Dual-beam large-spot collimated irradiation implementation method used in special environment

An implementation method and double beam technology, applied in optics, optical components, instruments, etc., can solve the problems of inability to realize, increase the difficulty of window processing and manufacturing cost, and achieve the effect of reducing the difficulty of design and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

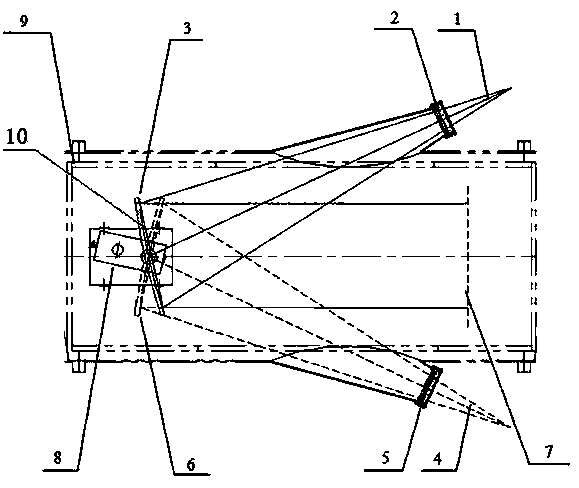

[0016] The convenient and quick realization of the collimated irradiation based on the double-beam large spot in a special environment is the key point of the present invention. The specific implementation method of the present invention will be further described below in conjunction with the accompanying drawings:

[0017] Such as figure 1 As shown in the schematic diagram of the structure principle of the present invention, the laser beam I is incident into a confined space 9 through the window mirror I, and the collimating mirror 10 receives the incident laser beam at position A and performs beam expansion and collimation, so that the thin laser beam has a large spot The target 7 is irradiated in a collimated way; then, adjust the collimating mirror rotating platform 8, the collimating mirror turns to position B, the laser beam II enters through the window mirror II, and the collimating mirror receives the incident laser beam at position B And perform beam expansion and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com