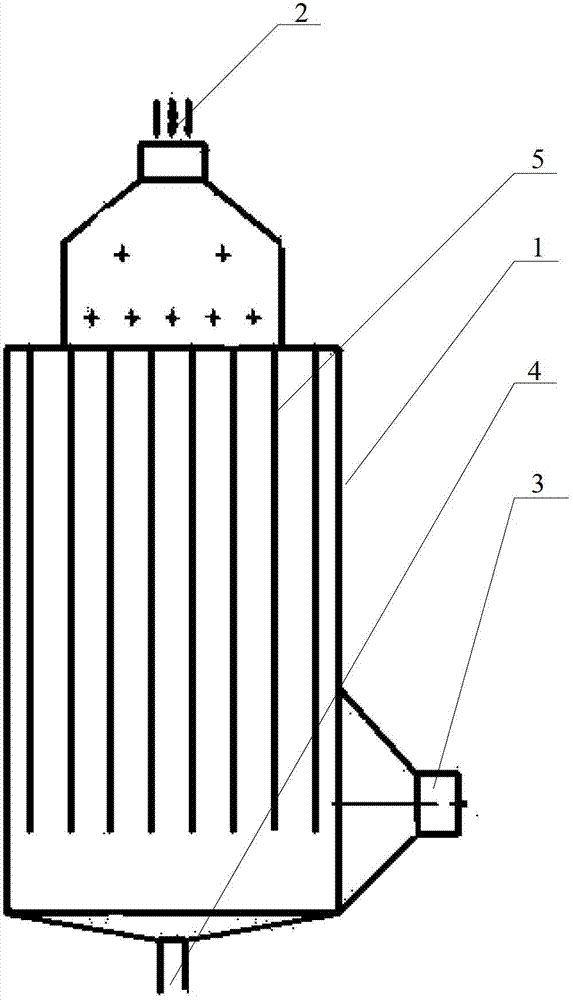

Vertical type wet process electric dust collector flow field optimizing device

A technology of electrostatic precipitator and optimization device, applied in the field of electrostatic precipitator, which can solve problems such as uneven distribution of gas, sloshing, and secondary pollution of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the invention is to provide a flow field optimization device for a vertical wet electrostatic precipitator, which prevents the airflow in the dust collector from being deflected.

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

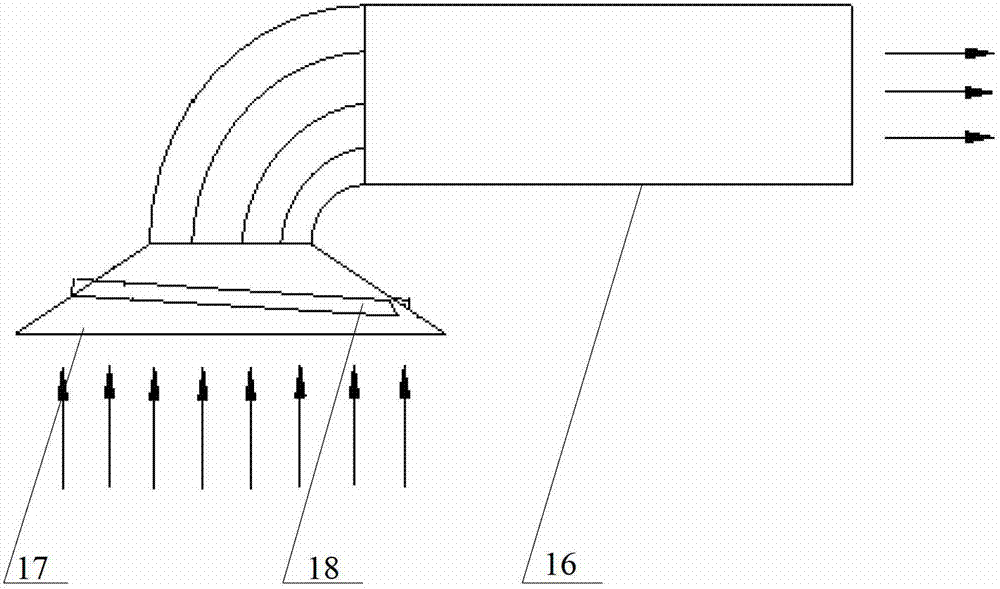

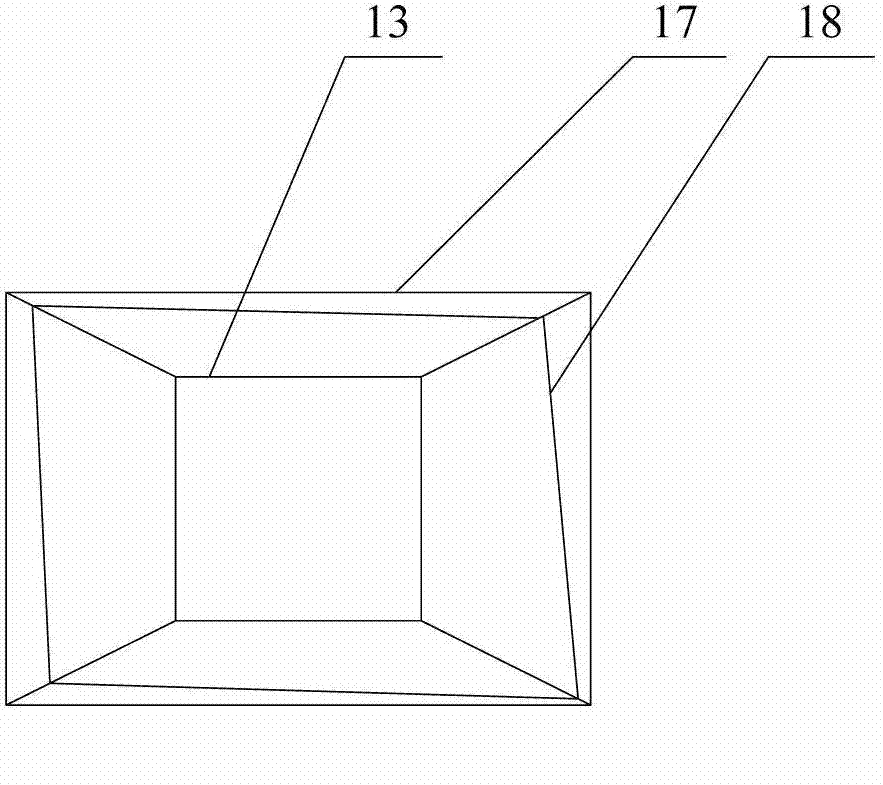

[0027] Please refer to Figure 2-Figure 4 , the embodiment of the present invention discloses a flow field optimization device for a vertical wet electrostatic precipitator, including a dust collector housing provided with a gas inlet 12, a gas outlet 13 and a water discharge port 14, and a dust collector housing 11. The dust collector plate 15 also includes an exhaust channel 16 connected to the gas outlet 13 , the inlet end of the exhaust channel 16 is opened downwards and its central axis coincides with the central axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com