LED fluorescent lampshade and manufacturing method thereof

A manufacturing method and LED wick technology, applied in the field of LED lighting, can solve the problems of poor repeatability of phosphor coating, affecting the quality of light output, affecting the uniformity of light output, etc., so as to eliminate the conversion efficiency of phosphor powder, and achieve stable and uniform light output. Good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

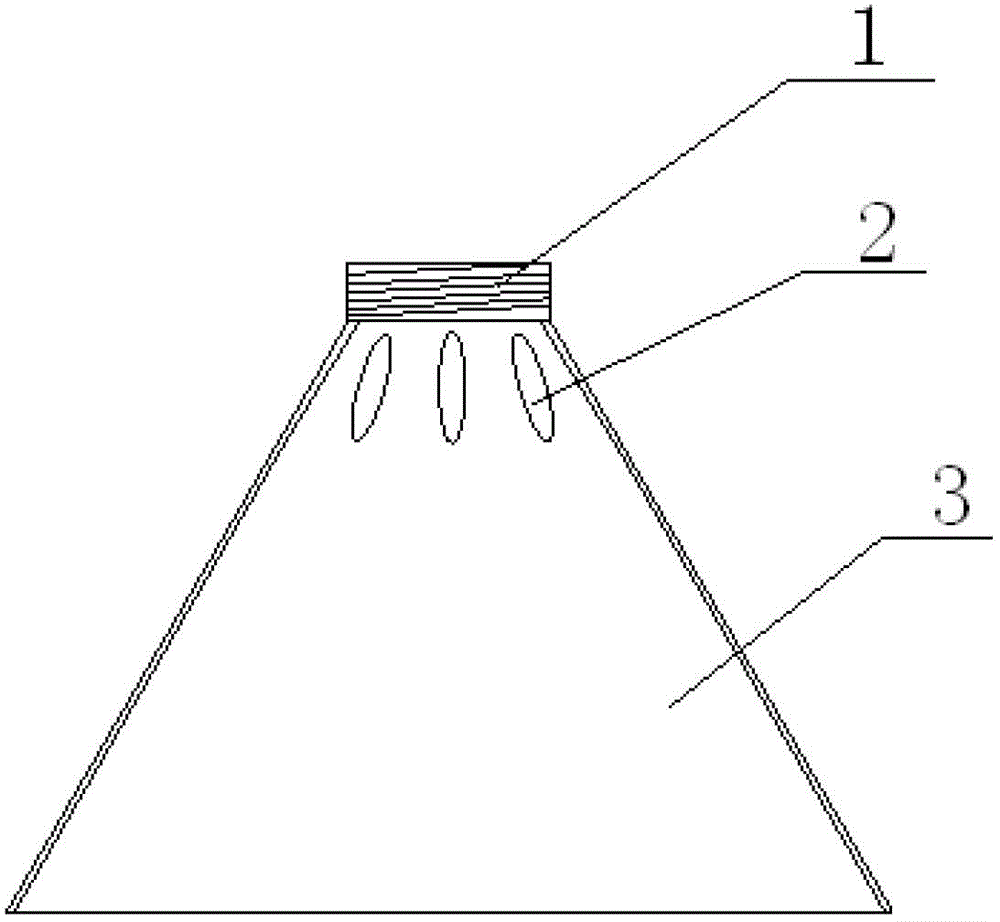

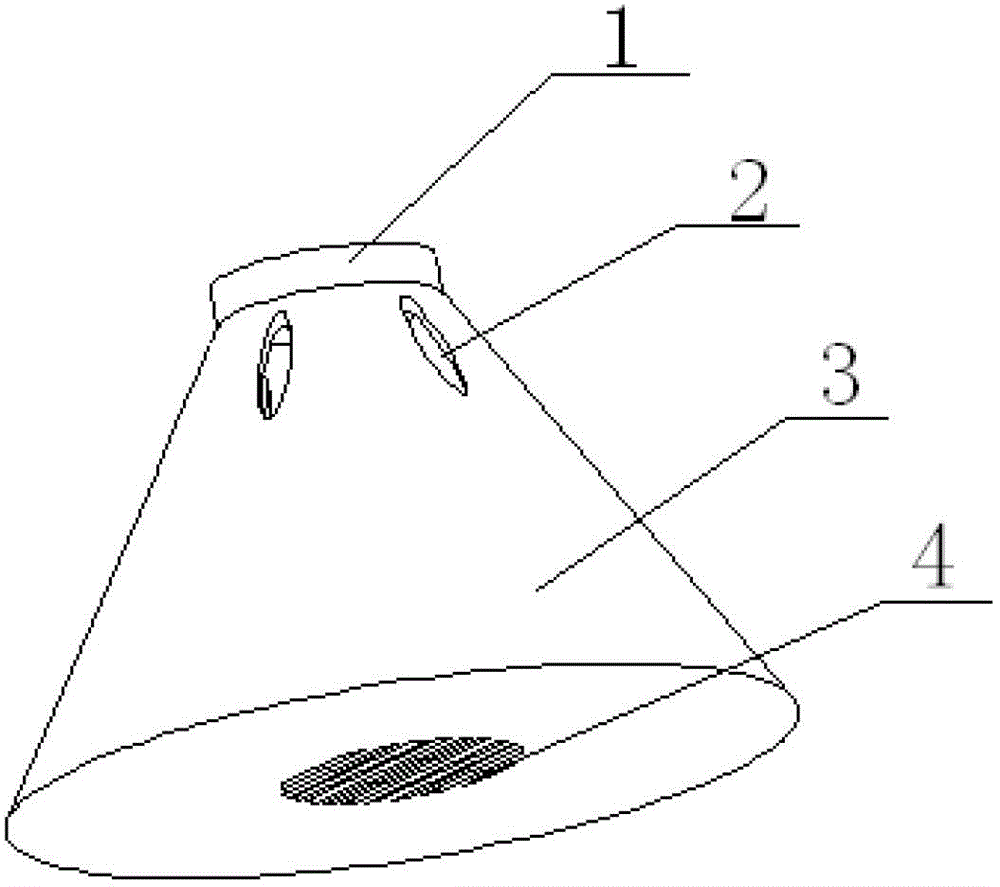

[0033] like figure 1 , figure 2 Shown is an integrally formed LED fluorescent lampshade, which includes a lamp cap connecting part 1 and an LED wick accommodating cavity 3. The outer wall of the accommodating cavity 3 is provided with a heat dissipation through hole; the lamp head connecting part 1 is a threaded structure; the wick accommodating cavity 3 is a conical platform structure, the LED wick insertion port is set on the small end surface, and the heat dissipation through hole is set On the side surface and the large end surface, the heat dissipation through holes located on the side are marked as side wall heat dissipation holes 2, and the heat dissipation through holes located on the large end surface are marked as bottom wall heat dissipation holes 4, and the heat dissipation holes on the bottom wall are hollowed out structures of stripe groups.

[0034] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com