Flushing method and system for preventing deposits from forming inside a fuel pump

A technology of flushing system and fuel injection system, which is applied in the fields of fuel injection pump and flushing fuel injection pump, fuel pump and flushing fuel pump, can solve the problems of difficulty in functioning and easy solidification of fuel oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

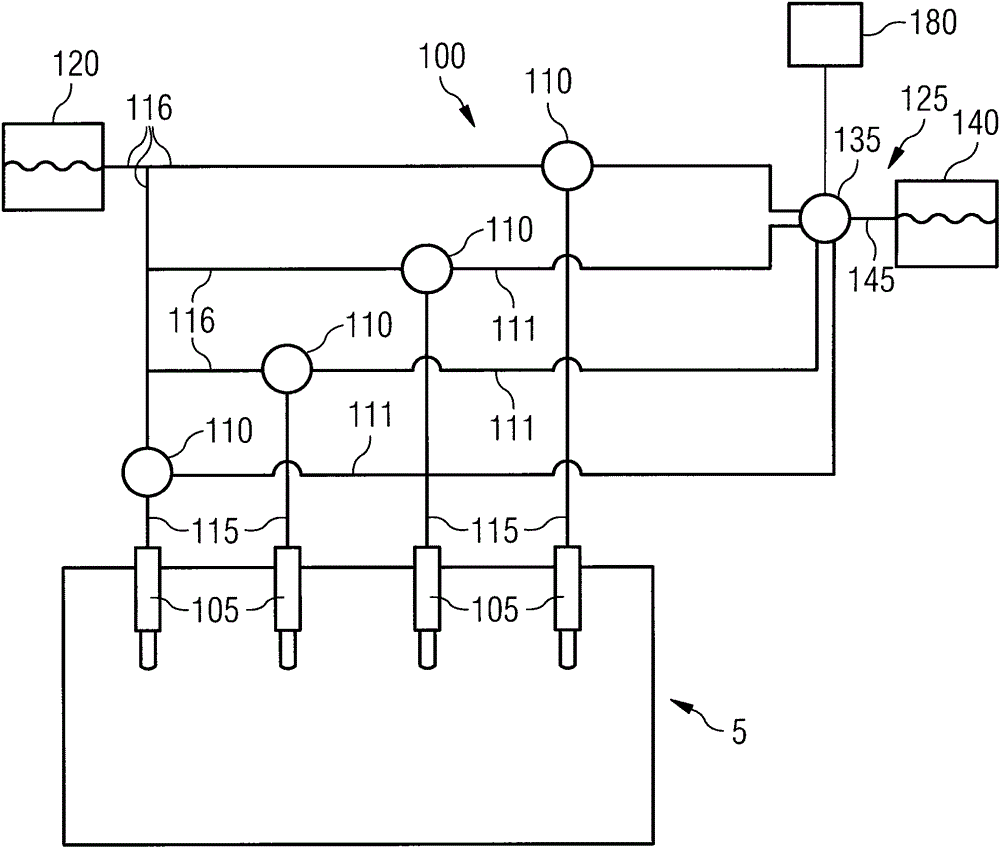

[0026] figure 1 A block schematic diagram of an exemplary embodiment of a fuel injection system 100 configured to supply fuel, such as heavy fuel oil, to nozzles 105 of a large internal combustion engine 5 is shown. According to this exemplary embodiment of fuel injection system 100 , each nozzle 105 may be connected to an associated fuel injection pump 110 via a high pressure fuel line 115 . Alternatively, one fuel injection pump 110 may be configured to supply fuel, such as heavy fuel oil, to multiple fuel nozzles 105 .

[0027] Each fuel injection pump 110 may be connected to a fuel reservoir 120 via a fuel supply line 116 . Additionally, each fuel injection pump 110 may be connected to a flushing system 125 via a flushing fluid supply line 111 . In other exemplary embodiments of the present invention, the figure 1 The arrangement shown is modified in that only one high-pressure fuel pump is provided instead of several pumps 110 . The one high pressure fuel pump may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com