Method for preparing low-chromatic number isocyanate and isocyanate prepared by same

A technology of isocyanate and diisocyanate, applied in the field of preparation of liquid isocyanate mixture, can solve the problems of poor stability, increased viscosity, poor color number of isocyanates, etc., and achieves the effects of good stability and small viscosity change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

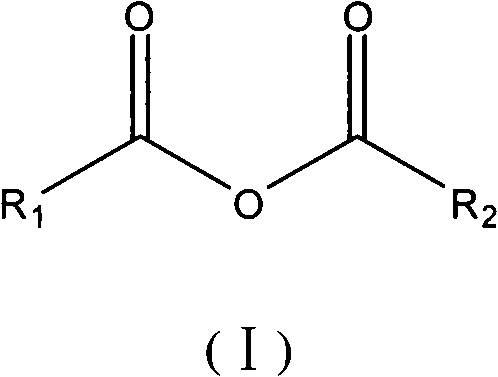

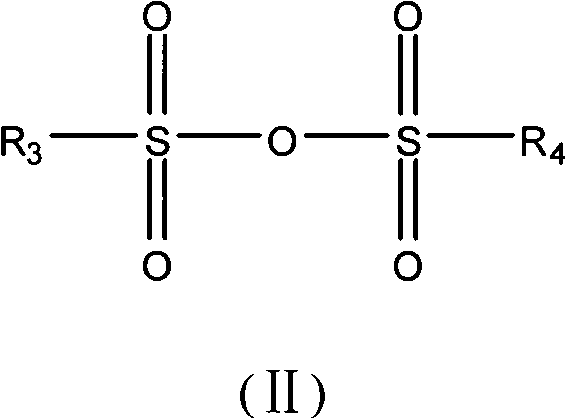

[0046] Put 2kg 4,4'-MDI in N 2 Heat to 50°C while stirring under protection, add 10ppm 3-methyl-1-phenyl-3-phosphole-1-oxide catalyst, mix and quickly heat to 100°C, add 120ppm terminator after reacting for 60min p-toluenesulfonic anhydride, and the mixture was stirred for 90 min to obtain the final product.

Embodiment 2

[0048] Put 2kg 4,4'-MDI in N 2 Heat to 50°C while stirring under protection, add 10ppm 3-methyl-1-phenyl-3-phosphole-1-oxide catalyst, mix and quickly heat to 100°C, add 230ppm terminator after reacting for 60min p-toluenesulfonic anhydride, and the mixture was stirred for 90 min to obtain the final product.

Embodiment 3

[0050] Put 2kg 4,4'-MDI in N 2 Heat to 50°C while stirring under protection, add 10ppm 3-methyl-1-phenyl-3-phosphole-1-oxide catalyst, mix and quickly heat to 100°C, add 500ppm terminator after reacting for 60min p-toluenesulfonic anhydride, and the mixture was stirred for 90 min to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com