Tension rod structure of injection molding machine

A tie rod structure and technology of injection molding machine, applied in the field of tie rod assembly of injection molding machine clamping mechanism, can solve the problems of broken threaded end of tie rod and short service life, and achieve the effect of prolonging service life, small volume and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

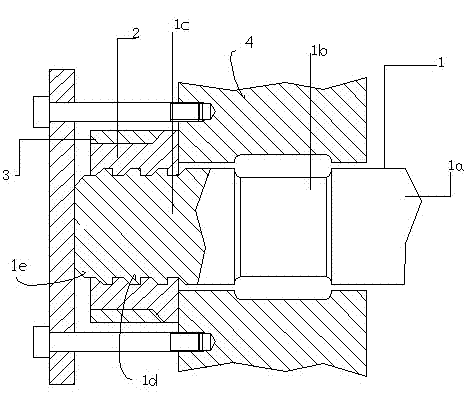

[0027] The serial numbers and names of the above drawings are: tie rod 1, smooth section 1a of tie rod, stress groove 1b, mold adjusting thread section 1c, large pitch tooth body 1d, head end 1e of mold adjusting thread section, tie rod mold adjusting nut 2, outer ring 3 .

[0028] as attached figure 1 As shown, a tie rod structure of an injection molding machine according to the present invention includes a tie rod 1 and a tie rod mold adjusting nut 2. The tie rod 1 includes a mold adjusting threaded section 1c, wherein a large mold is formed on the mold adjusting threaded section 1c. Pitch tooth body 1d, the pull rod mold adjusting nut 2 is screwed with the mold adjusting thread section 1c through the large pitch tooth body 1d, and a large fillet transition is used at the step or the undercut.

[0029] In the embodiment, the pitch of the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com