Method for deoxidation in ladle furnace (LF) refining furnace by using low calcium ferro-manganese-aluminium

A low-calcium-aluminum-ferromanganese and refining furnace technology is applied in the field of steelmaking to achieve the effect of improving the quality of steel and reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

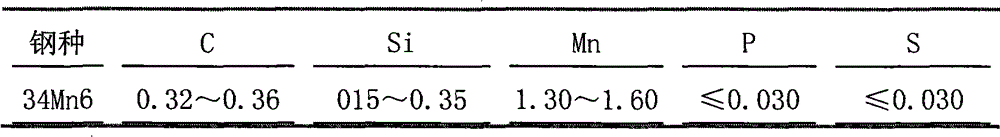

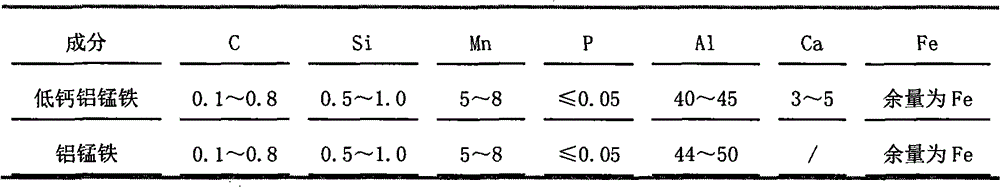

Method used

Image

Examples

Embodiment 1

[0019] (a) In the LF refining furnace, low-calcium aluminum manganese ferromanganese is used to carry out deoxidation alloying, and the amount of molten steel is 93.3 tons, and the addition is 50kg;

[0020] (b) Take a slab sulfur stamp sample to test the total oxygen content and aluminum addition in the steel;

[0021] (c) Take the billet for sulfur stamp inspection.

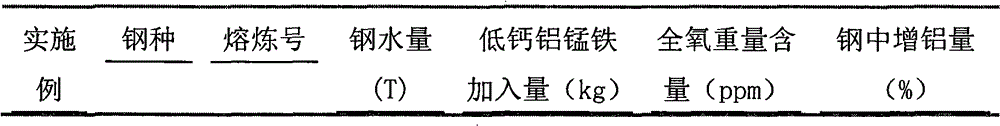

[0022] The test method of embodiment 2~embodiment 3 is the same as embodiment 1, and its specific data are shown in table 3.

[0023] Table 3 is the sampling analysis result of Examples 1-3 by the method of the present invention.

[0024] Table 3 Total oxygen content and aluminum increase in steel after adding low calcium Almanganese ferromanganese deoxidation in LF furnace

[0025]

[0026]

[0027] Table 4 is the sampling and analysis results of Examples 4-6 by adding Almanganese ferroalloy to LF furnace and using the method of the present invention.

[0028] Table 4 The total oxygen content and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com