Direct-current electric grease gun

A technology of grease gun and DC motor, which is applied in the direction of engine components, engine lubrication, lubricating oil control valve, etc. It can solve the problems of complex structure of electric grease gun, easy jamming of slider, aging of oil seal solution and oil leakage, etc. Achieve the effects of small friction, stable pressure value and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

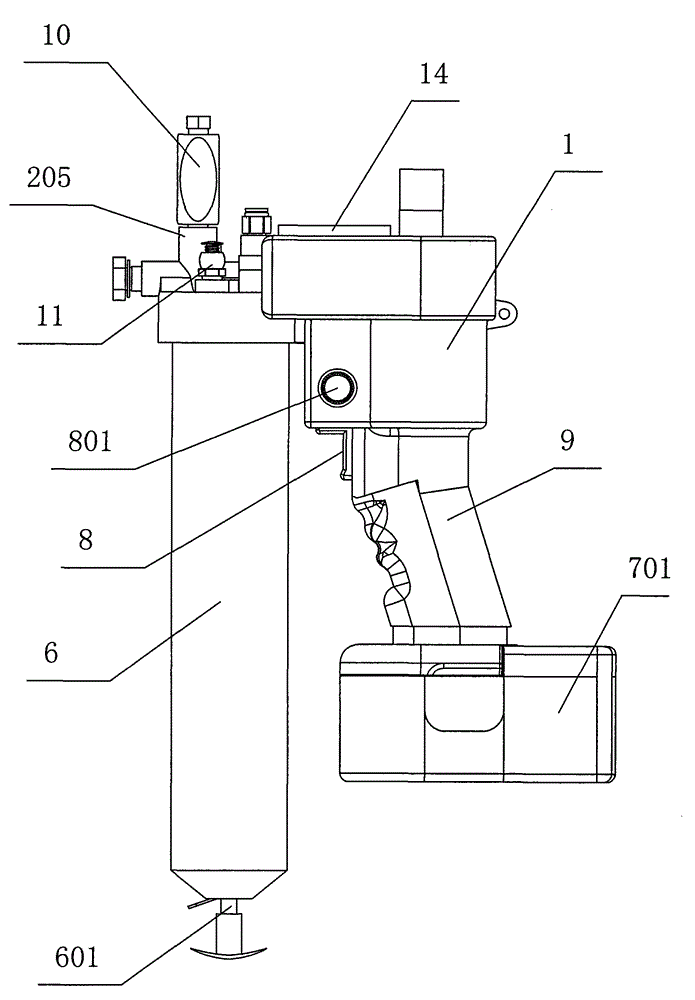

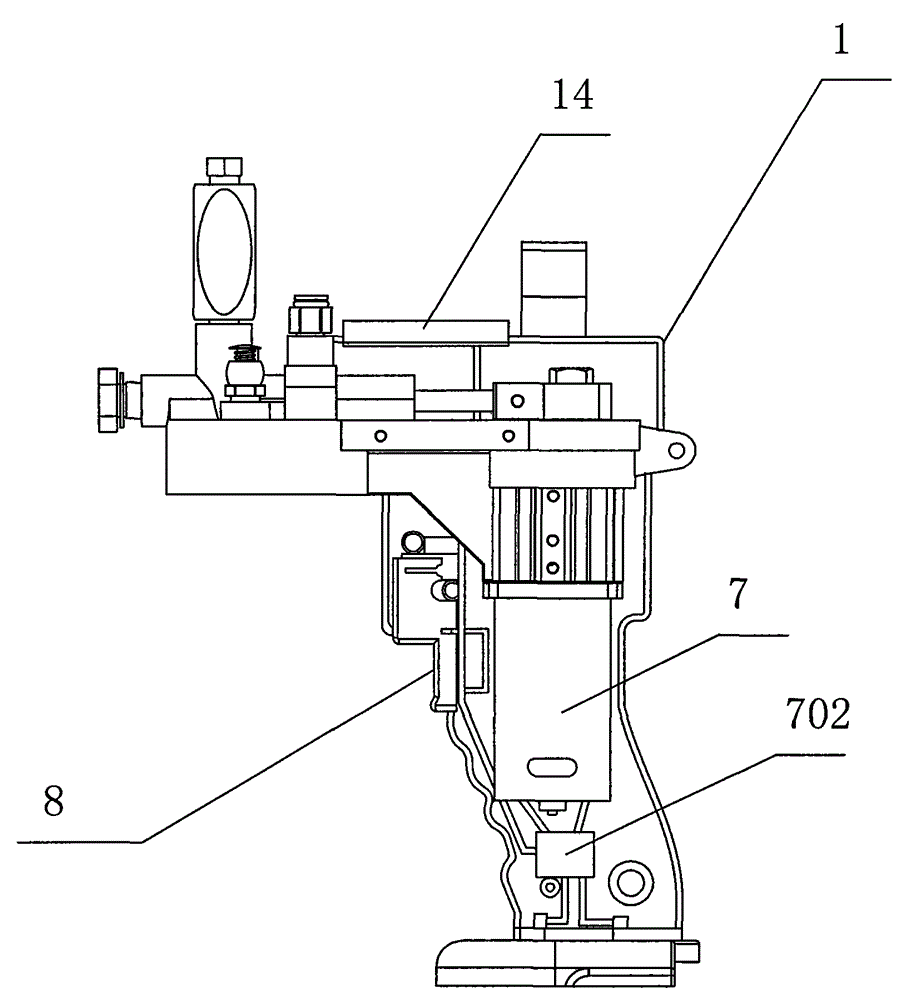

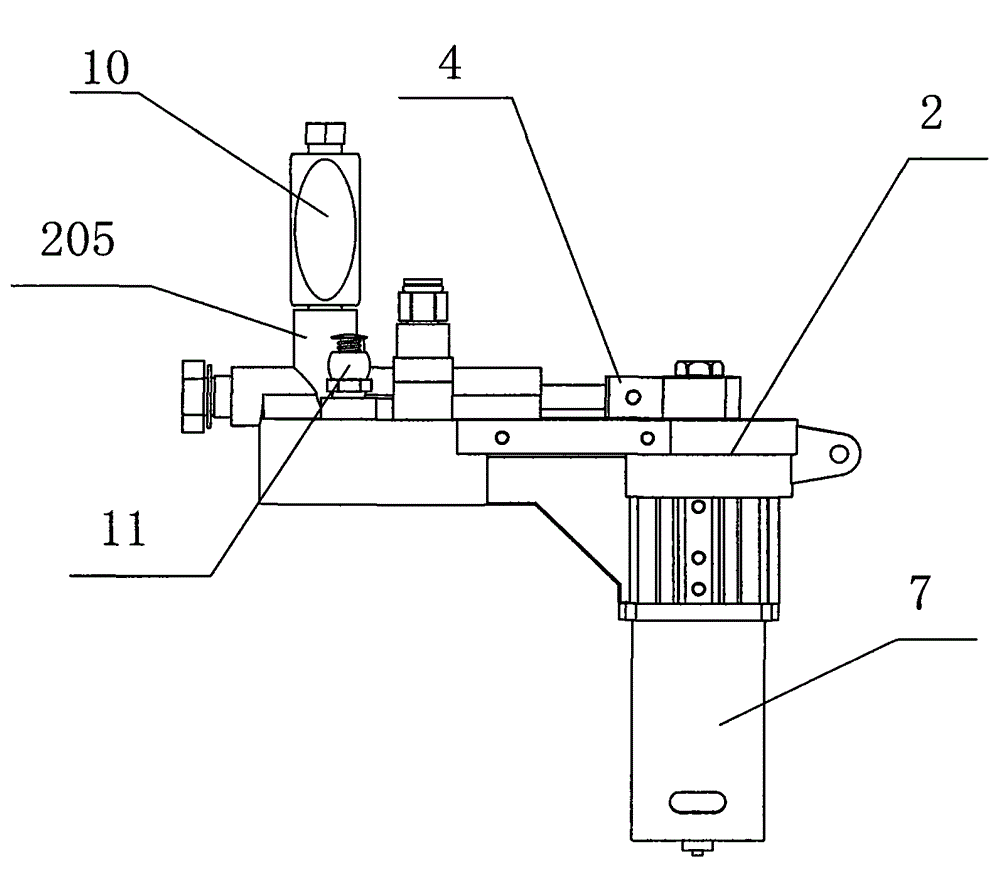

[0030] Such as Figure 1-1 to Figure 7As shown, a DC electric grease gun includes an outer packaging shell 1, a body 2, a one-way valve 3, a rotation and reciprocating motion conversion mechanism 4, a planetary reduction mechanism 5, an oil storage cylinder 6, a driving mechanism, an operating mechanism, and a connector. Nozzle 10, deflation valve 11 and refueling valve 12; the body 2 includes a table top 201, a slide bar hole seat 202 at the top front, a table hole 203 at the top rear, an oil storage cylinder connection screw hole 204 at the bottom front, and a screw hole 204 at the bottom rear. The planetary reduction mechanism housing part 207, and the oil outlet 205 and the oil inlet 206, the front of the slide rod hole seat 202 is provided with a one-way valve cavity 208, and the rear part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com