4R coagulation water treatment process

A process method and water treatment technology, applied in the field of water treatment, can solve problems such as it is difficult to adapt to the miniaturization of equipment and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

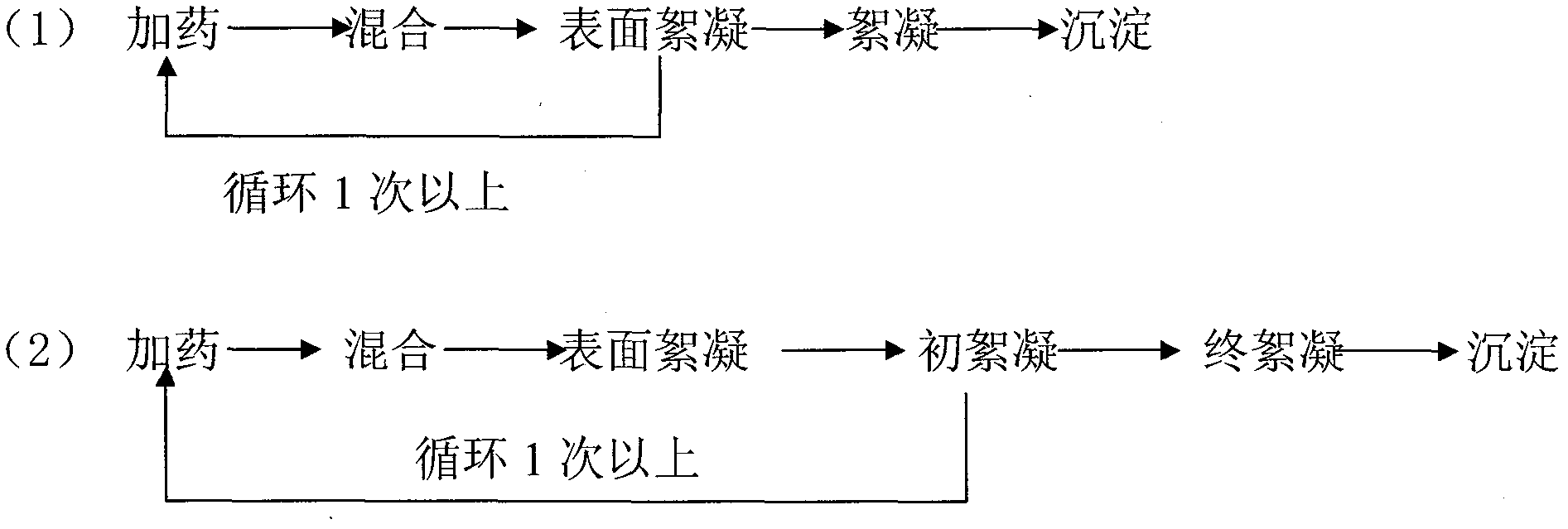

[0023] There are mainly two implementation methods for the 4R coagulation water treatment process, see attached figure 2 . We have repeatedly verified the above two coagulation processes in experiments.

[0024] Figures and Examples

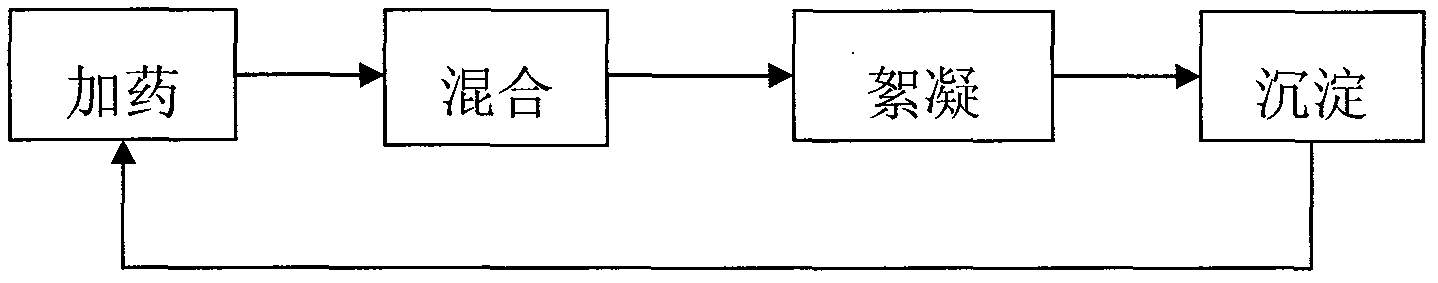

[0025] attached figure 1 It is a process flow diagram of repeated coagulation used by some waterworks. attached figure 2 These are two typical water treatment processes that can be used to implement 4R coagulation water treatment.

