Steel coil preheating device

A preheating device, steel coil technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of affecting the quality of steel coils, long heating time, safety hazards, etc., and achieve easy control of heating temperature and fast heating and heating speed. , the effect of solving security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

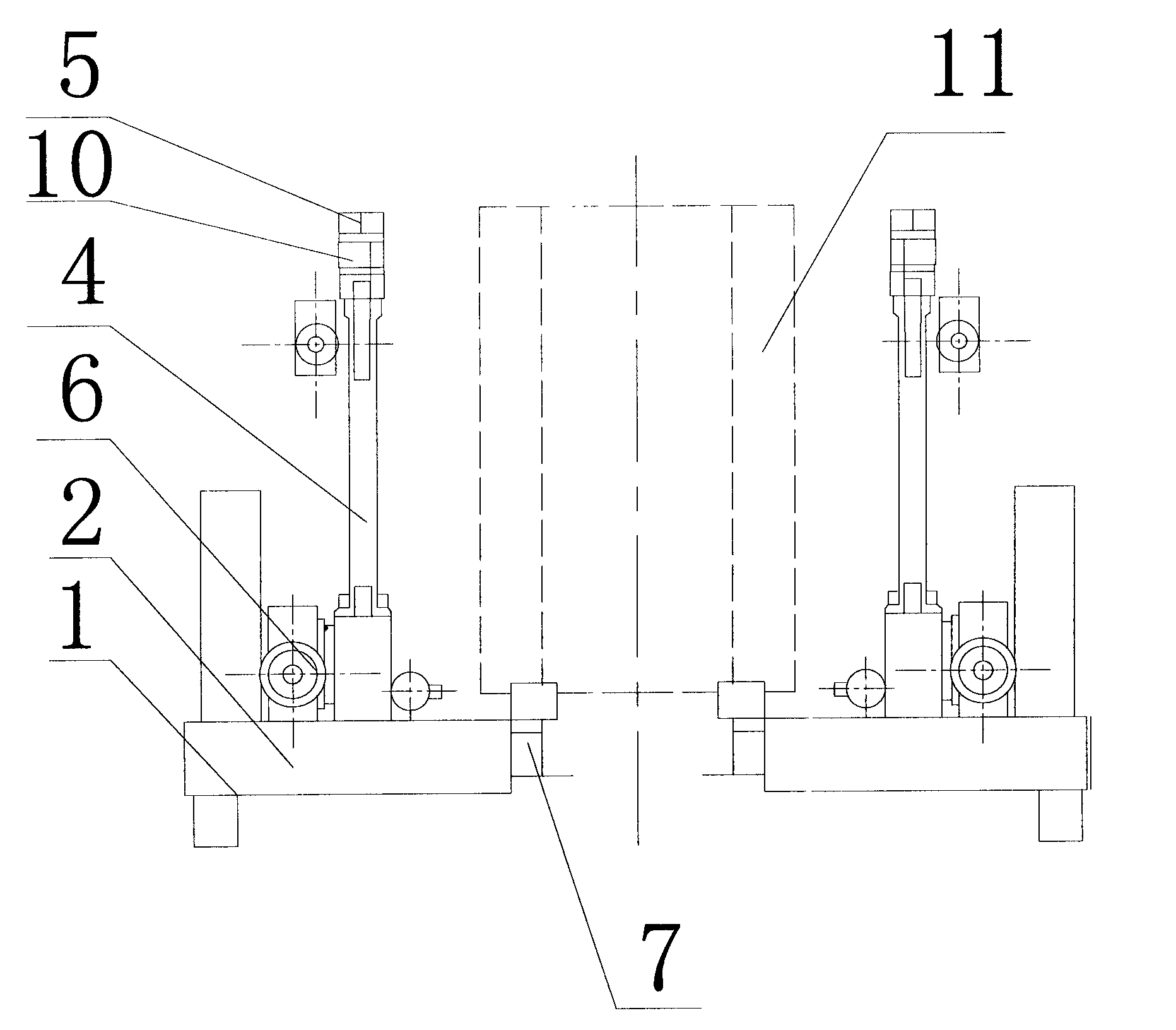

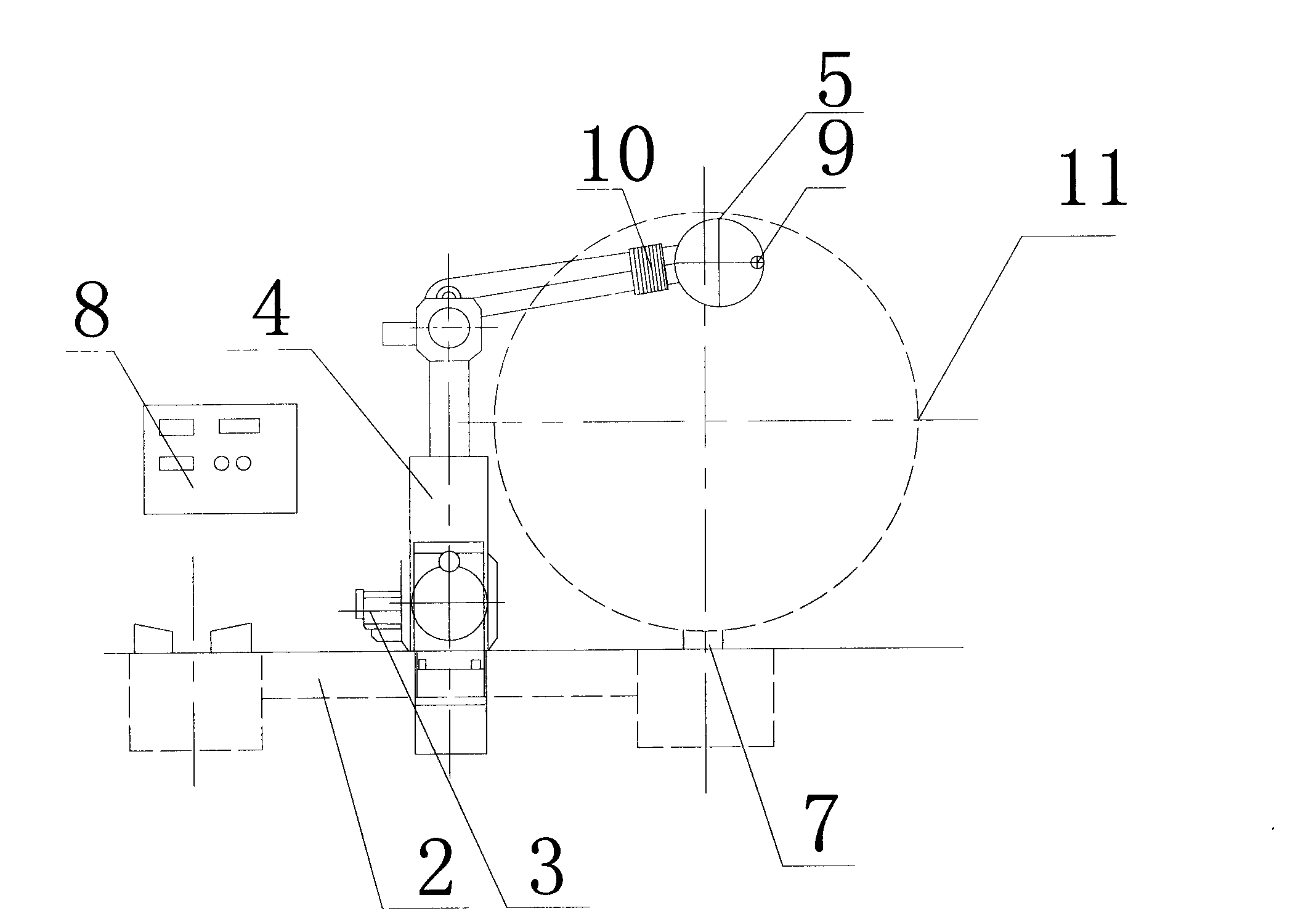

[0013] Such as figure 1 and figure 2 As shown, a steel coil preheating device includes an underframe 1, a guide rail 2, a moving seat 3, a manipulator 4, a heating plate 5, and a front and rear driving device 6 for the moving seat, and the underframe 1 is fixed on the steel coil 11 conveyor 7, The guide rail 2 is fixed on the chassis 1, the bottom of the manipulator 4 is fixed on the moving seat 3, the front end of the manipulator 4 is connected to the heating plate 5, the front and rear driving devices 6 of the moving seat are installed at the bottom of the moving seat 3, and the heating plate 5 is an electromagnetic heating plate. The electromagnetic heating plate is connected with an intelligent control device 8, and the heating plate 5 adopted is an electromagnetic heating plate, and the traditional flame heating is replaced by the electromagnetic heating plate, which solves the safety hazard caused by heating with an open flame, and the heating speed is fast and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com