Determination method for activity coefficient of solute component in metal melt at high temperature

A technology of activity coefficient and metal melt, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unknown activity coefficient of oxides, and achieve the effect of avoiding changes in slag composition, avoiding errors, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

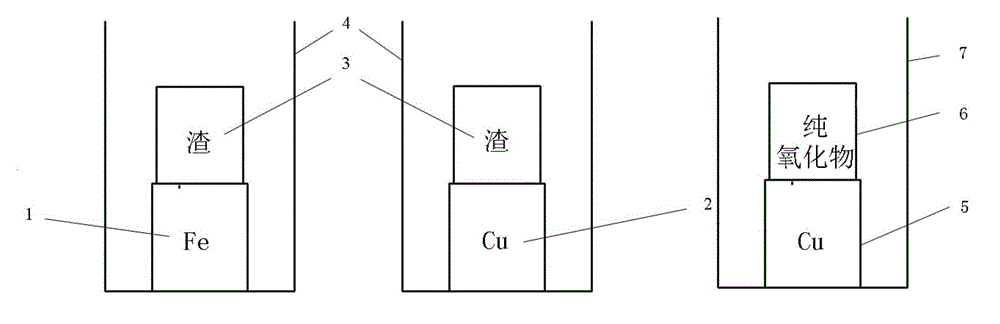

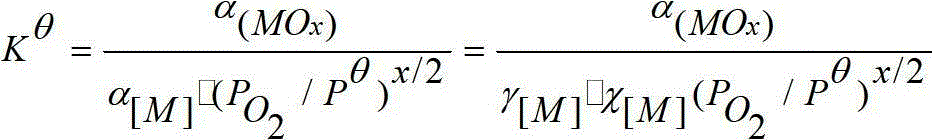

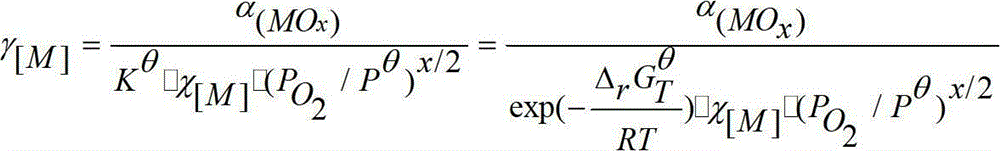

Method used

Image

Examples

Embodiment Construction

[0027] When measuring the activity coefficient of solute component Nb in Fe-Nb-C-O melt, Mo crucible was selected as the reference crucible. Considering the low solubility of Nb in Cu liquid, Cu was selected as the reference metal. The two experimental crucibles also used MgO crucibles, respectively mixed with Cu powder and Fe powder of the same quality, and then mixed with CaO-Al with the same quality and the same ratio. 2 o 3 -SiO 2 -Nb 2 o 5 - MgO slag.

[0028] Put the above-mentioned two crucibles filled with experimental raw materials together with the reference crucible into a high-temperature furnace for equilibrium reaction. After the experiment, the content of Nb in Cu in the reference crucible and the content of Nb in Cu and Fe in the experimental crucible can be analyzed respectively. content, the activity coefficient and other thermodynamic properties of the solute component Nb in the Fe-Nb-C-O melt were obtained under the experimental conditions.

[0029] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com