Compound parabolic concentrating power generation-phase change heat storage device

A compound paraboloid, phase change heat storage technology, applied in photovoltaic power generation, photovoltaic thermoelectric hybrid power generation, solar thermal power generation, etc. The overall efficiency, the heat transport loss is small, the effect of avoiding heat energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

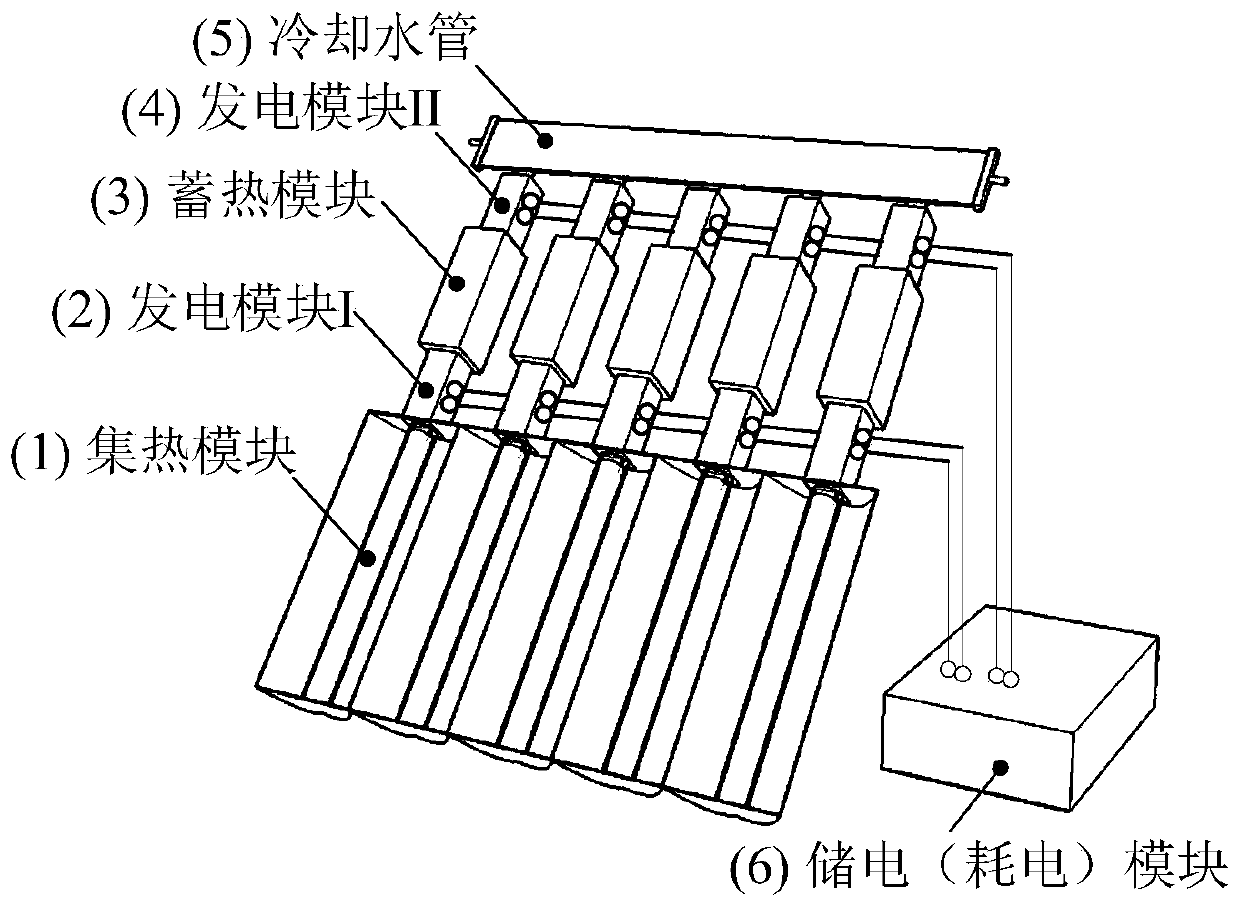

[0034] figure 1It is a schematic diagram of the three-dimensional structure of the present invention. The present invention is divided into 6 main function modules, namely heat collection module (1), power generation module I (2), heat storage module (3), power generation module II (4), cooling water pipe (5) and power storage (power consumption ) module (6). The heat collection module (1) is used to collect solar energy to provide a heat source for the power generation module I (2). At this time, the heat storage module (3) can absorb the waste heat of the power generation module I (2) during the power generation process, and provide cooling for the power generation module I. source. When the cooling water flows through the cooling water pipe (5), the heat storage module (3) can be used as a heat source for the power generation module II (4), so that the power generation module II (4) generates electric energy.

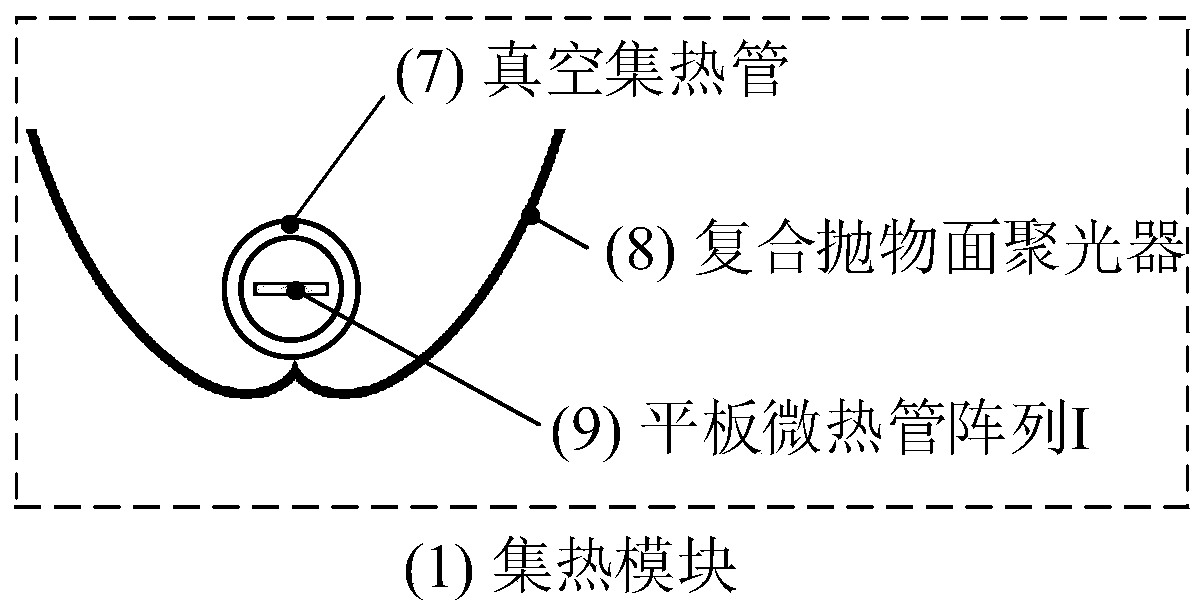

[0035] figure 2 It is a structural schematic diagram of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com