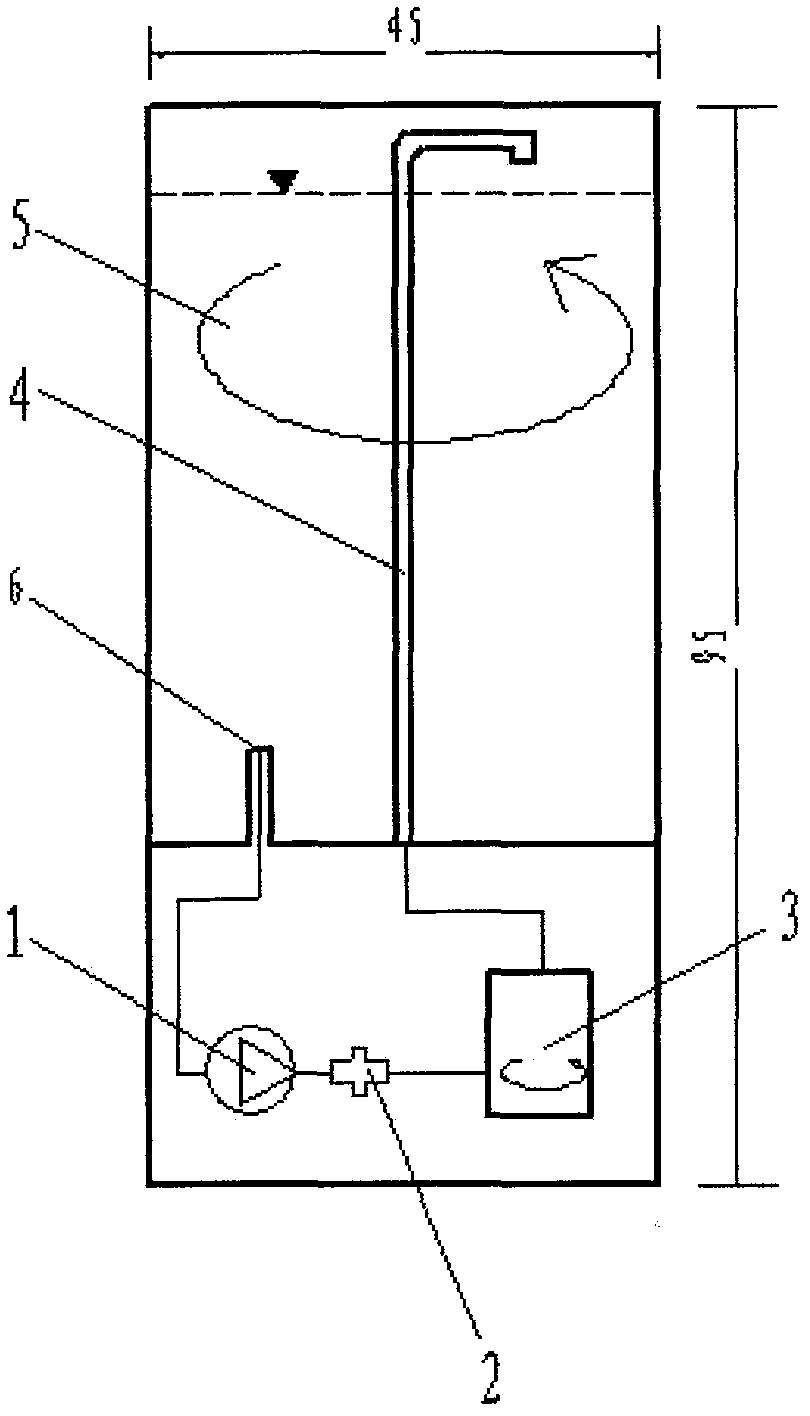

[0026] attached image 3It is a principle schematic diagram of an embodiment of a household water purification device produced by adopting the patented technology of the present invention. The treatment barrel 5 in the figure is an H-shaped stainless steel barrel, the size of the barrel is φ45X(65+30)cm, the upper part of the barrel has a volume of about 100L, and the lower part of the barrel is the equipment layer, circulation pump 1, dosing water cone 2, mixing device 3 etc. are all installed in the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com