Metal vacuum high-temperature heat collection pipe

A heat collector tube and metal inner tube technology, applied in the field of solar energy applications, can solve the problem of inability to obtain high temperature, and achieve the effects of improving heat collection efficiency, reducing the number of use, and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

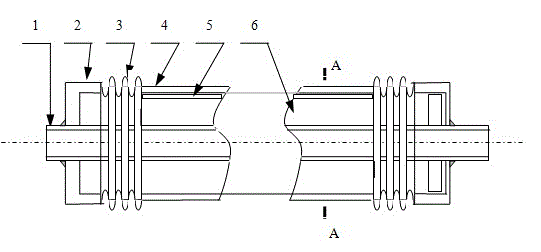

[0021] The present invention will be further described below in conjunction with the drawings.

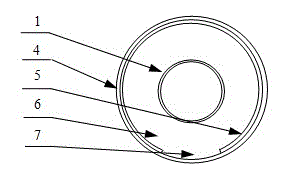

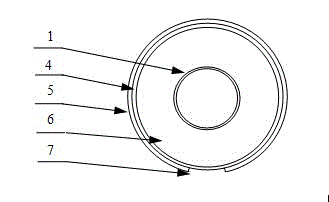

[0022] by figure 1 It can be seen that the metal vacuum high-temperature heat collection tube includes a glass outer tube 4, a metal inner tube 1, a corrugated tube 3, and a connecting flange 2 penetrating through the glass outer tube 4. The outer wall of the metal inner tube 1 is coated with an anti-reflection layer, and the glass outer tube 4 A bellows 3 is hermetically connected at both ends, and the other end of the bellows 3 is hermetically connected to the metal inner tube 1 through a connecting flange 2, and a vacuum chamber 6 is formed between the glass outer tube 4, the corrugated tube 3 and the metal inner tube 1. The glass outer tube 4 is covered with a heat-insulating reflective layer 5; the heat-insulating reflective layer 5 has an incident window 7, which is parallel to the central axis of the glass outer tube 4 and extends from one end of the glass outer tube 4 to At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com