Composite active black dye

A technology of reactive black and dyes, applied in the field of dyes, can solve the problems of finished fabrics such as hard hand feeling, unsatisfactory blackness, and poor compatibility, etc., and achieve high perspiration fastness and soaping fastness, easy washing and economical excellent solubility and solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

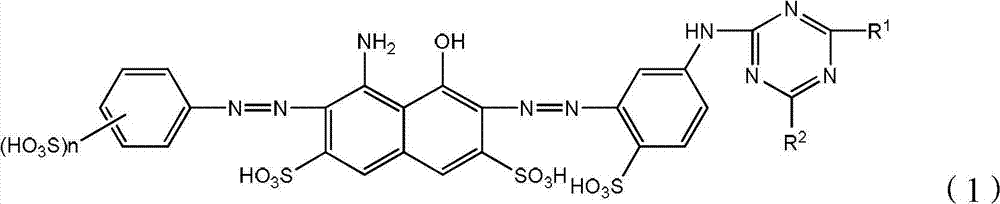

Image

Examples

Embodiment 1~9

[0039] According to the data in Table 1, the dye component A, dye component B, dye component C and auxiliaries are mixed evenly using blending equipment, or the liquid slurry is directly mixed evenly.

[0040] Dye component A, dye component B, and dye component C can be prepared by methods well known in the art, for example: the CAS number of the compound shown in formula 1-2 is 68259-02-9; the compound shown in formula 2-2 The CAS number of the compound is 70161-16-9, and the Chinese patent with the notification number CN100567404C discloses the preparation method of such compounds as components A and B; the CAS number of the compound shown in formula 3-3 is 413568-01-1 , see [Effect of Dye Structure on the Interaction between Organic Flocculant PAN-DCD and Dye, Industrial & Engineering Chemistry Research (2002), 41 (6), 1589-1596].

[0041] Take the dye component C as an example: for example: the compound (3-3) in the dye component C can be synthesized in the following ways:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com