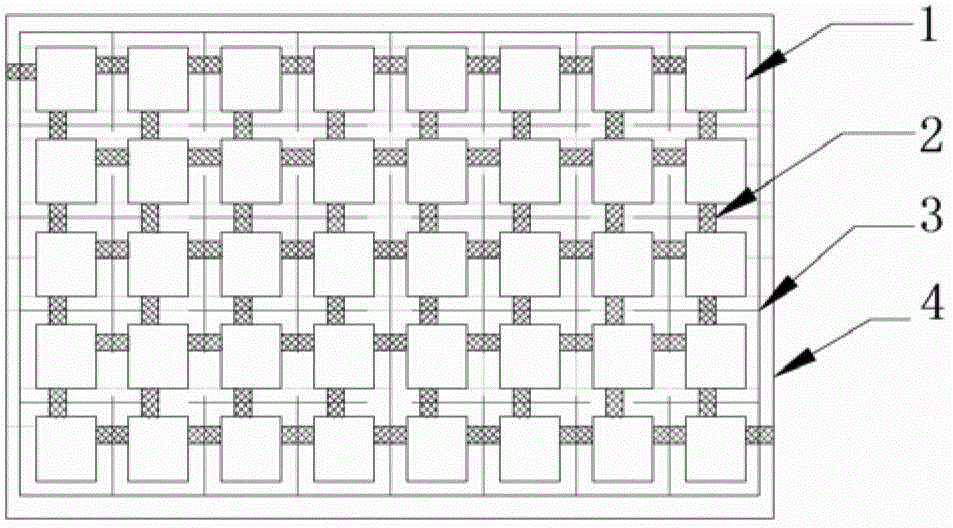

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

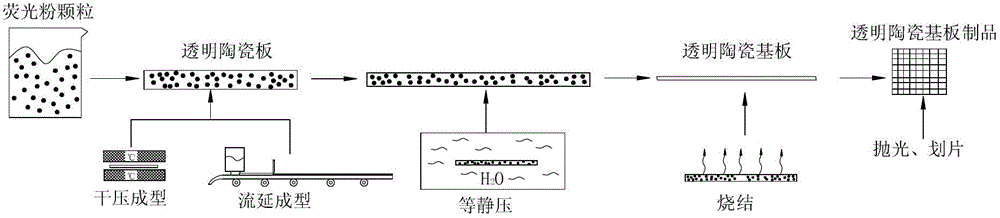

[0034] Such as figure 1 Shown is a process flow chart of a method for preparing a transparent ceramic fluorescent substrate for LEDs, and a specific step is described below:

[0035] (1) Mixture: chemically synthesize a mixture of one or more than two phosphors and yttrium aluminum pomegranate at a molar ratio of 1:99 to form a ceramic dispersion of phosphor powder, in which yttrium aluminum pomegranate is doped with aluminate or one or both of the nitrides;

[0036] (2) Granulation: The phosphor ceramic dispersion is passed through stirring granulation method, boiling granulation method, spray drying granulation method, pressure molding granulation method, mold compression granulation method, extrusion granulation method, extrusion spheronization Granulation method, spray and dispersion mist granulation method or hot melt molding granulation method or a combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com