Large-capacity high-concentrating ratio composite Fresnel line concentration reflection device

A Fresnel reflection and reflection device technology, applied in the field of solar collectors, can solve the problems of uneven heating, limited improvement, uncontrollable improvement effect, etc., to achieve convenient and reasonable space layout, high concentration ratio, good The effect of the focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

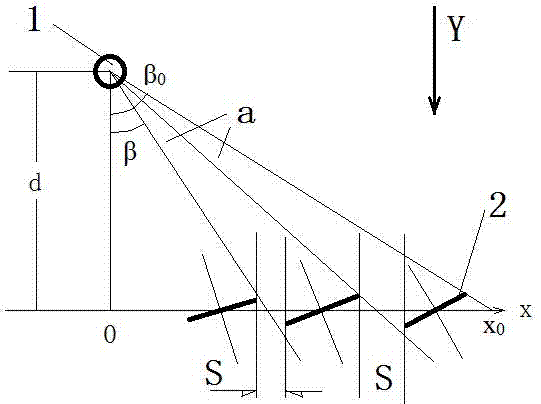

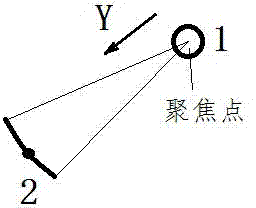

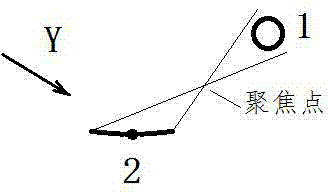

[0040] Refer to attached Figure 4 , a large-capacity high-concentration ratio composite Fresnel line light-concentrating reflector, including a main reflector 1 and a heat collecting tube 2, the main reflector 1 is composed of a plurality of micro-arc Fresnel reflectors as the main reflector, and each Fresnel The central position of the Fresnel reflector is provided with a steering device 3, and the plurality of Fresnel reflectors are located above the heat collecting tube 2, and are distributed in an arc shape with the heat collecting tube as the center and a radius of R. The main reflector 1 The angle formed between the end points on both sides of the arc segment and the center of the heat collecting tube 2 is generally 140°~160°, that is, the angle qe formed between the two ends of the arc segment and the center of the circle where the heat collecting tube 2 is located and the horizontal plane is 10~20 °. At the same time, the concave arc surface of each Fresnel reflector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com