Nanometer molten salt phase-change energy storage solar furnace

A phase-change energy storage and solar furnace technology, which is applied to solar thermal devices, solar thermal energy, and solar ray concentration, can solve the problems of immaturity, short service life, and complex structure of heat-pipe solar cookers, and achieve large latent heat of phase change. , low corrosion, high heat collection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

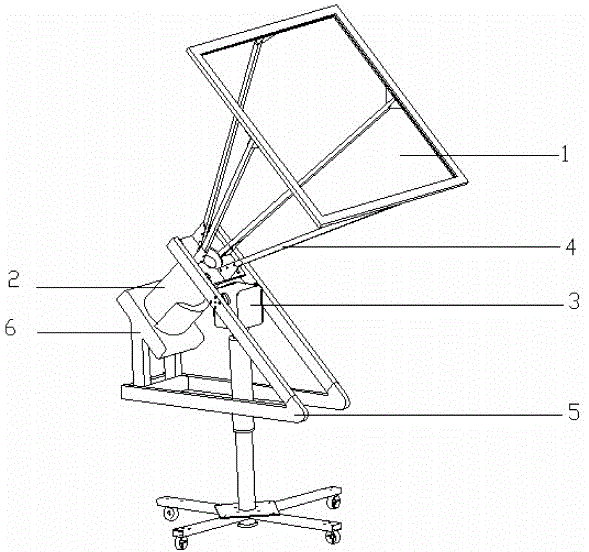

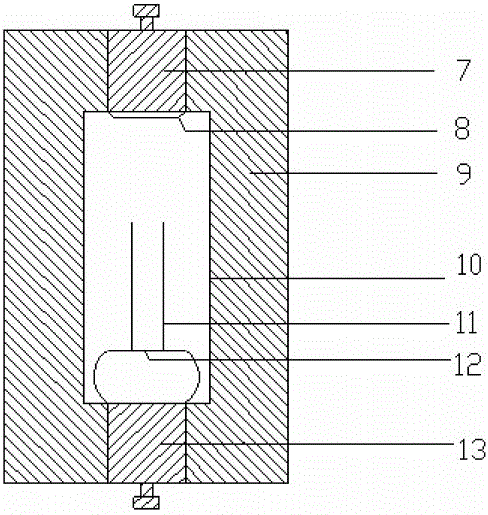

[0021] as attached figure 1 As shown, a nano-molten-salt phase-change energy storage solar furnace mainly consists of a Fresnel concentrator 1 which concentrates light from top to bottom, and a phase-change energy storage heat exchange device with a nano-molten salt composite phase-change energy storage material inside. Device 2 and latitude and longitude dual-axis tracker 3 constitute.

[0022] The Fresnel concentrator 1 is hot-pressed from polymethyl methacrylate (PMMA), which can be round or square, and the concentrating magnification is in the range of 100 to 1000 times. The Fresnel concentrator 1 is composed of several supports The pole 4 is supported, the pole 4 is fixed on the V-shaped balance bracket 5, and the V-shaped balance bracket 5 is fixed on the latitude axis of the latitude and longitude dual-axis tracker 3. The larger torque generated by the weight of the device 2.

[0023] Place the phase change energy storage heat exchanger 2 on the bottom support 6 carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com