Non-metallic energy oil steam generation method and generation device of no-pressure container

A pressure vessel, non-metallic technology, applied in the field of non-metallic energy oil vapor generation method and generating equipment in non-pressure vessels, can solve the problems of large internal pressure, unsafety, long heating time, etc., and achieve controllable and adjustable temperature and pressure , Quickly relieve stress and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

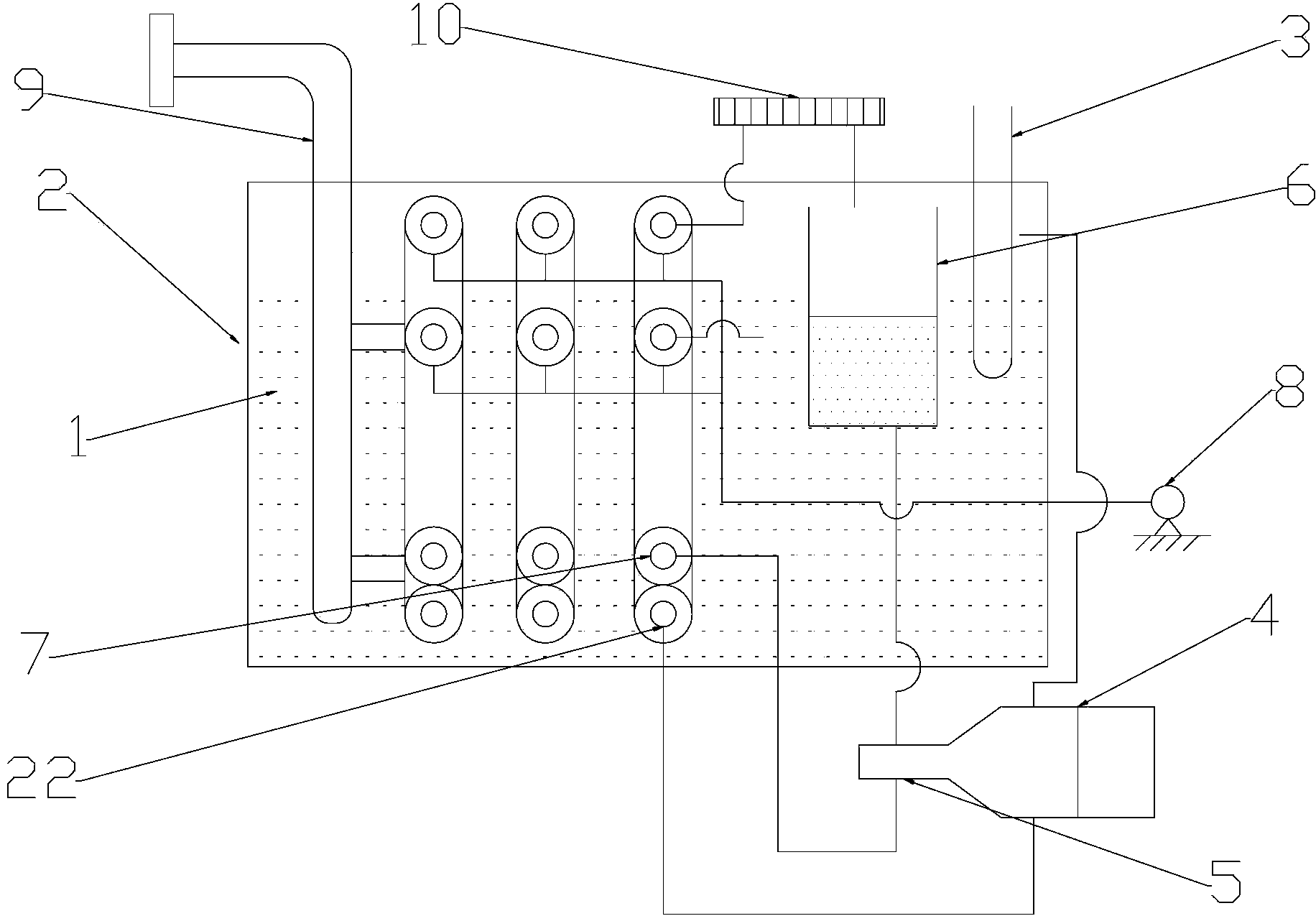

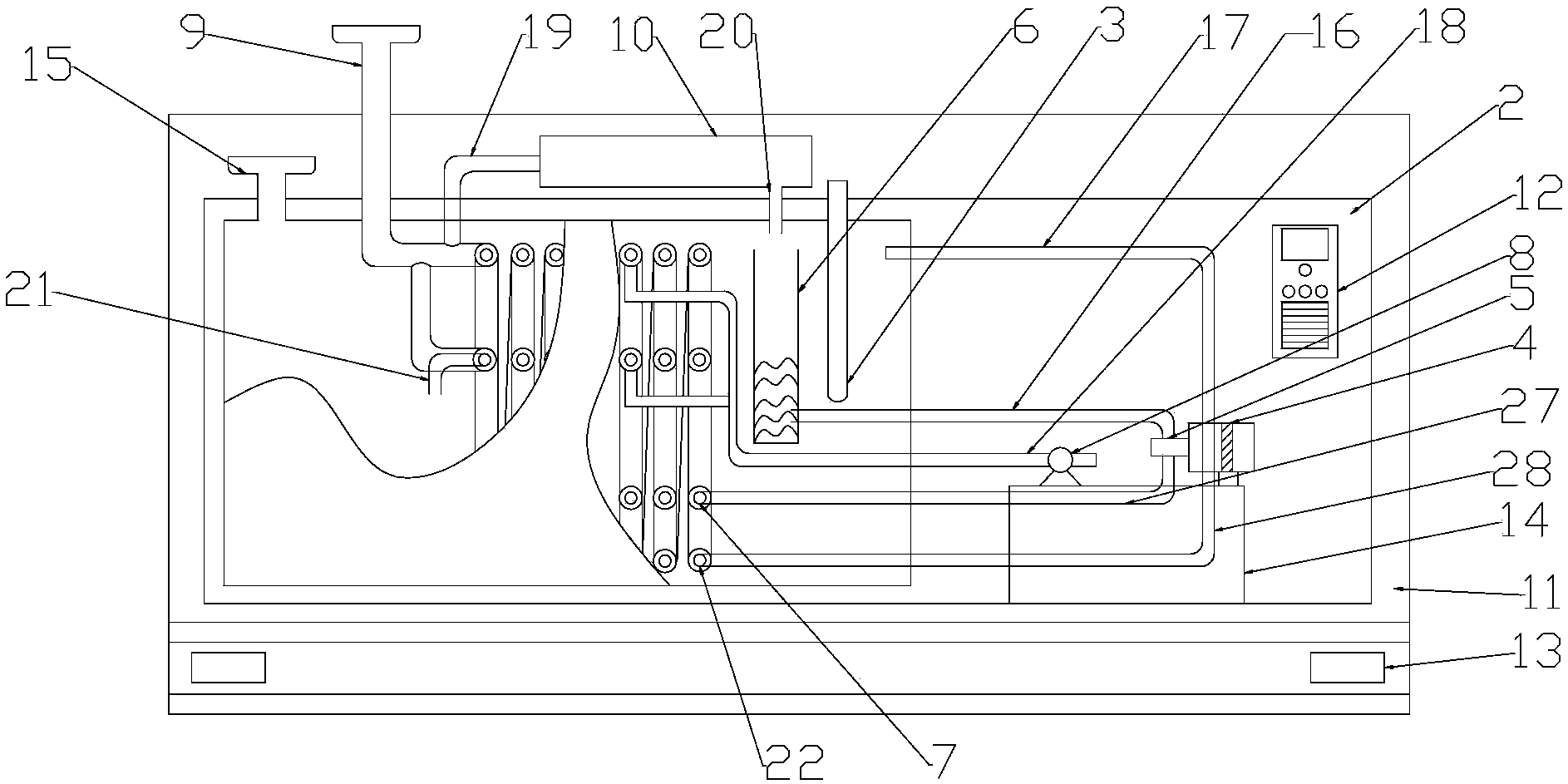

[0024] Such as figure 1 Shown, a kind of non-metallic energy oil vapor generation method of pressure vessel: comprise the following steps:

