Construction beam gesture monitoring system

A monitoring system and measurement system technology, applied in signal transmission systems, hydrostatic pressure levels, instruments, etc., can solve problems such as difficulty in guaranteeing effectiveness, increasing error rates, and potential safety hazards, achieving reliable monitoring results, avoiding operations, The effect of eliminating personal safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

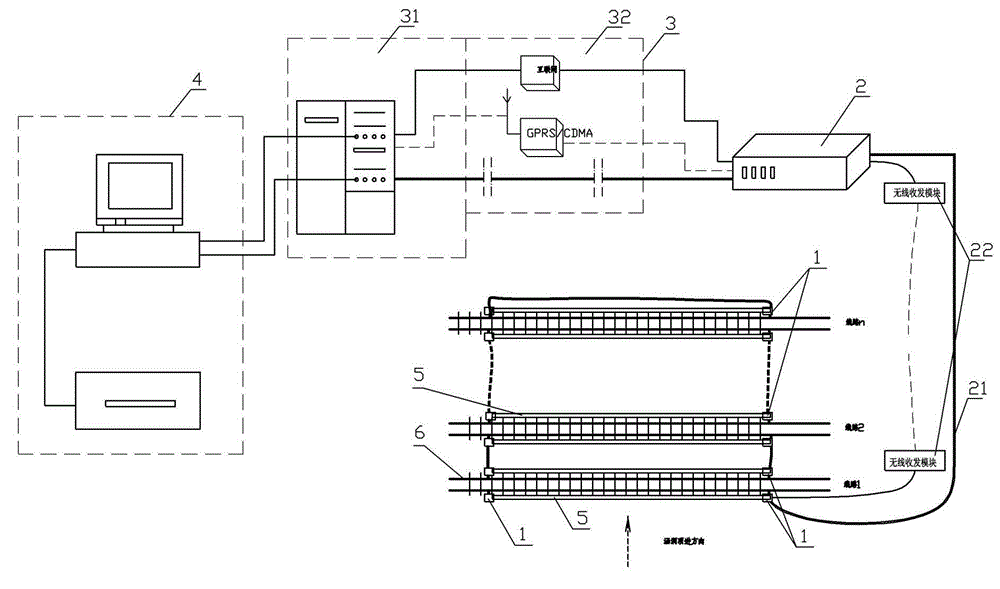

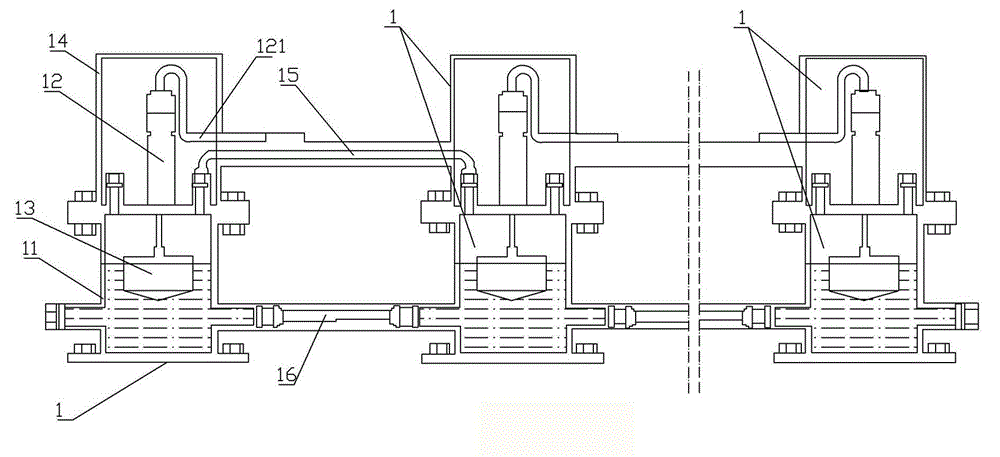

[0020] Such as figure 1 As shown, a construction beam attitude monitoring system includes a measurement system, a data transmission system 3 and a data processing system 4; the measurement system includes a displacement sensor and a static data acquisition instrument 2; the displacement sensor is a static level; figure 2 As shown, the static level includes more than two (including two) static liquid level sensing units 1; the static liquid level sensing unit 1 includes a hydraulic cylinder 11, a liquid level sensor 12, a buoy 13 and a protective cover 14. The liquid level sensor 12 is installed on the upper part of the liquid cylinder 11 and located in the protective cover 14, and the buoy 13 is located in the liquid cylinder 11 and connected with the liquid level sensor 12 through the connecting rod (at the same time, it is subject to the buoyancy of the liquid in the liquid cylinder 11) , the liquid level sensor 12 can detect the height position of the buoy 13, and transmit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com