Multi-terminal parameter monitoring system for coal mine underground tunnel drilling rig

A tunnel drilling rig and parameter monitoring technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well parts, etc., can solve problems such as personal injury that is difficult to avoid, and achieve the effect of flexible display mode, convenient installation, and multiple display terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

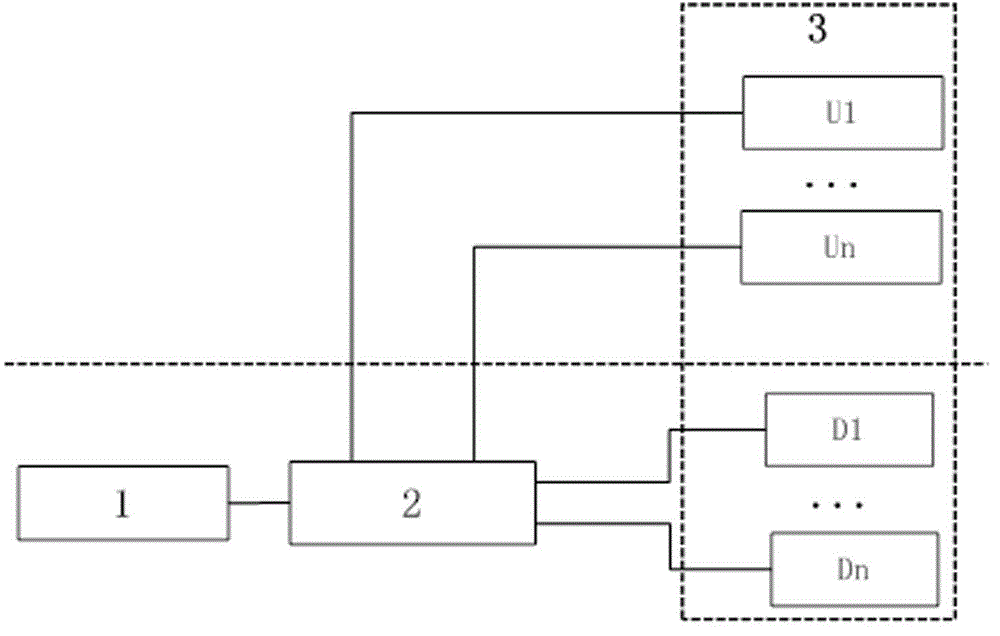

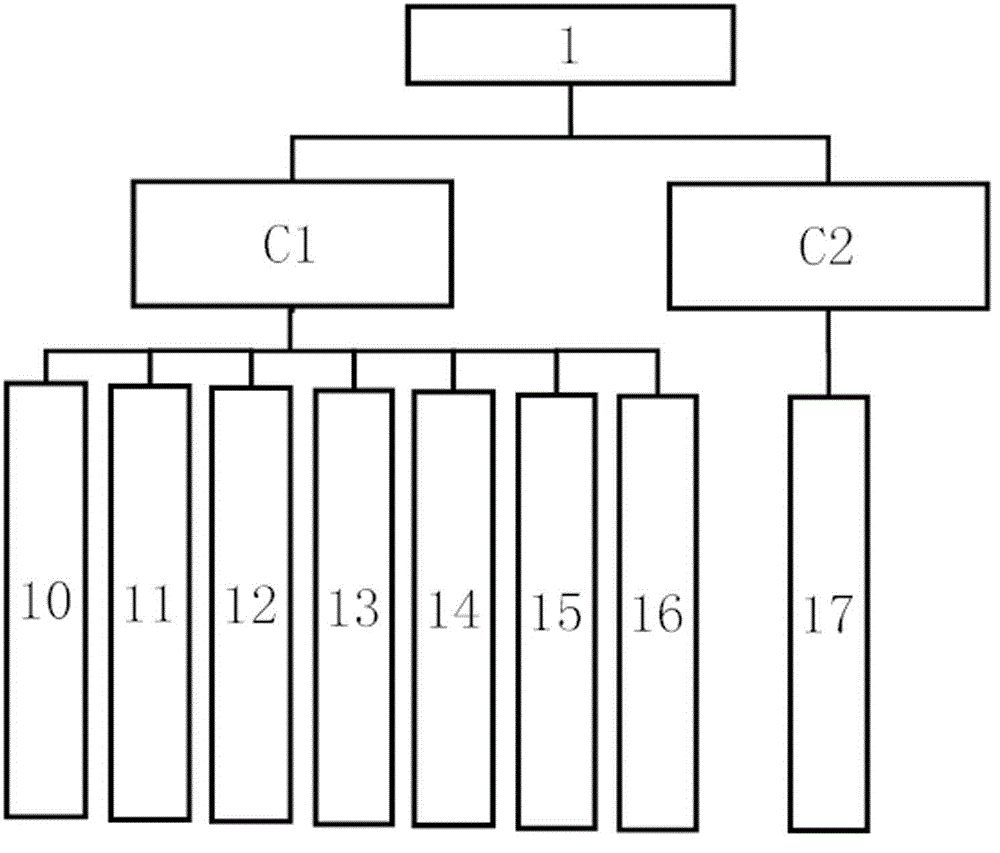

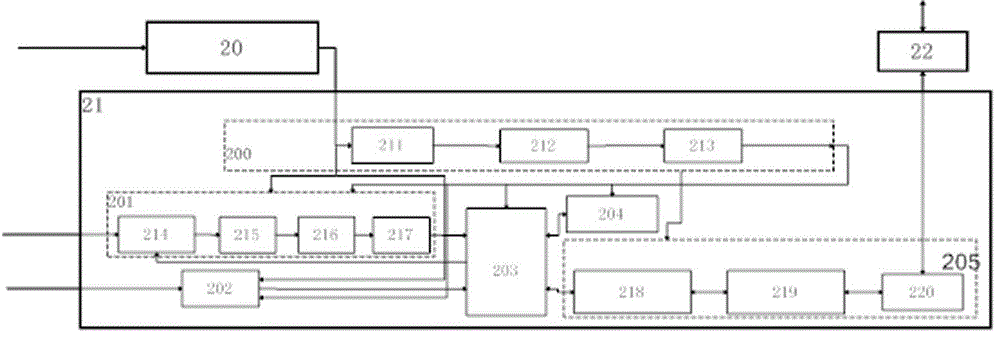

[0023] The basic principle of the present invention is: the sensor assembly collects the parameters of the on-site tunnel drilling machine, converts them into analog or digital signals, and sends them to the microcontroller for processing after being conditioned by the signal conditioning circuit in the on-site control box; The packet format is sent to the communication 485 bus, and then the electric-optical conversion module inside the control box converts it into an optical signal output, and then distributes the optical signal to each display terminal through an optical splitter; each display terminal receives the optical signal Then restore it to 485 electrical signals, and then extract the parameters collected by each sensor according to the format of the obtained communication data packets, judge whether there is a fault by each paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com