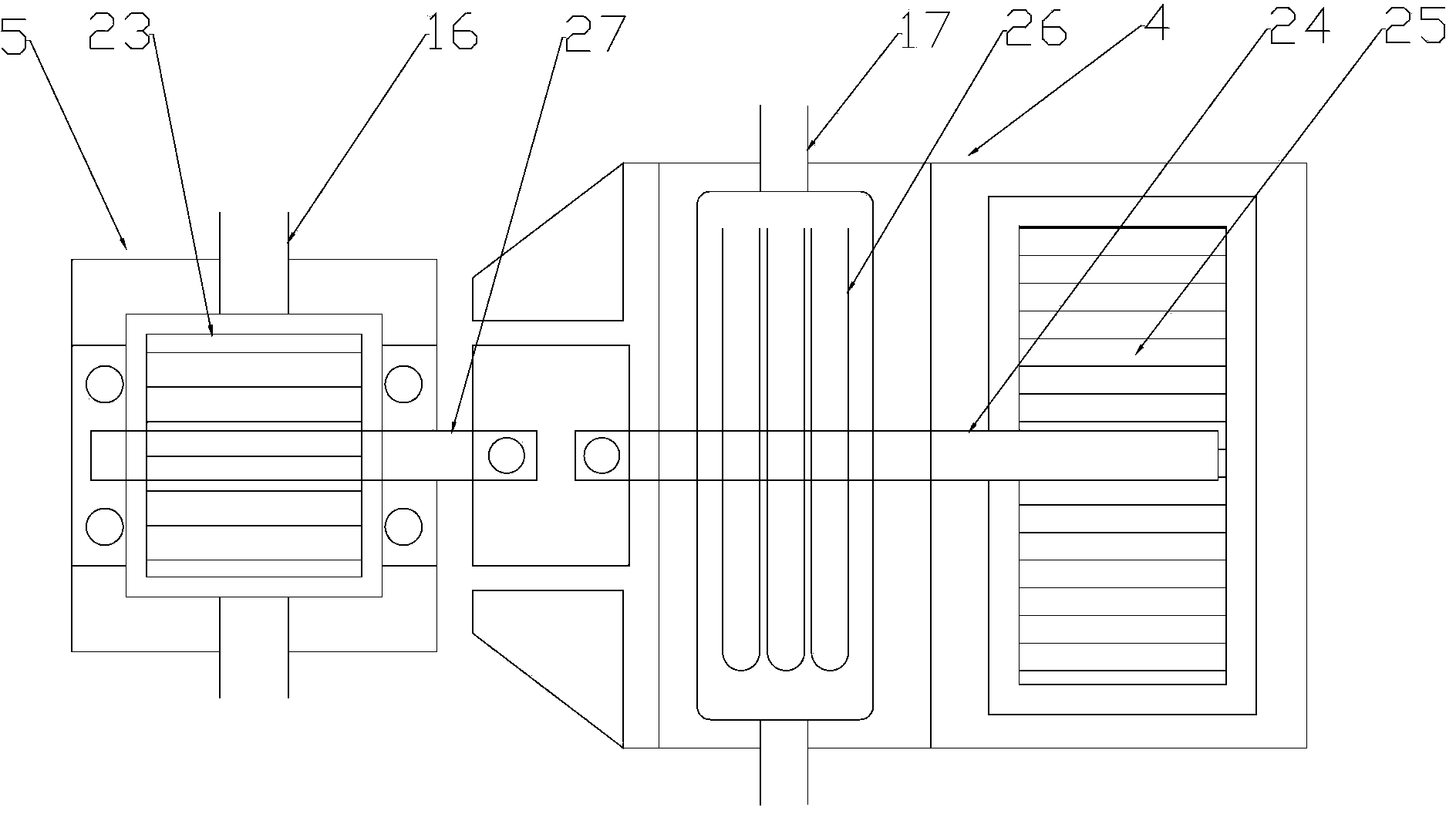

[0025] 1) After the high-carbon molecular non-metallic energy oil 1 is heated and vaporized by the heating element 3 in the oil cylinder 2, it is converted into a gaseous form, and after being inhaled and compressed by the compressor 4, the temperature of the high-carbon molecular non-metallic energy oil in the gaseous form is reduced. Elevate further; Simultaneously, the high-temperature liquid high-carbon molecule non-metallic energy oil in the oil-gas tank 6 is transported to the oil layer pipeline of the liquid-liquid heat exchange pipeline 7 through the gear pump 5, and the high-carbon m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com