Wind power generator structure facilitating air gap adjustment and air gap adjustment assembly method of wind power generator

A technology of wind power generator and assembly method, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems affecting the stable operation and service life of motors, achieve convenient and quick adjustment, reduce unilateral magnetic pull, reduce vibration and Effects of Electromagnetic Noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

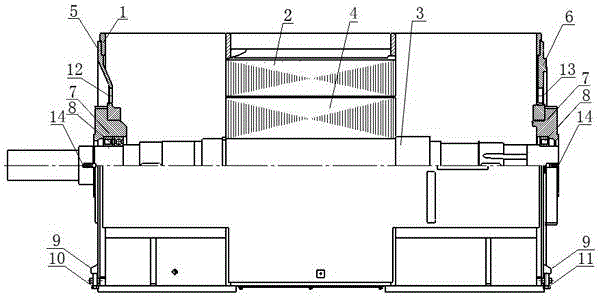

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] A wind-driven generator air gap adjustment assembly method, it comprises the following steps:

[0016] A. Design the joints of the generator base 1 and the front and rear end covers 6 to adopt clearance fit, and the clearance value is 1-3mm;

[0017] B. Select 6 to 10 detection points evenly along the circumferential direction symmetrically at the front and rear ends of the stator 2 and rotor 4, and measure the stator 2 and rotor at the front and rear ends of the same symmetrical detection point through the air gap measurement hole A12 and air gap measurement hole B13 respectively The air gap value between 4;

[0018] C. According to the measured air gap value, determine the position of the eccentricity, and adjust the adjusting bolt A10 and the adjusting bolt B11 on the machine base 1 at the same time, the adjusting bolt A10 withstands the bridge 9 on the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com