Low-temperature insulator and manufacturing method thereof

A technology for low-temperature insulators and main insulation, applied in the direction of insulators, lead-in/through-type insulators, superconductor elements, etc., can solve problems such as damage and poor reliability, and achieve the effects of improved reliability, low cost, and reliable sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

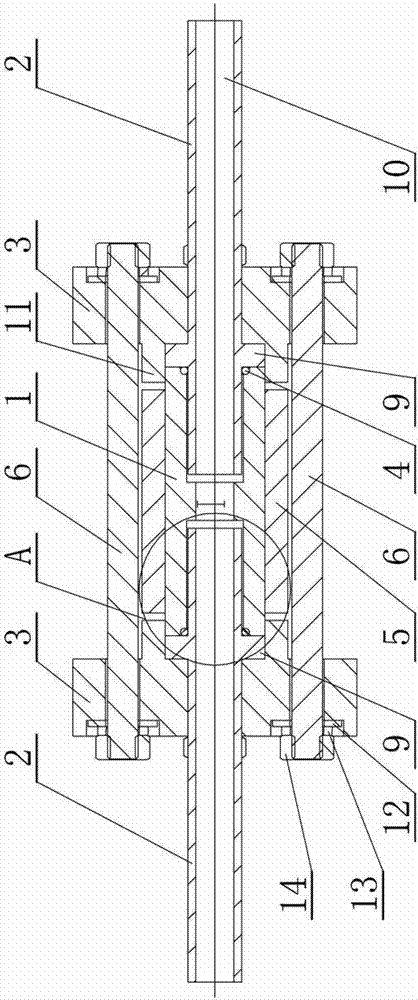

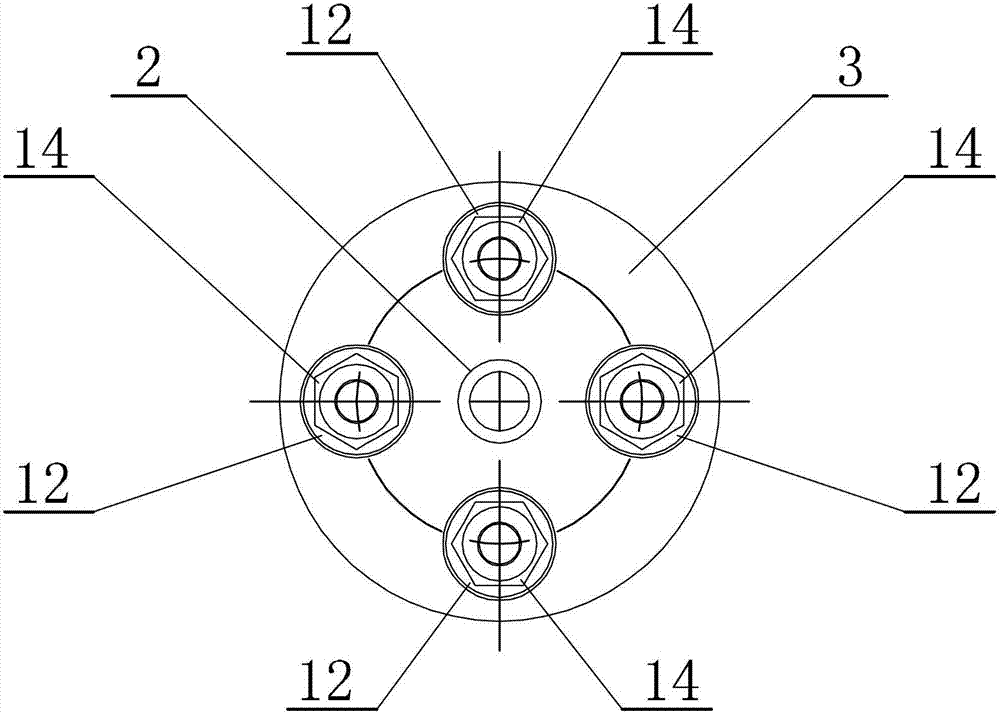

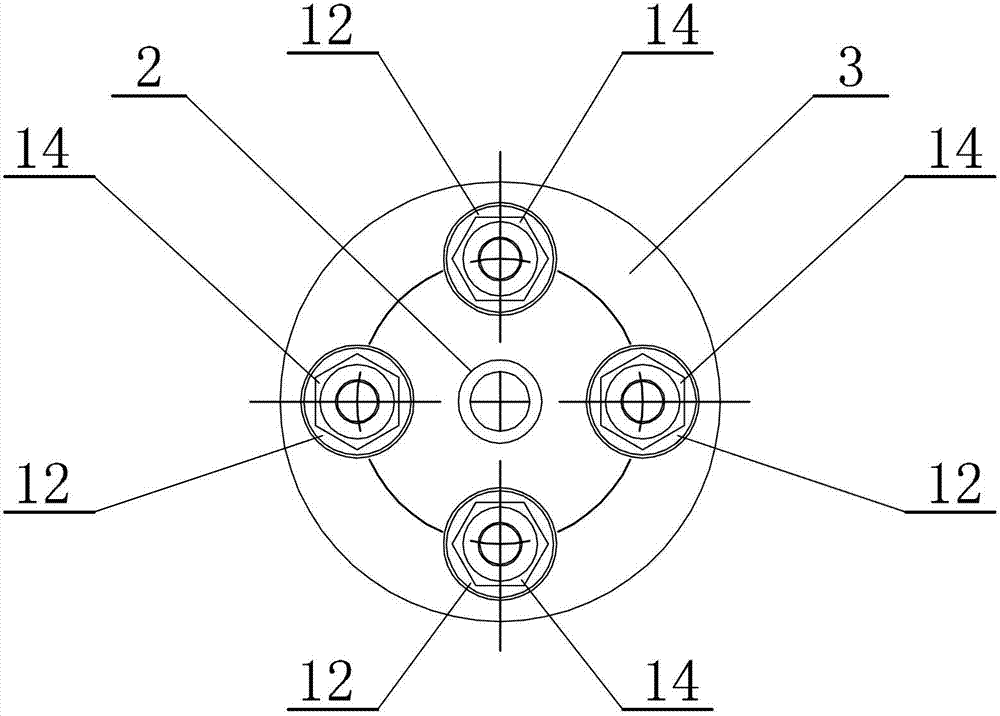

[0015] Specific implementation mode one: combine figure 1 , figure 2 , image 3 with Figure 4 This embodiment is described. The low-temperature insulator described in this embodiment includes a main insulating pipe 1, a sleeve 5, two connecting pipes 2, two insulating pressure plates 3, two indium rings 4 and four tension screws 6. The sleeve 5 is set on the outer surface of the main insulating pipe 1, and the two ends of the main insulating pipe 1 are respectively provided with an insulating pressure plate 3 and a connecting pipe 2, and each insulating pressure plate 3 is processed with an axial through hole 7 and four tie rods Through holes 8, each connecting pipe 2 is respectively processed with a shoulder 9, each connecting pipe 2 passes through the axial through hole 7 on the corresponding insulating pressure plate 3 and is fixedly connected to the inside of the main insulating pipe 1, each connecting pipe The shoulder 9 on 2 is in close contact with the main insulat...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Note that in this embodiment, the length of the connecting pipe 2 located outside the main insulating pipe 1 is 30-40 mm, and the length of the connecting pipe 2 located inside the main insulating pipe 1 is 15-20 mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Note that, in this embodiment, the inner diameter of each connecting pipe 2 is less than 5 mm, and the outer diameter of each connecting pipe 2 is less than 7 mm. Such size setting can not only ensure sufficient flow of cryogenic fluid to flow to the current leads, but also minimize the area of the insulating sealing interface. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com