Damping device of swing arms of slipping steering loaders

A technology of skid steering and vibration damping device, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve problems such as changes in vibration damping effect, no overflow valve, loss of vibration damping function, etc., to increase reliability, The effect of avoiding deterioration of vibration damping effect or failure of vibration damping, reducing procurement cost and debugging workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

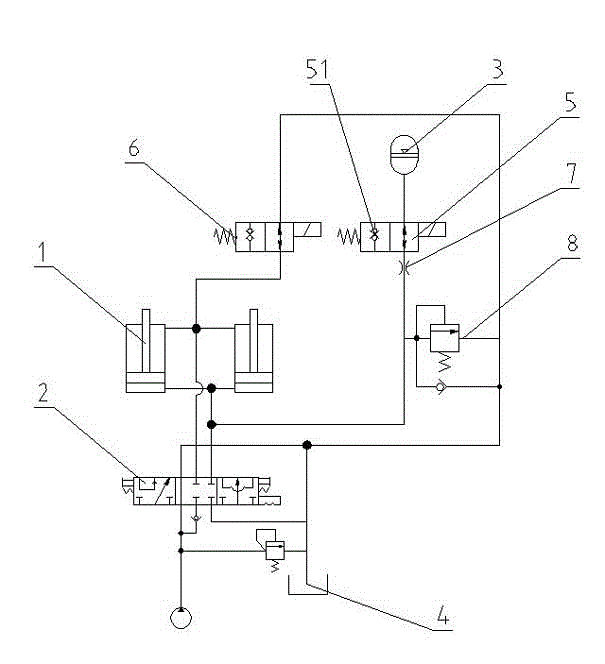

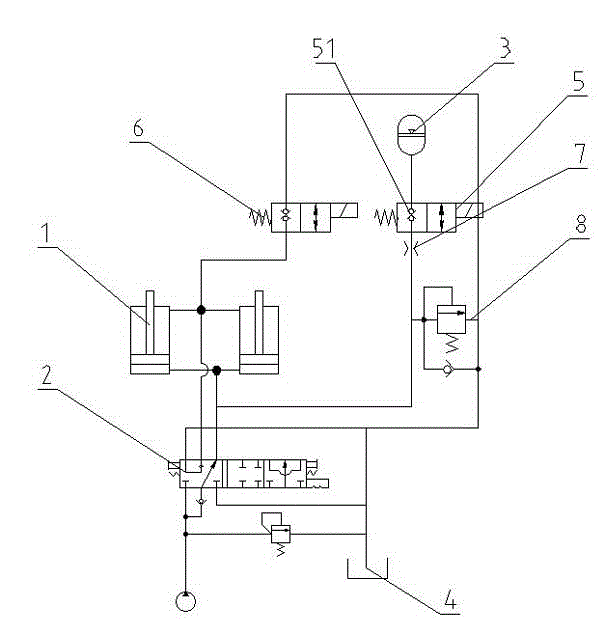

[0017] Such as figure 1 As shown, a skid steer loader arm vibration damping device includes a boom cylinder 1, a three-position six-way valve 2 for controlling the boom cylinder 1, an accumulator 3 and a fuel tank 4, and also includes a first two-position The two-way solenoid valve 5 and the second two-position two-way solenoid valve 6, the first two-position two-way solenoid valve 5 includes a zero-leakage plug-in stop valve 51; The accumulator 3 is connected through the oil pipe, and the first two-position two-way solenoid valve 5 is set on the pipeline between the large cavity of the boom cylinder 1 and the accumulator 3; the small cavity of the boom cylinder 1 is connected through the second two-way The position two-way electromagnetic valve 6 is connected with the oil tank 4.

[0018] When the skid steer loader needs to absorb the vibration and impact on the boom cylinder 1 during the transportation of materials, the three-position six-way valve 2 is in the neutral posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com