Integrated afterheat hot water burner assembly

A kind of burner and integrated technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of low heating efficiency of burner assembly, reduced cooking speed, high temperature of water jacket, etc., to reduce the kitchen environment temperature , prevent waste, high heat utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

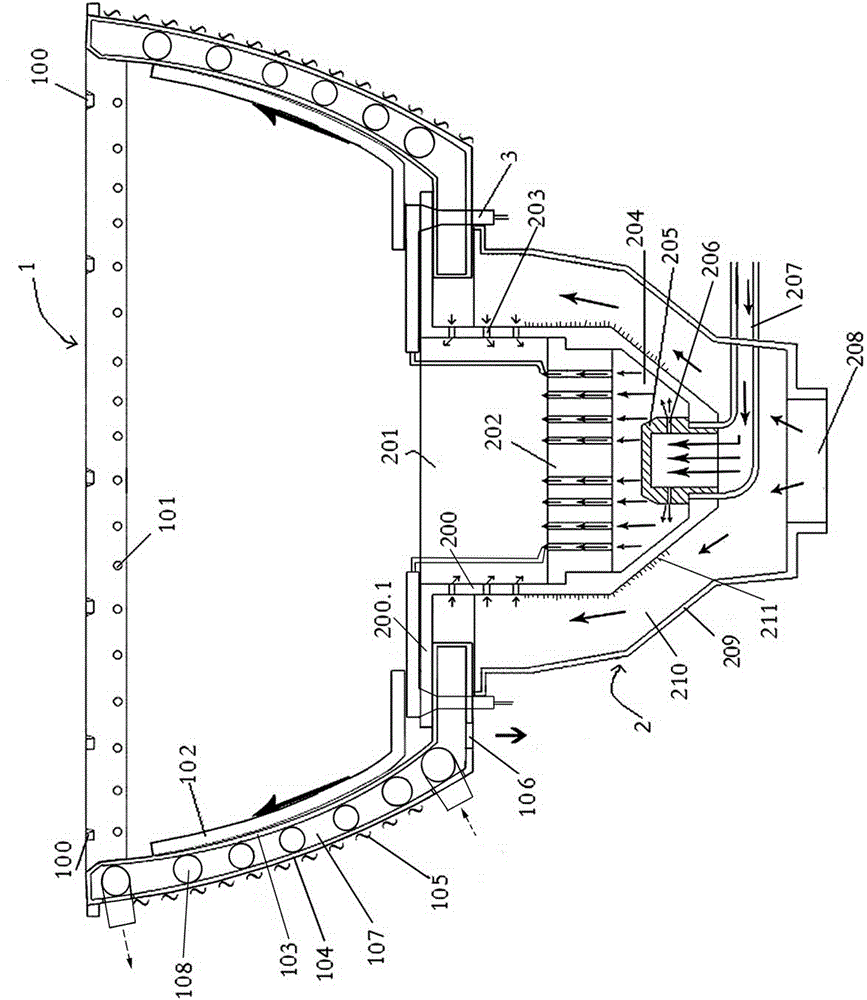

[0018] See figure 1 As shown, this integrated waste heat hot water burner assembly is composed of an ignition device 3, a burner 2, and a furnace 1 located above the burner.

[0019] The furnace 1 is a sandwich type furnace, including an inner wall 103, an outer wall 104, and an air cavity 107 sandwiched between the inner wall and the outer wall. The upper end of the inner wall is provided with several upper auxiliary exhaust gas discharge ports 100, and the inner wall is near the upper end. There are several discharge holes 101 communicating with the air chamber, and the lower part of the outer wall is provided with a lower auxiliary waste gas discharge port 106 communicating with the air chamber.

[0020] The air cavity 107 is provided with a metal water pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com