Detection method for checking correctness of mounting of lens of polarization glasses

A technology for lens installation and polarized glasses, applied in optics, optical components, testing optical performance, etc., can solve problems such as failure to detect glasses, angle deviation of polarized light absorption axis, failure to effectively detect problems, etc., to prevent false leak detection The effect of detecting phenomenon and compensating for angle deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

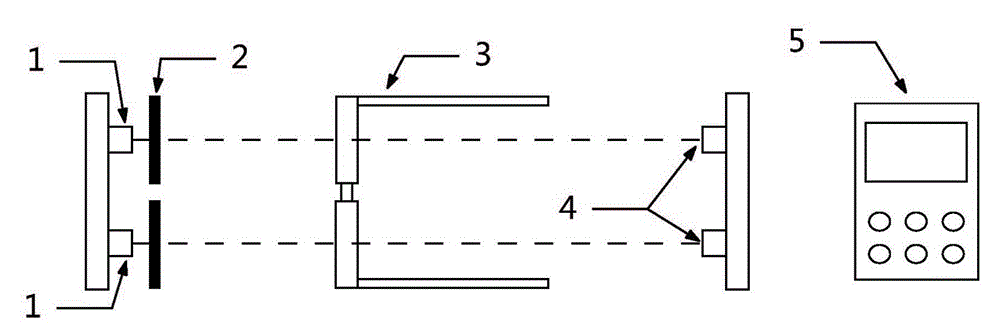

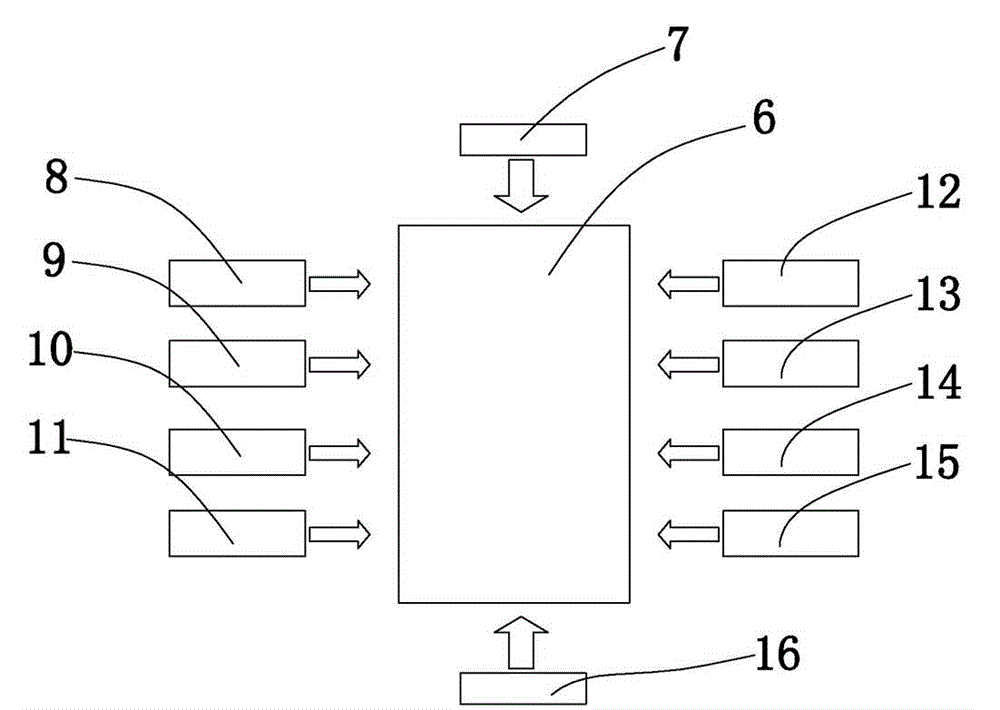

[0018] The LED lamp emission source 1 is a commercially available white LED lamp with a color temperature of 4200k-6000k and a power of 3W. The reference polarizer 2 is a polarizer whose polarization direction is opposite to that of the spectacle lens to be tested and whose absorption axis is relatively vertical. The light receiver 4 is connected to The model corresponding to the LED lamp emission source 1 is PD15-22T light receiver, and the input terminal 6 of the readout judgment display device 5 is wired with the light receiver 4, wherein the electric signal digital conversion unit 7 in the readout judgment display device 5 , the setting unit 8, the comparison unit 9, and the readout determination unit 10 are medium-scale central processing units, and the display screen 11 is a liquid crystal display screen.

[0019] The reference polarizer 2 is 10mm away from the LED lamp emission source 1, the tested glasses 3 are 10mm away from the reference polarizer 2, and the readout j...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap